Your phone buzzes—a long-awaited delivery notification arrives, right on schedule. But have you ever wondered how companies consistently deliver the correct products to the right place, exactly when you expect them? The answer lies in effective supply chain management: a complex, behind-the-scenes process that orchestrates the movement of goods from suppliers to customers.

Today, with the rapid advancement of technology, machine learning is revolutionizing supply chain management, transforming it into a smarter, faster, and more efficient system. In this blog, we’ll dive into how machine learning is reshaping supply chain management and the remarkable impact it’s having on the industry. Let’s get started!

What is Machine Learning?

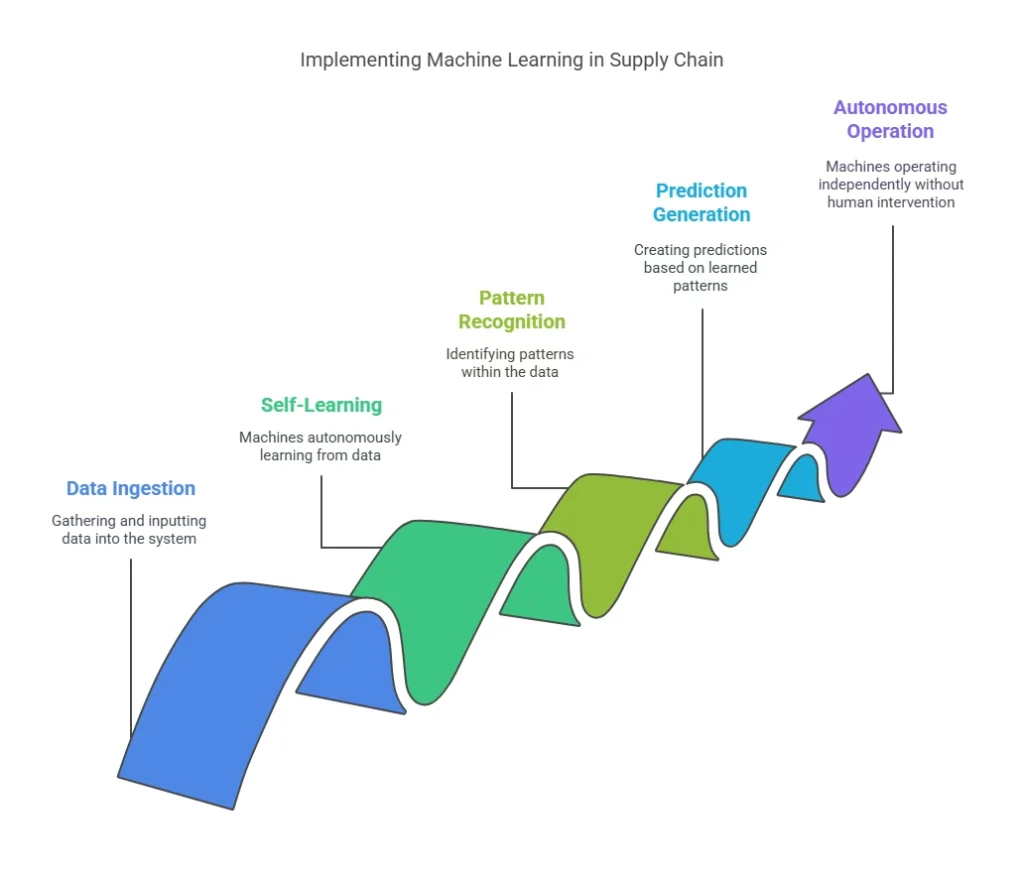

Machine learning (ML) stands as a pivotal component within the realm of AI, empowering machines to autonomously glean insights from data and past experiences, thereby generating predictions with minimal human intervention.

ML techniques enable computers to operate independently, free from explicit programming. These ML applications ingest fresh data, self-learn, evolve, and adapt over time.

Employing machine learning within supply chain development involves harnessing algorithms to sift through vast data sets, and recognizing patterns through iterative processes. Its formidable capabilities render it an optimal solution for addressing critical challenges within some of the largest supply chain enterprises.

Machine Learning Applications in Supply Chain Management

The advantages of integrating machine learning into supply chain management extend across diverse sectors, encompassing retail to humanitarian efforts. Here, we delve into four key use cases that underscore the significance for companies contemplating the adoption of ML-driven logistics enhancement.

1. Inventory Management

As consumer preferences shift towards online shopping, the demand for detailed product availability information intensifies. Machine learning enables unprecedented levels of prediction and visibility throughout the supply chain. It empowers businesses with real-time insights and granular demand forecasting capabilities.

2. Distribution Node Planning

Advanced predictive analytics, coupled with computer vision and integrated systems, enable precise forecasting and agile decision-making. With consumer expectations on the rise, businesses are shifting towards distribution centers. This necessitates operational complexity effectively managed by machine learning technologies in trend.

3. Shipping Optimization

Machine learning empowers businesses to optimize shipping processes, from tracking shipments to route optimization, ensuring timely and intact deliveries. Enhanced visibility throughout the shipping journey, coupled with last-mile tracking capabilities, contributes to improved customer experiences and loyalty.

4. Returns and Reverse Logistics

By leveraging accurate forecasting and logistical planning, machine learning mitigates losses and brings order to the complexities of reverse flow scenarios. Machine learning ignites innovation in the supply chain, tackling longstanding and emerging challenges to enhance efficiency and resilience in modern business operations.

9 Ways Machine Learning is Revolutionizing Supply Chain Management

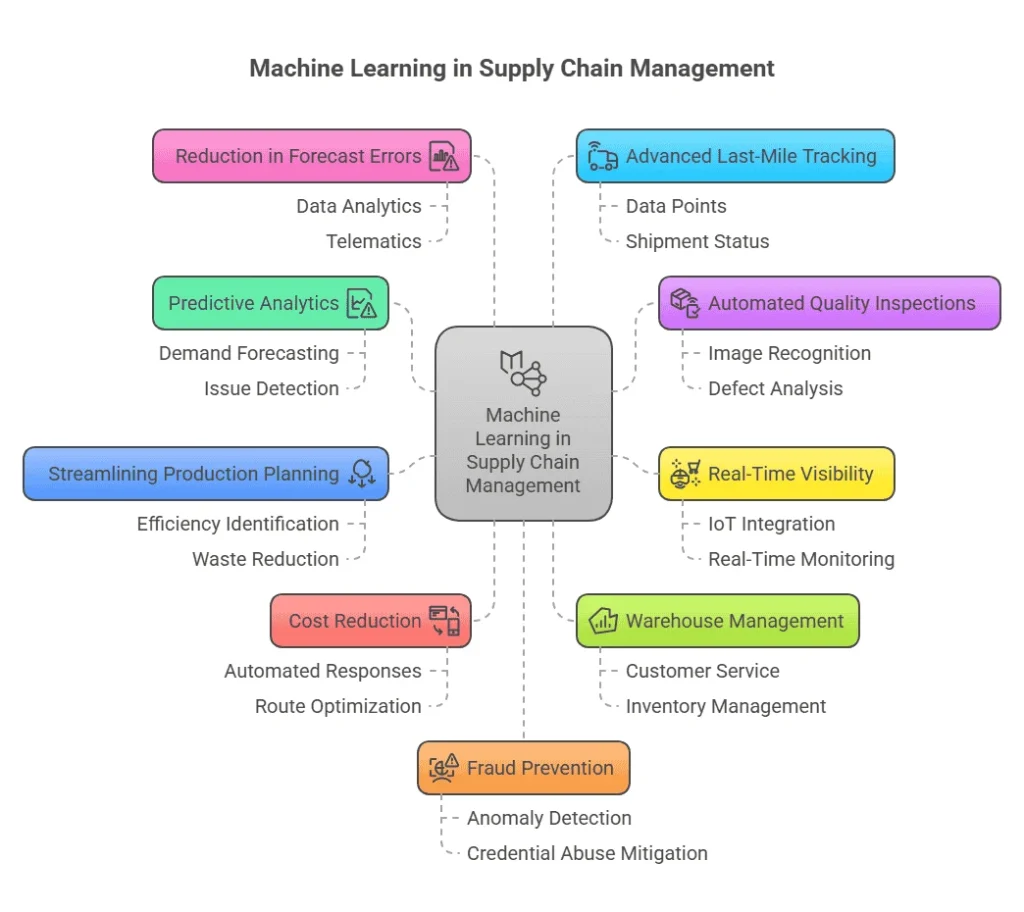

Machine Learning, a multifaceted and captivating field, offers solutions across various industries. In the heavily data-dependent domain of supply chain management, numerous applications of machine learning abound. Below, we explore nine top use cases where machine learning can drive efficiency and optimization within the industry.

1. Predictive Analytics

Accurate demand forecasting is pivotal in supply chain management, enabling reduced holding costs and optimal inventory levels. Machine learning models excel at predictive analytics for demand forecasting, identifying hidden patterns in historical data. These models also detect supply chain issues before they disrupt operations, equipping businesses to respond swiftly and effectively.

2. Automated Quality Inspections

The rise of artificial intelligence and machine learning has expanded the scope of automating quality inspections in logistics. Machine learning techniques facilitate automated analysis of defects and damages via image recognition, minimizing the risk of delivering faulty goods to customers.

3. Real-Time Visibility for Enhanced Customer Experience

Supply chain businesses face ongoing challenges with visibility and tracking. Machine learning techniques, coupled with IoT and real-time monitoring, substantially improve supply chain visibility, enhancing customer experience and enabling faster delivery commitments.

4. Streamlining Production Planning

Machine learning optimizes production planning complexity by training algorithms on available production data to identify inefficiencies and waste. Additionally, machine learning fosters adaptability to disruptions within the supply chain.

5. Cost Reduction and Response Time Improvement

B2C companies leverage machine learning to automate responses and address demand-to-supply imbalances, reducing costs and improving customer experience. Machine learning algorithms optimize fleet routes, minimize driving time, and enhance productivity.

6. Warehouse Management

Machine learning enhances warehouse and inventory management by continuously improving customer service levels at minimal cost. ML models and forecasting features prevent overstocking or understocking issues, transforming warehouse management practices.

7. Reduction in Forecast Errors

Machine Learning processes vast data sets, ensuring accurate forecasts through advanced analytics. Telematics, IoT devices, and intelligent transportation systems contribute to enhanced insights and reduced forecast errors, as reported by McKinsey.

8. Advanced Last-Mile Tracking

Last-mile delivery efficiency significantly impacts customer experience and overall supply chain costs. Machine learning leverages various data points to optimize delivery processes, providing clients with precise shipment status updates.

9. Fraud Prevention

Machine learning algorithms automate inspections and auditing processes, reducing the risk of fraud by detecting anomalies in real time. Additionally, these tools mitigate privileged credential abuse, a common cause of breaches across the global supply chain.

Machine Learning Techniques for Demand Forecasting

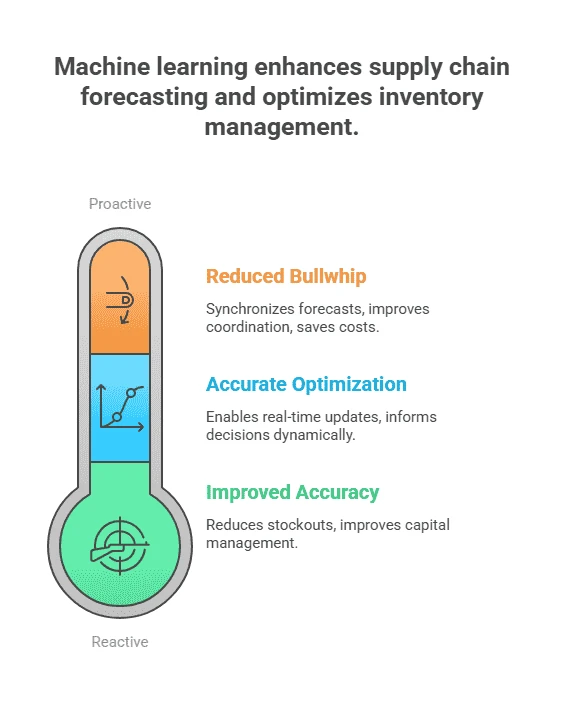

Machine learning revolutionizes supply chain forecasting by delving deep into historical data, capturing intricate patterns and relationships that traditional methods often miss. These advanced algorithms consider a plethora of variables—from sales data to social media sentiment—yielding richer insights and more precise predictions.

1. Improved Accuracy

The benefits are manifold. Enhanced forecasting accuracy mitigates risks of stockouts or excess inventory, translating into cost reduction, improved working capital management, and elevated customer service levels. By striking the optimal balance in inventory levels, businesses unlock capital for growth initiatives while ensuring products are available when customers need them.

2. Accurate Optimization

Moreover, machine learning enables real-time updates, continuously adjusting forecasts as new data streams in. This dynamic approach empowers companies to make informed decisions amidst evolving supply chain dynamics, reducing risks associated with outdated forecasts.

3. Reduced Bullwhip Effect

Additionally, machine learning curtails the notorious bullwhip effect, where demand variability amplifies up the supply chain. ML fosters improved coordination and planning by providing synchronized demand forecasts to all stakeholders, leading to substantial cost savings and smoother operations across the supply chain.

Conclusion

In conclusion, machine learning in supply chain management stands as a transformative force, revolutionizing the industry by enhancing efficiency and resilience. Through predictive analytics, automated quality inspections, and real-time visibility, ML optimizes operations, reduces costs, and elevates customer experiences.

Despite challenges, its potential to streamline production, reduce forecast errors, and prevent fraud underscores its indispensable role in modern supply chains.

As businesses seek to leverage ML for competitive advantage, Qodenext offers tailored solutions to harness the full potential of machine learning in supply chain management, ensuring sustainable growth and success in today’s dynamic business landscape.

FAQs: Machine Learning in Supply Chain Management

1. What are some disadvantages of machine learning in supply chain management?

Disadvantages of machine learning in supply chain management include the need for extensive data, potential algorithm biases, complexity in implementation, and the risk of overreliance on automation.

2. What are the 4 basic things in machine learning?

The four basic things in machine learning are supervised learning, unsupervised learning, semi-supervised learning, and reinforcement learning.

3. Is machine learning in supply chain management expensive?

Machine learning implementation in supply chain management can be expensive due to initial setup costs, data infrastructure requirements, and ongoing maintenance expenses.

4. Can machine learning reduce the time taken in supply chain management?

Machine learning can reduce the time taken in supply chain management by optimizing processes, automating repetitive tasks, and providing real-time insights for swift decision-making.

5. What is machine learning in supply chain management?

Machine learning (ML) in supply chain management means using algorithms and data to automate and improve decisions in areas like inventory management, demand forecasting, logistics, and risk management. It helps companies analyze patterns in large datasets, predict future trends, and make smarter, faster business choices.

6. How is machine learning used in logistics?

Machine learning is widely used in logistics to enhance efficiency and reliability. It helps optimize delivery routes by analyzing real-time traffic, weather, and shipment data, ensuring faster and more cost-effective deliveries. Machine learning algorithms also track shipments, predict when vehicles or equipment need maintenance, and manage inventory levels to prevent shortages or overstocking. Additionally, machine learning automates warehouse operations, improves quality control, and assists in fraud detection, making logistics operations more streamlined, secure, and customer-focused.

7. How will machine learning transform SCM?

Machine learning is poised to transform supply chain management by making processes more predictive, automated, and responsive. It enables companies to anticipate demand fluctuations, optimize inventory levels, and automate routine tasks such as order processing and warehouse operations. Machine learning also helps identify potential risks and disruptions early, allowing for proactive management. This results in reduced costs, faster delivery times, and improved service quality, giving businesses a significant competitive advantage.

8. What are the 4 types of machine learning?

The four main types of machine learning are supervised learning, unsupervised learning, semi-supervised learning, and reinforcement learning. Supervised learning involves training models on labeled data to make predictions, while unsupervised learning finds hidden patterns in unlabeled data. Semi-supervised learning uses a combination of labeled and unlabeled data for training, and reinforcement learning relies on algorithms that learn by interacting with an environment and receiving feedback in the form of rewards or penalties. Each type is suited for different tasks in supply chain management, from forecasting to process optimization.