If a company wanted to streamline its operations without any middleman then it would need vertical integration. But what is vertical integration? This type of integration allows companies to directly take ownership of various stages of their production process rather than rely on external contractors or suppliers.

So, how can a company achieve this?

Companies have achieved “vertical integration” by establishing or acquiring their suppliers, manufacturers, distributors or retail locations instead of outsourcing them. Vertical integration can be risky due to the significant initial capital investment required.

Four Degrees of Vertical Integration

To understand It, let’s see its four degrees.

- Full Vertical Integration

Obtaining all assets, resources and expertise needed to replicate the upstream or downstream member of the supply chain.

- Quasi Vertical Integration

This entails obtaining some stake in a supplier in the form of specialized investments or an equity stake to obtain agency benefits by increasing the ownership interest in the outcome.

- Long-Term Contracts

This is a diluted form of vertical integration in which some elements of procurement remain constant. This reduces inconsistencies in product delivery while holding costs constant to a certain extent.

- Spot Contracts

The point at which a firm is not vertically integrated is when the firm relies on spigot contacts to receive the immediate input necessary for its production.

So, vertical integration is necessary. But what is vertical integration’s working and procedure? To understand that, let’s see how it works in detail.

What is Vertical Integration Working Process?

Vertical integration refers to a business strategy where a company expands its role within the supply chain to gain control over multiple stages of the production or distribution process. Instead of operating solely at one point—such as manufacturing or retail—a vertically integrated company aims to manage several interconnected processes, thus reducing reliance on external entities.

For instance, a manufacturer may not just produce goods but also source raw materials directly or sell the finished products to consumers through owned retail stores. This level of integration boosts self-reliance, enhances operational control, and often leads to cost efficiencies.

Steps Involved in Vertical Integration

Vertical integration requires strategically acquiring or internalizing operations across two or more stages of the product lifecycle—from raw material procurement to final customer delivery.

Below are the key steps in the vertical integration process:

1. Control Over Raw Materials

A company begins by removing its dependency on third-party suppliers by:

- Purchasing or developing raw material sources (e.g., farms, mines, or component manufacturers).

- This leads to cost savings, supply chain consistency, and greater bargaining power.

Example: A chocolate manufacturer acquiring a cocoa farm to source its own ingredients.

2. Capturing the Production Process

The company continues by controlling or expanding its manufacturing operations, allowing for:

- Reduced production delays

- Improved quality assurance

- Customized production capabilities

Example: A fashion retailer investing in its own garment production facilities.

3. Owning Distribution Channels

To gain control over how products reach customers, companies may:

- Buy logistics providers, invest in warehousing, or establish their own distribution networks, such as delivery fleets.

- This reduces dependency on third-party logistics companies and helps optimize delivery timelines and costs.

Example: A mattress company using its own delivery vans to ensure faster, damage-free product shipments.

4. Investing in Retail or Customer Relations

The final stage involves selling directly to customers, often by:

- Launching eCommerce platforms

- Opening physical retail stores

- Managing in-house customer service teams

Example: A smartphone manufacturer opening branded retail stores and selling via its own website instead of third-party marketplaces.

Why Do Companies Choose Vertical Integration?

Companies opt for vertical integration to:

- Lower operational costs by eliminating middlemen

- Strengthen supply chain control and reliability

- Improve profit margins across various touchpoints

- Enhance product differentiation through vertical control

- Increase entry barriers for competitors

All these steps involve a substantial investment of money to set up facilities and hire additional talent and management. Vertical integration also ends up increasing the size and complexity of the company’s operations. So now that we know the “What” and the “How,” let’s talk about the “Why.” So, what are the benefits of having a vertically integrated company?

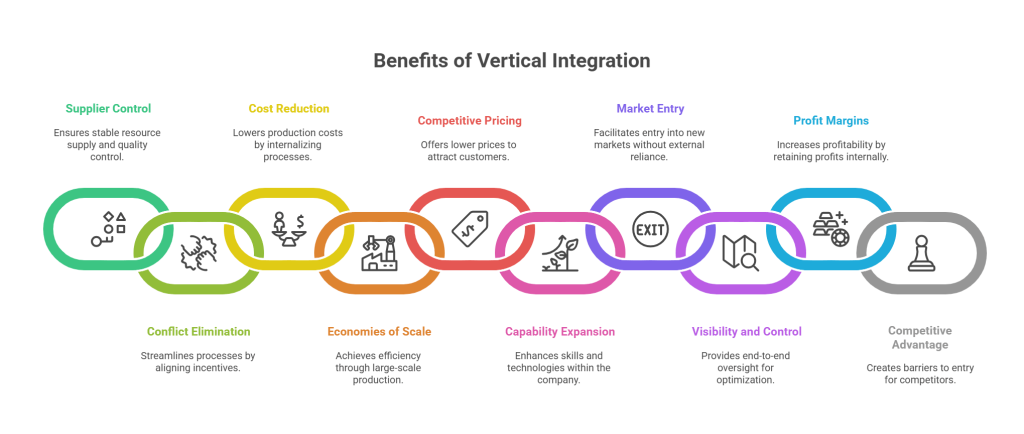

What are the Advantages of Vertical Integration

Vertical integration allows a company to gain control over multiple stages of its supply chain, from sourcing raw materials to manufacturing and selling finished products. This comprehensive strategy offers several benefits that can improve efficiency, reduce costs, and provide a strong competitive edge. Here are the main advantages, clearly explained:

1. Better Control Over Suppliers and Resource Stability

By owning or directly managing suppliers, a company gains a steady, reliable supply of key materials. This reduces dependency on external vendors, minimizes delays and disruptions, and enables better quality control throughout production. Consistency in inputs leads to more predictable outputs and allows for rapid responses to market or operational changes.

2. Eliminating Supplier Conflicts

When different parts of the supply chain are controlled by separate businesses, disagreements over pricing, quality, or delivery terms can occur, causing delays or inefficiencies. Vertical integration aligns incentives within a single organization, removing sources of conflict and streamlining the negotiation and delivery process.

3. Lower Production and Input Costs

Producing or sourcing essential inputs internally removes third-party markups and external profit margins. By internalizing costs related to materials or services, a company can manufacture products more cheaply over time. This reduction in costs allows the business to operate more efficiently and can improve overall profitability.

4. Economies of Scale

As the company grows through vertical integration, it can produce larger quantities, buy raw materials in bulk, and streamline management structures. These efficiencies lower the cost per unit of production, making each item less expensive to produce. This structure is particularly effective for businesses aiming to expand operations while maintaining cost discipline.

5. Ability to Offer More Competitive Pricing

Cost savings from efficient internal processes and bulk purchasing can be passed on to customers in the form of lower prices. With more attractive pricing, a company can strengthen its position in the marketplace, attract more customers, and build lasting brand loyalty.

6. Expansion of Capabilities and Internal Resources

By integrating new stages of the supply chain, a business gains access to new expertise, skills, and technologies. These additional resources can help improve product offerings, drive innovation, and enhance the company’s ability to meet changing market requirements.

7. Entry Into New Markets

Controlling distribution or retail channels allows a company to enter new geographical or customer markets more easily. This expansion is possible without relying on external partners, which helps the business maintain brand consistency, gather direct customer feedback, and grow revenue.

8. Complete Supply Chain Visibility and Control

Vertical integration enables end-to-end oversight of all processes, from production to sale. This visibility allows for better inventory planning, more accurate demand management, quick issue resolution, and the ability to optimize logistics for cost and speed.

9. Higher Profit Margins

Keeping more processes within the company captures profits that would otherwise go to outside suppliers, logistics providers, or retailers. Retaining these margins can lead to stronger financial performance and additional capital to reinvest in the business.

10. Stronger Competitive Advantage

A vertically integrated company can set higher barriers to entry for competitors by controlling unique assets, critical technologies, or distribution channels. This comprehensive control makes it difficult for new entrants to compete on price, speed, or customer experience, thus maintaining or growing market share.

Vertical integration, when well-executed, is a powerful strategy for businesses seeking growth, more predictable operations, and improved market position. Each advantage contributes to building a more resilient and capable organization that can better serve customers and respond to industry changes tail outlets enables faster access to consumer behavior data, facilitating agile adjustments in production and distribution to meet market demands effectively.

Conclusion

Understanding what is vertical integration as a process in supply chains, helps companies to streamline their operations. This in turn has benefits like reducing costs and gaining greater control over the supply chain.

Through implementing strategies like backward and forward integration, companies can navigate the complexities and reap benefits lіke cost reduction, enhanced demand management, and increase market share. To have guidance on this, contact Qodenext.

FAQs: What is Vertical Integration: Understanding Strategies, Process, Benefits

1. What is vertical integration?

Vertical integration is a business strategy in which a company expands its control over multiple stages of the supply chain or production process—such as sourcing raw materials, manufacturing, and distributing or selling products. This approach helps companies become more self-reliant, reduce costs, and improve efficiencies across the value chain.

2. Why do companies opt for vertical integration?

Companies pursue vertical integration to reduce dependency on external suppliers, lower production and logistics costs, maintain quality control, enhance margins, and create competitive advantages. It also allows better control over delivery times and customer experiences.

3. What are the main types of vertical integration?

There are two types:

- Forward integration – when a company controls distribution or retail (e.g., a manufacturer opening its own stores).

- Backward integration – when a company takes over its supply chain (e.g., a retailer acquiring a manufacturing facility).

4. How can companies create a vertical integration strategy?

Companies can pursue vertical integration by acquiring suppliers, investing in in-house production facilities, building distribution networks (like warehouses and delivery fleets), or launching direct-to-consumer platforms such as ecommerce websites or retail stores.

5. What industries commonly use vertical integration?

Industries such as automotive, technology, retail, oil and gas, manufacturing, and food and beverage often use vertical integration to manage rising operational complexities and improve supply chain efficiency.

6. What’s the difference between vertical and horizontal integration?

Vertical integration involves expanding control up or down the supply chain (e.g., adding suppliers or distributors). Horizontal integration refers to expanding within the same level of the supply chain, often by acquiring or merging with competitors in the same industry segment.

7. Can vertical integration reduce manufacturing costs?

Yes, by acquiring suppliers or managing in-house production, companies eliminate middlemen, streamline operations, and lower procurement costs—resulting in substantial savings on manufacturing expenses.

8. Is vertical integration suitable for small businesses?

While traditionally pursued by larger corporations, small businesses can implement vertical integration on a smaller scale—such as managing their own distribution, using direct sales platforms, or partnering with affiliated suppliers for better cost control.

9. What are the risks or challenges of vertical integration?

Vertical integration requires high capital investment, managerial complexity, and operational risks such as reduced flexibility, over-dependence on internal systems, or difficulty managing multiple processes under one organization.

10. How does vertical integration impact customer experience?

It often enhances customer experiences by improving product availability, faster delivery times, pricing control, and consistent quality. Companies that manage both production and distribution can tailor services closely to customer expectations.