Today, initiating a business may seem straightforward, yet sustaining its smooth operation and ensuring profitability poses significant challenges for most entrepreneurs. At its core, a thriving business must prioritize both the creation and sale of goods or services. Efficient management of operations and supply chain becomes paramount in addressing diverse challenges and fostering growth and success.

In this blog, we have included a comprehensive overview of the significance of supply chain and operations management in business endeavours.

Let’s get right into it!

Defining Operations and Supply Chain Management

“Operations and Supply Chain Management” (OSCM) involves managing how a company gets its materials and handles its operations. This includes tasks like buying, managing inventory, planning production, delivering products, running stores, predicting demand, processing orders, and more. It’s relevant for both making things and providing services.

The main aim of supply chain and operations management is to help companies operate better and save money by improving how they do things. Let’s now look at some of the important steps of this in the regular warehouse.

Stages in Operations and Supply Chain Management

Operations and Supply Chain Management (OSCM) integrates production (operations) with the broader flow of goods and services (supply chain). When managed well, it helps businesses meet consumer demands efficiently while maximizing profitability.

Companies like McDonald’s have mastered OSCM to deliver affordable, high-quality meals at scale. Likewise, Walmart has built its retail dominance using OSCM to optimize logistics, reduce costs, and offer competitive pricing.

Here are the key stages in OSCM:

- After-Sales Service

Handling returns, product issues, and customer support to build trust and loyalty. - Supply Chain Planning

Strategic deployment of resources to meet forecasted demand, ensuring continuity and service quality. - Sourcing

Selecting reliable suppliers who provide the goods and services necessary for production. - Production

Managing the transformation of raw materials into final products, focusing on speed, quality, and efficiency. - Delivery & Logistics

Coordinating the movement of goods to customers, ensuring timely and cost-effective distribution.

| Stage | Name | Objective | Key Activities | Real-World Example |

|---|---|---|---|---|

| 1 | Planning | Align resources with demand | Forecasting, budgeting, cross-functional coordination | McDonald’s forecasting burger sales at each location |

| 2 | Sourcing | Obtain quality inputs at best value | Supplier selection, negotiation, contract management | Apple working with Foxconn for manufacturing parts |

| 3 | Production | Convert inputs into finished goods | Manufacturing, quality control, productivity monitoring | Toyota’s lean production lines |

| 4 | Delivery | Ensure timely distribution | Warehousing, shipping, order fulfillment | Amazon’s same-day Prime deliveries |

| 5 | Service Support | Handle post-purchase needs | Returns, support calls, repairs, customer feedback | Dell’s at-home laptop servicing and returns |

Next, we will look at the advantages that it has to offer!

Operations Management vs Supply Chain Management: Key Differences

| Aspect | Operations Management | Supply Chain Management |

|---|---|---|

| Scope | Internal processes within the organization. | Entire network, including suppliers, manufacturers, distributors, and customers. |

| Focus | Optimizing internal processes, production, and service delivery. | Coordinating external and internal processes to deliver products to customers. |

| Primary Concern | Efficiency, productivity, and quality within the organization. | Flow of goods, information, and finance across the supply chain. |

| External/Internal | Internal (employees, equipment, processes). | External (suppliers, logistics, partners) and internal. |

| Customer Interaction | Indirect (supports customer satisfaction through internal efficiency). | Direct (ensures products are available when and where customers need them). |

| Time Horizon | Shorter (tactical and operational decisions). | Longer (strategic decisions, supplier relationships, network design). |

| Complexity | Managing internal resources and processes. | Managing relationships and logistics across multiple organizations. |

| Technology Use | Focuses on internal efficiency tools. | Relies on advanced platforms for sourcing, tracking, and coordination. |

Importance of Operations and Supply Chain Management

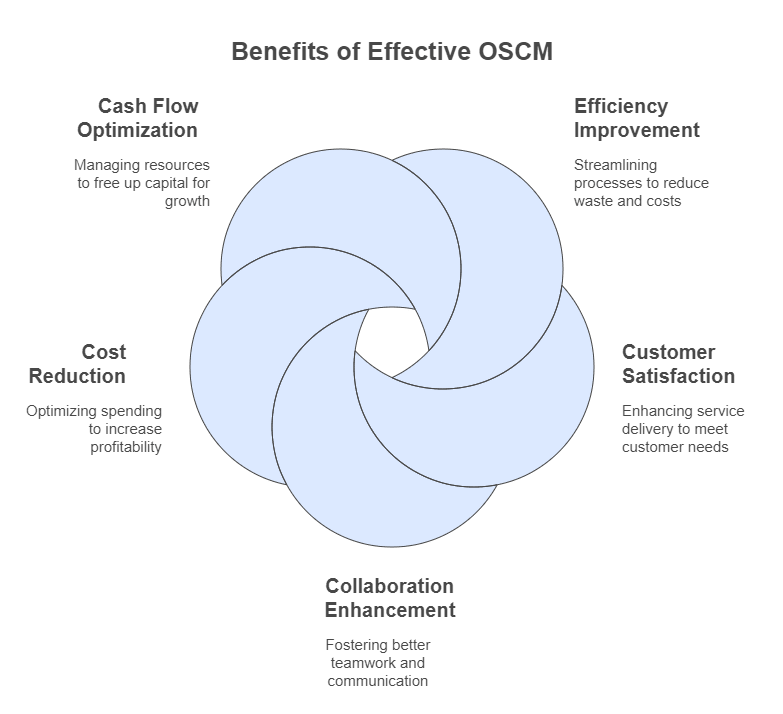

Good Operations and Supply Chain Management (OSCM) are really important for all businesses. They help plan and carry out all the things needed to make goods and services. OSCM also looks after moving resources, data, and money from suppliers to customers. Here are some big benefits of doing OSCM well:

1. Doing Things Better

When businesses organize how they work and how things get to customers, they waste less and save money.

2. Making Customers Happy

When businesses manage their work and supplies well, customers get what they want faster and better. This makes customers happy and makes them want to come back.

3. Working Together

OSCM helps different parts of a business and other companies work better together. When everyone talks and works towards the same goals, everything runs smoother.

4. Saving Money

Operations and Supply Chain Management helps businesses spend money smartly. This means they spend less on making things, which makes them more profitable.

5. Having More Money

By managing things well, businesses don’t have to keep so much money tied up in things like stock. This means they have more cash to make their business better.

In short, doing OSCM well helps businesses run smoother, keeps customers happy, makes teamwork better, saves money, and gives businesses more cash to grow. Next in our guide to easy your warehouse, look at the 5 best practices in SCM.

5 Best Trends in Operations and Supply Chain Management

1. Use Technology

Implementing technology is a key practice for enhancing Operations and Supply Chain Management (OSCM). For instance, adopting ERP software can optimize supply chain processes.

However, it’s crucial to assess existing procedures to pinpoint areas where technology in supply chain can bring improvement. Choosing software tailored to specific needs can provide precise reporting data for informed strategic planning and performance evaluation.

2. Strengthen Relationships with Suppliers

Establishing strong relationships with suppliers is essential. Continuous communication and collaboration are vital even after closing deals. Maintaining and enhancing these relationships through ongoing dialogue fosters mutual trust and helps resolve any issues that may arise.

3. Be Socially Responsible

Adopting environmentally responsible practices is increasingly important in OSCM. Reducing the carbon footprint not only aligns with societal expectations but also enhances efficiency and appeals to environmentally conscious customers. Embracing renewable energy sources can also cut down on supply chain and logistics costs.

4. Prioritize Customers

Prioritizing customer values is paramount. Organizational structures should prioritize meeting customer needs and expectations. Monitoring market trends and customer feedback allows businesses to adapt and cultivate lasting customer relationships.

5. Communicate and Coordinate

Improving internal communication is key to enhancing productivity. Effective transmission of information between departments ensures swift and accurate decision-making, enabling the company to operate more efficiently with confidence that all stakeholders have the necessary information to perform their roles effectively.

Future Trends in Operations and Supply Chain Management

Learning about operations and supply chain management provides professionals with the necessary skills and knowledge for success in this field. OSCM professionals play a crucial role in planning, manufacturing, and distributing goods and services, essential for the sustained success of any organization.

The industry offers abundant opportunities due to the constant demand for effective outcomes. Various aspects such as sourcing, acquisition, purchasing, and planning within manufacturing and operations create numerous avenues for OSCM professionals to explore.

Moreover, careers in OSCM extend beyond traditional industries and encompass sectors like medical, finance, education, administration, military, consultancy, aviation, entertainment, nonprofit, retail, energy, transportation, and third-party logistics.

For individuals seeking to deepen their understanding of Operations and Supply Chain Management, Michigan State University, recognized as the No. 1 for Supply Chain graduate degree programs by U.S. News & World Report, in partnership with upGrad, offers the Global Master Certificate in Integrated Supply Chain Management.

This comprehensive course provides interactive learning experiences through discussion boards, quizzes, assignments, interview preparation, career guidance, access to the MSU Canvas platform for live sessions, and more.

Conclusion

In conclusion, operations and supply chain management play pivotal roles in the success and sustainability of businesses today. From streamlining processes to enhancing customer satisfaction and reducing costs, efficient OSCM practices drive growth and competitiveness.

Embracing technological advancements, fostering strong supplier relationships, and prioritizing customer values are essential for future-proofing operations. Qodenext offers comprehensive solutions to optimize OSCM processes, empowering businesses to thrive in dynamic markets.

As we navigate evolving industry trends and challenges, investing in OSCM capabilities remains crucial for achieving operational excellence and long-term success. Let Qodenext be your partner in unlocking the full potential of your operations and supply chain management strategies.

FAQs: Operations and Supply Chain Management: Complete Guide

1. Is operations and supply chain management costly?

Operations and supply chain management can involve costs, but whether it’s costly depends on various factors such as the size of your business, the complexity of your operations, and the resources you allocate to managing them.

While implementing efficient operations and supply chain management practices may require initial investments in technology, training, and infrastructure, the long-term benefits often outweigh the costs by improving efficiency, reducing waste, and enhancing customer satisfaction.

2. Do I need to hire a team for operations?

Whether you need to hire a team for operations depends on the size and complexity of your business operations. In many cases, having a dedicated team or at least personnel responsible for overseeing operations can be beneficial.

This team can handle tasks such as planning, coordinating production processes, managing inventory, and optimizing workflow efficiency. However, the specific staffing needs will vary based on factors such as the scale of operations, industry requirements, and budget constraints.

3. How to manage logistics in a warehouse?

Managing logistics in a warehouse involves several key steps:

- Organize the warehouse layout for efficient storage and retrieval of goods.

- Implement inventory management systems to track stock levels and locations.

- Optimize picking and packing processes to minimize errors and fulfill orders quickly.

- Utilize technology such as barcode scanners and warehouse management software to streamline operations.

- Train warehouse staff on best practices for handling and moving goods safely and efficiently.

- Continuously monitor and adjust logistics processes to improve efficiency and meet customer demands.

4. How long do operations take to work?

The time it takes for operations to work effectively varies depending on factors such as the specific goals and strategies of the business, the complexity of the operations, and external factors such as market conditions and competition.

Implementing new operations management practices or supply chain improvements may require some time for planning, implementation, and adjustment before realizing significant benefits.

However, with proper planning, efficient operations can begin to show positive results relatively quickly, often within weeks or months, although continuous improvement efforts may be ongoing.

5. What is the main difference between operations management and supply chain management?

Operations management focuses on optimizing internal processes to efficiently produce goods or deliver services within an organization. In contrast, supply chain management coordinates the broader network that includes suppliers, manufacturers, distributors, and customers, ensuring the smooth flow of materials, information, and finances from raw materials to the end consumer.

6. Can operations management exist without supply chain management?

No, operations management cannot function entirely independently of supply chain management. Operations management relies on the timely and efficient delivery of materials and resources managed by supply chain processes. Both areas are interdependent and work together to ensure business success.

7. How does technology impact operations and supply chain management?

Technology plays a crucial role in both fields by automating processes, improving data accuracy, and enabling real-time tracking. Supply chain management often uses advanced platforms for global coordination, while operations management leverages technology for process optimization and quality control within the organization.

8. What skills are needed for a career in operations or supply chain management?

Key skills include analytical thinking, problem-solving, communication, project management, and familiarity with relevant software and technology. Professionals in both fields must be adept at planning, risk management, and working collaboratively with internal and external stakeholders.

9. How do operations and supply chain management contribute to customer satisfaction?

Operations management ensures that products and services are produced efficiently and meet quality standards, while supply chain management ensures that these products are available and delivered to customers on time. Together, they help meet customer expectations and build loyalty.

10. What are common challenges faced in supply chain and operations management?

Common challenges include managing inventory levels, coordinating with multiple suppliers and partners, responding to demand fluctuations, mitigating risks (such as supply disruptions), and continuously improving processes to remain competitive.