Telematics is the buzzword of the cold chain logistics industry in 2025. Companies are shifting to vehicle tracking technologies to deliver time-sensitive goods. This ensures items like seafood, medicines, vaccines, and frozen products remain safe throughout the journey.

Let’s explore the fundamentals of vehicle tracking in cold chain logistics, including its applications, benefits, and more.

What is Telematics?

Vehicle tracking combines telecommunications and informatics to monitor and manage vehicles, equipment, and assets. In cold chain logistics, it refers to the use of advanced technologies to collect, transmit, and analyze data from refrigerated transport vehicles. This system ensures that perishable goods remain within the required temperature ranges during transit.

The components of a vehicle system typically include:

- GPS tracking devices.

- Sensors for temperature, humidity, and vibration monitoring.

- Onboard diagnostics systems.

- Cloud-based platforms for real-time data processing and reporting.

Importance in Cold Chain Logistics

Vehicle tracking is essential to transport goods globally. Here’s how it enables seamless tracking and visibility:

1. Ensures Temperature Compliance

One of the most critical aspects of cold chain logistics is maintaining the correct temperature for products. Telematics enables real-time temperature monitoring, ensuring products like vaccines, frozen foods, and chemicals remain within the required range.

2. Real-Time Tracking and Visibility

It provides end-to-end visibility of shipments by integrating GPS tracking with real-time monitoring. Logistics managers can track the exact location of vehicles, ensuring faster decision-making during route changes or delays.

3. Enhances Operational Efficiency

By monitoring fleet performance and driver behaviour, it identifies inefficiencies such as excessive idling, over-speeding, or unoptimised routes. Addressing these issues reduces fuel costs and improves delivery timelines.

4. Minimises Product Loss

In cold chain logistics, temperature excursions can lead to product spoilage, resulting in significant financial and reputational losses. Telema alerts stakeholders immediately if temperatures deviate from set parameters, enabling swift corrective action.

5. Regulatory Compliance

Governments and industries impose strict regulations for transporting temperature-sensitive goods. Vehicle telemetry provides comprehensive records and reports that help companies comply with standards like GDP (Good Distribution Practices) and FSMA (Food Safety Modernization Act).

6. Boosts Customer Satisfaction

Fleet tracking technology ensures real-time temperature monitoring and precise delivery schedules to enhance transparency and improve customer satisfaction.

Solving Cold Chain Logistics Challenges

Here are the main challenges that vehicle tracking systems solve:

1) Data Collection:

Sensors installed in vehicles measure key parameters like temperature, humidity, and shock levels.

2) Data Transmission:

The data collected is transmitted via telecommunication networks to cloud-based platforms.

3) Data Analysis:

Advanced analytics tools process the data, providing actionable insights for fleet and logistics managers.

4) Alerts and Reporting:

The system sends immediate alerts for anomalies, such as temperature deviations or route delays. Customisable reports are also generated to ensure compliance and performance evaluation.

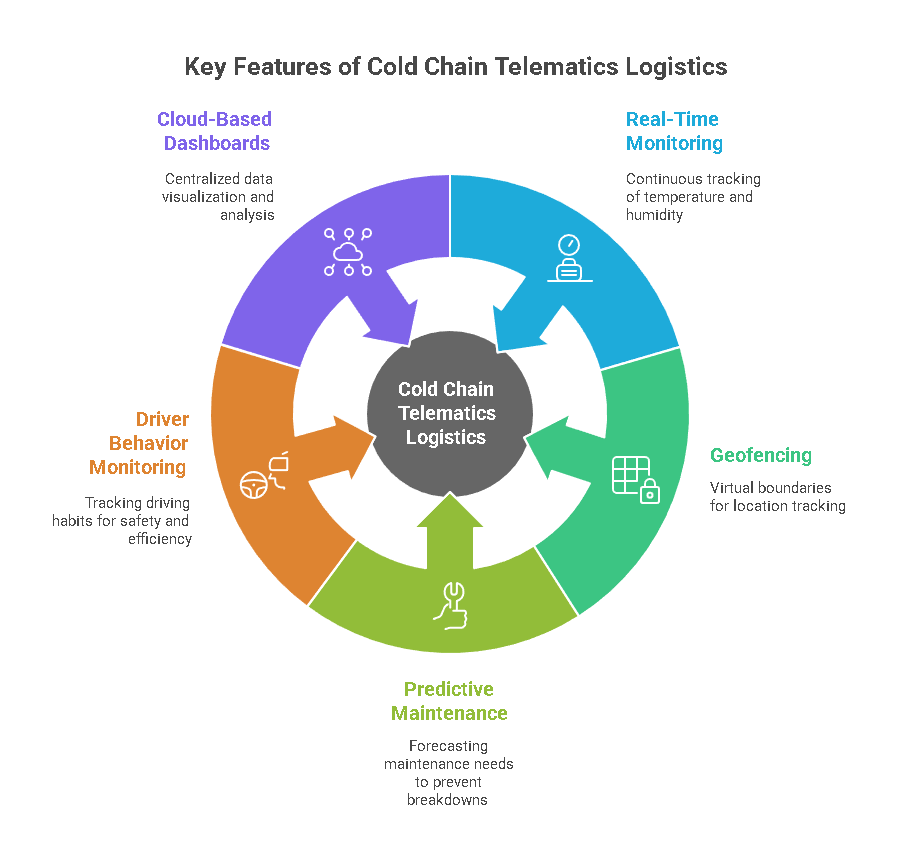

Key Features of Cold Chain Telematics Logistics

Cold chain monitoring is vital to safeguard the quality of goods and services. Here are the key features listed below:

1. Real-Time Temperature and Humidity Monitor

Continuously monitor environmental conditions inside refrigerated vehicles.

2. Geofencing Capabilities

Alerts when vehicles leave predefined geographic areas, ensuring route compliance.

3. Predictive Maintenance

Monitors vehicle health, reducing the risk of breakdowns during transit.

4. Driver Behavior Monitoring

Tracks metrics like speed, braking, and idling to improve safety and fuel efficiency.

5. Cloud-Based Dashboards

Provide stakeholders with real-time insights and historical data for better decision-making.

Benefits of Telematics in Cold Chain Logistics

Temperature and vehicle tracking have many benefits. Here are a few listed below:

1. Cost Savings

Telematics reduces fuel consumption and maintenance costs by identifying inefficiencies in fleet operations.

2. Improved Product Integrity

Maintaining consistent temperature levels ensures the quality and safety of temperature-sensitive goods.

3. Enhanced Security

Real-time tracking prevents theft or unauthorised access, especially during long-haul transport.

4. Data-Driven Decision-Making

Access to historical and real-time data helps logistics managers identify trends, optimise routes, and plan better for future operations.

5. Sustainability

Optimised routes and reduced fuel consumption contribute to lower carbon emissions, aligning with sustainability goals.

Challenges of Implementing Cold Chain Telematics

While cold chain vehicle fleet tracking offers significant advantages, implementing it can be challenging. These hurdles can make adoption difficult, especially for businesses operating with tight budgets or limited technological expertise. Below are the primary challenges and ways to address them.

1. High Initial Investment

Implementing a telemetry system requires a significant upfront investment in hardware, software, and infrastructure. Costs include the installation of GPS trackers, temperature and humidity sensors, telecommunication systems, and cloud-based platforms. Additionally, businesses may need to upgrade their existing fleet to ensure compatibility with vehicle solutions.

- Solution: Companies can start with scalable solutions, allowing gradual implementation based on their budget. Partnering with telematics service providers that offer flexible payment models, like subscription-based plans, can also reduce financial strain.

2. Data Overload and Management

Telematics systems generate vast amounts of data, including real-time information on temperature, location, vehicle performance, and driver behaviour. Managing and analysing this data effectively can be overwhelming, especially for companies without dedicated IT teams.

- Solution: To address this challenge, businesses should invest in user-friendly dashboards and analytics tools that simplify data visualisation. Employing AI-powered solutions can also help filter and interpret critical data points automatically.

3. Integration with Existing Systems

Many companies already use supply chain management or warehouse management systems, and integrating with these platforms can be challenging. Compatibility issues between software solutions and legacy systems often arise, resulting in delays and inefficiencies.

- Solution: Businesses should prioritise vehicle tracking providers that offer API integrations and customisable solutions. Collaboration between IT teams and telematics vendors can streamline the integration process and ensure systems work seamlessly together.

4. Training and Adoption

Cold chain fleet management introduces new technologies that require training for drivers, fleet managers, and logistics teams. Employees may resist change or struggle to adapt to advanced tools, slowing down the implementation process.

- Solution: Investing in employee training programs is essential. Providing hands-on demonstrations and ongoing support can boost confidence and encourage the adoption of fleet tracking systems. Involving employees early in the decision-making process can also reduce resistance to change.

5. Connectivity Issues

Telematics relies heavily on stable internet or cellular connectivity for real-time data transmission. However, vehicles travelling through remote or rural areas often experience connectivity disruptions, leading to data gaps.

- Solution: Using solutions with offline capabilities can address connectivity issues. These systems store data locally and upload it to the cloud once connectivity is restored, ensuring no critical information is lost.

To overcome these challenges, businesses should choose scalable telematics solutions, partner with experienced providers, and invest in employee training.

Future of Telematics in Cold Chain Logistics

The future is poised for innovation, driven by advancements in IoT, AI, and 5G technology. These advancements will enhance connectivity, improve data accuracy, and enable predictive capabilities. Emerging trends include:

- Blockchain Integration: For secure and transparent supply chain records.

- AI-Driven Insights: To predict equipment failures or temperature fluctuations before they occur.

- 5G Connectivity: Enabling faster data transmission, even in remote locations.

Conclusion

Telematics provide real-time data about the condition of goods, reducing spoilage risk for temperature-sensitive cargo. It is an important part of the modern supply chain communications network. Do you need to resolve your supply chain bottlenecks? look no further than Qodenext to supercharge your supply chain systems.

FAQs – Cold Chain Telematics

1. What is telemetry, and how does it apply to cold chain logistics?

Telematic technology is the integration of telecommunications and informatics to monitor and manage assets. In cold chain logistics, it ensures real-time monitoring of temperature, location, and other critical parameters to maintain product integrity.

2. What are the key benefits of cold chain vehicle fleet tracking?

Key benefits include temperature compliance, real-time tracking, operational efficiency, reduced costs, and enhanced customer satisfaction.

3. How does fleet tracking improve regulatory compliance?

Telematics generates detailed reports and records that help businesses comply with regulations like GDP and FSMA by ensuring consistent temperature monitoring and product handling.

4. What are the challenges of implementing asset tracking in cold chain logistics?

Challenges include high initial costs, data management complexities, system integration issues, and the need for employee training.

5. What is the role of IoT in vehicle management?

IoT devices enhance telemetry by enabling seamless data collection, transmission, and analysis, providing real-time insights into critical supply chain parameters.