Effective inventory health management is the key to success in the fast-paced business world. Who doesn’t want to enjoy maximum profitability along with guaranteed consumer happiness with the right amount of products?

To bring this balance, it is essential to assess and know the health of your inventory. Are you searching for a reasonably simple approach to assess the health of your inventory? All of it begins with a demand-driven strategy.

Before discussing how to measure your inventory health, let us first look at customer purchasing behavior and its effects on the amount of inventory needed.

You should never forget that anticipating future customer demand (based on the quality of your service) is crucial when determining your inventory’s health.

Using helpful information from the inventory analysis metrics can increase customer happiness, enhance cash flow, and lower your business’s operating costs.

Doesn’t that sound interesting? Stay tuned to learn more!

Strategies to Measure Your Inventory Health

Let’s examine some crucial metrics that help you measure your inventory analytics.

Inventory Turnover

Using this measure, you can determine the frequency at which your inventories are sold or replaced within a given time period. If you get a high turnover ratio, inventory management has been effective. Here’s the formula for measuring inventory turnover:

Inventory Turnover =Cost of Goods Sold/Average Inventory Value

DSI or Days Sales of Inventory Health

The DSI metric helps you indicate how long it takes to sell all your current inventories. If you get a lower DSI, it suggests that you have achieved faster turnover and the management is better.

Weeks of Cover (WOC)

Using this, you can get a clear idea about the number of weeks the current inventory will last, evaluating the long-term viability and sufficiency of stock levels. In the case of handling weekly trade, this metric is essential.

If you get a lower number, it denotes a high possibility of stockouts and insufficient supply to satisfy demand, whereas a more significant value implies ample inventory.

Stock-Out-Rate

This helps you keep track of how long and frequently the stock is unavailable, which is vital for preserving customer happiness and avoiding missed sales on essential items.

Gross Margin Return on Inventory Investment

Using this, you can measure the average inventory investment to the gross margin earned to determine how profitable your inventory is.

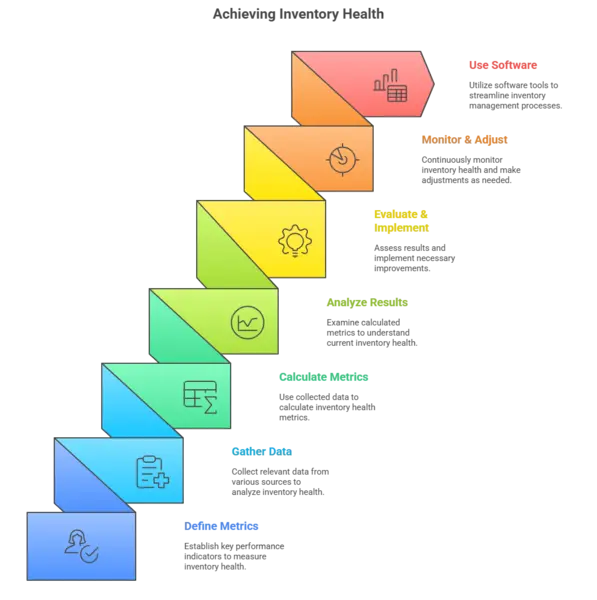

Steps to Measure Your Inventory Health

The degree to which a company’s stock levels satisfy the current consumer demand without generating waste can be termed inventory analysis. Remember that a healthy inventory always has enough items to fill every customer’s order without being overstocked and causing storage problems.

Now, let’s plunge into the steps to measure your inventory analytics.

Step 1: Determine Your Inventory Health Metrics

First, it is essential to decide which metrics you will choose based on what is relevant to your business. There are a lot of inventory health metrics- gross margin return on inventory investment (GMROI), inventory turnover ratio, ABC analysis, days sales of inventory (DSI), lead time, stockout rate, inventory accuracy, and obsolete inventory.

After determining your metrics, you need to collect data. Let’s see how.

Step 2: Collect Your Data

After deciding your metrics, you can now collect all the necessary data to calculate the respective metrics that you have chosen. Data collection involves- inventory levels, cost of goods sold (COGS), average inventory value, and sales information.

Our next step is to calculate the metrics minutely. So, there you go!

Step 3: Calculate Your Inventory Metrics

Use the data you have gathered to calculate the metrics you chose to measure your inventory health. Also, make sure that you choose the correct formulas for every metric.

Now, to understand whether your calculation is right or wrong, you need to check your results thoroughly.

Step 4: Examine Your Results

After finishing your inventory status calculation, you should examine the findings to learn more about the overall performance of your inventory. Be vigilant about recognizing developments, tracking industry trends, and areas you need to work on more to get better results.

When your results are in your hands, the next step involves evaluation and improvements. Let’s have a look!

Step 5: Evaluate & Implement Your Needs for Improvement

Based on your research, find out which aspects of your inventory management procedure require improvement. This may include- increasing your inventory turnover, lowering your stockouts or boosting your inventory accuracy, spending money on inventory software, upgrading your forecasting techniques, and so on.

After making the improvements, the next step is to keep assessing the results repeatedly and modifying things.

Step 6: Monitoring and Making Changes As Required

Try to keep a watchful eye on your inventory health metrics and make necessary modifications to your inventory management procedures. Before proceeding with the changes, you should also make sound decisions by routinely analyzing your analytics.

Can you guess the last step? Great! It is none other than using technology that makes your work easy.

Step 7: Use Software That Makes Work Easy

You can use software for managing inventory to streamline metrics calculation and gathering of data. This will help speed up your work and give you up-to-date information regarding your inventory health.

ABC Analysis: Efficient Inventory Management

ABC analysis revolutionizes how stock is managed by businesses. This is how it works:

The Three Categories:

‘A’ items High value items that require tight control

‘B’ goods: These are goods of average importance that require moderate controlDo not over manage.

‘c’ products are very faible value products but sold in a large quantities!

Key Benefits:

- Maximizes resource use

- Reduces holding costs substantially

- Avoids running out of the critical inventory item

- Allows for Data-Driven Decisions

Modern Solutions:

Today, with the help of ABC inventory software, classification is automated. The ABC inventory software delivers real-time analytics, simplifies business processes, and shines a spotlight on the most profitable items. The result? Better efficiency and greater profit across the board for all inventory types.” “And from there, on to your next job.”

Conclusion

Assessing the health of your inventory is a critical factor in the success of your business. Ongoing assessments can prevent you from making disastrous mistakes as well as increase your profitability. Follow these 7 tips to get results. Keep a close eye on your key numbers.

A healthy inventory means better cash flow and happy customers. Resource drain Don’t let your resources get drained away due to poor stock management. Act now to improve your process.

Qodenext offers businesses a powerful tool for effortless inventory management. Our system enables easy monitoring of inventory levels and facilitates forecasting for better decision-making. Bring your inventory health from reactive to proactive. Begin to measure what matters and see how much more efficient you can be. Smart inventory management starts with the right information and tools.

FAQs: 7 Ways to Measure Your Inventory Health To Plan Effectively

1. How can you measure inventory health accuracy?

It can be measured based on this formula: Inventory accuracy (counted items/items per record)x 100. By calculating this, you will get your inventory accuracy percentage.

2. What do you mean by inventory productivity?

It is the number of sales and gross profit your inventory investment gains over a specified period.

3. What are the standard metrics to calculate your inventory health productivity?

You can measure your inventory productivity using gross margin return on investment (GMROI) and inventory turnover.

4. Is inventory a key performance indicator or KPI?

Using KPI, you can determine the amount of inventory your company has presently on hand during a specific time.