Were you aware that more than 60% of eCommerce delays result from poor distribution centres? In the fast moving world of the digital market place, a disorganised distribution centre can have a devastating effect on delivery efficiency.

These hubs are the supply chain management nerve centre, enabling faster shipping, more efficient order processing, and effective consolidation of goods. If you are eCommerce retailer or logistics provider, knowing how distribution centres work is essential for growing your business.

What is A Distribution Centre?

A distribution center is a specialized logistics center that houses finished products and controls their distribution before delivery to end users. A distribution center is more than just a warehouse, in addition to storing inventory it also focuses on fulfilling orders–picking, processing and shipping them as efficiently as possible.

To put it simply, it connects suppliers, vendors, and customers by making certain that products move rapidly through the supply chain.

They are run and managed depending on the business needs and structure. For example, many companies hire third-party logistical providers to manage their multi-dimensional supply flow. Some built their operations around the centres for easy transportation and storage.

So, are warehouses different from the centres? Let’s delve into it in detail.

Warehouse vs. Distribution Centre

The spiralling eCommerce growth has led to the creation of massive storage centres in fulfilment zones. They provide hassle-free operations for businesses. Here are the major differences between a warehouse and a distribution centre.

| Warehouse | Distribution Centre |

| 1. Used as godowns to store and accumulate inventory. | 1. Used as access points to transfer goods from point of origin to end customer. |

| 2. Focus on storing items to create a sufficient buffer between supply and demand. | 2. Focus on order fulfilment. |

| 3. Located near manufacturing plants, ports, and transport routes. | 3. Strategic locations to minimise delivery time and response rate. Usually near major population centres. |

| 4. Bulk order fulfilment. | 4. Shipping to individual customers for greater redressal of delivery issues. |

| 5. Slow and steady. | 5. Agile and dynamic. |

Now, that was a great summary of warehouses and distribution centres.

Let’s understand the core functionalities of a distribution centre.

The Role of Distribution in the Supply Chain

Effectively mapping out the route from the manufacturing unit to the final destination is critical to the survival of the supply chain visibility. A modern supply network relies on transportation, distribution, and end delivery.

The role of distribution centres is to finish the fulfilment of bulk orders within a stipulated time. There is no single way to define the roles as few centres ship goods to retailers while others are experts in D2C operations. Here is a glimpse of the key roles undertaken by shipping centres.

- Picking of stock, packing, and shipping.

- Inbound freight moved to a separate dock to bypass the need for storage, thus, facilitating faster delivery.

- There are specialised distribution centres for supplier vendor management, warehousing, and inventory management.

Next, let’s understand the core benefits of distributed supply chain centres.

Advantages of Distribution Centres

There are plenty of distribution centre examples and the key benefits are listed below.

1) Cost Reduction

Last-mile deliveries are a headache for supply chain vendors; optimising the last-minute routes takes an insane amount of time. Therefore, centralising the delivery reduces the need for irrelevant storage facilities. This leads to less distance travelled, efficient time management, and fewer transit expenses.

2) Inventory Management

All companies don’t require large warehouses to store inventory as handling large volumes of items is expensive and time-consuming. A distribution centre handles the task by managing the flow of incoming orders and shipping them out on time.

3) Expertise of 3PL Vendors

Taking orders, packing boxes, and shipping are the company’s bottom-line activities. However, these tasks can be outsourced to external experts or third-party logistical companies. They have the technical knowledge to solve last-mile delivery problems in a jiffy.

Moreover, offloading the distribution load enables you to allocate more time and resources to critical business operations such as marketing, strategic planning, automation, sales, and customer service.

4) Robust Fulfilment

With customers shifting to digital buying habits, it’s imperative to meet their expectations of seamless delivery. Distribution centres offer flexibility to companies to ship thousands of orders every day. Businesses are scaling at a record pace thanks to the operational efficiency of supply chain vendors.

5) Enhanced Supply Chain Visibility

Managing logistics is challenging for a seller. A distribution centre handles all the complex processes and moving parts with ease and efficiency. From supply chain visibility, and transportation, to automated tracking, and customer redressal, these centres are capable of sorting all tasks.

Now, let’s focus on the core competencies of logistical service companies.

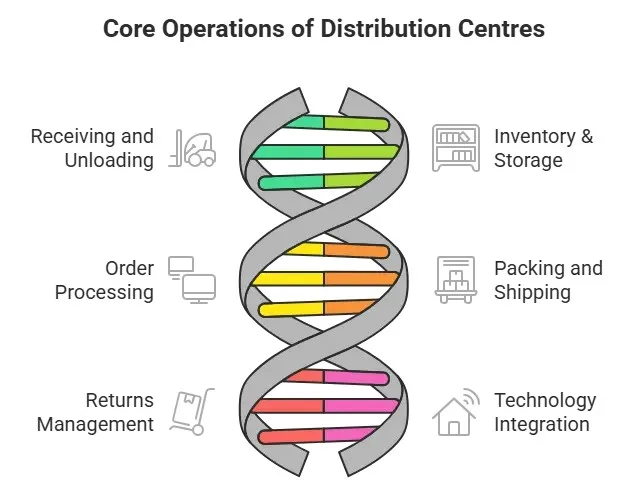

Distribution Centres – Core Operations

1) Receiving and Unloading

The first step in the operation of a distribution centre is the receiving and unloading of incoming shipments. This involves checking the accuracy of received goods against purchase orders, inspecting for damages, and recording inventory levels. Efficient receiving processes ensure that inventory is accurately accounted for, thereby making it ready for storage or further processing.

2) Inventory & Storage

After goods are received, they are promptly stored until they are ready to be shipped to customers. Inventory management is a critical aspect of distribution centre operations, involving organizing goods within the facility, tracking inventory levels in real time, and optimizing storage space utilization. Various storage systems, such as pallet racking and automated storage and retrieval systems (AS/RS), are utilized to maximize efficiency.

3) Order Processing

Order processing is a central operation, where customer orders are received, processed, and prepared for shipment. This includes picking items from inventory shelves, packing them securely, and generating shipping labels. Efficient order processing relies on streamlined workflows, accurate inventory data, and effective communication between various departments within the distribution centre.

4) Packing and Shipping

Once orders are processed, the next step is packing items into appropriate packaging materials and preparing them for shipment. The orders are packed securely to prevent damage during transit while also optimizing packaging materials to minimize shipping costs. Additionally, they coordinate with shipping carriers to schedule pickups and ensure timely delivery to customers.

5) Returns Management

Returns management is an integral part of operations, dealing with the processing and handling of returned merchandise from customers. Moreover, this involves inspecting returned items for damage, updating inventory records, and determining appropriate disposition, whether it be restocking, refurbishing, or disposing of returned goods.

An efficient returns management process is essential for maintaining customer satisfaction and optimizing inventory turnover.

6) Technology Integration

Technology includes the use of inventory management software, barcode scanning systems, and automated material handling equipment. Integration streamlines processes reduces errors, and provides real-time visibility into inventory levels and order status, enabling distribution centres to meet customer demands effectively.

Wrapping up. Let’s address the commonly asked queries for shipping service providers.

Final Message

The role of a distribution centre is to provide a hassle-free ordering experience to your customers. With the rising distribution channels and no geographical limitation, managing supply chain operations will get complex. Managing a distribution network efficiently requires the right partner. If your business is looking to optimize its distribution centre operations, reach out to Qodenext — your trusted logistics automation expert for smarter, faster fulfillment.

FAQs – Understanding Distribution Centre

1. What is a key distribution centre?

They manage shipping, transportation, and order fulfilment for eCommerce companies. These fulfillment centers play a vital role in sorting goods, managing inventory, and optimizing operational efficiency for last-mile delivery.

2. What is the role of the key distribution centre?

They offer specialised services in the delivery of goods and order fulfilment. All primary and ancillary logistic services fall under the expertise of supply chain vendors.

3. What are the two main types of distribution centres?

The major types include automated and conventional centres. It defines the percentage of material movement performed by machines, modern conveyor systems, and artificial intelligence. Human assistance is also a critical factor in the equation.

4. How Long Does Inventory Sit in a DC?

Inventory usually remains in a distribution center for a very brief period of time, ranging from days to weeks, based on the ordering pace, demand cycles, and stocking strategy.

5. What is cross-docking in DC?

In cross-docking, goods are unloaded from inbound delivery vehicles and loaded directly onto outbound ones, or combined with other goods for shipping without being stored for a long time. It makes fulfillment faster and handling fees lower.

6. What are the different technologies used in distribution centers?

Popular technologies are Warehouse Management Systems (WMS), barcode / RFID technology series, conveyors, Automated Storage & Retrieval Systems (AS/RS), robotics, predictive analytics and ERP integration.

7. What is the/process of distribution centre different from fulfillment centre?

The key difference: even though both are involved in order processing, a fulfilment centre is heavily focused on fulfilling individual customer orders (especially eCommerce), and the distribution centre tends to bulk redistribution, cross docking, and its customers are often retail and direct channels.

8. Explain the types of distribution center.

There are many types like; Automated DCs, conventional DCs, cold storage DCs, cross dock centres, and the hybrid DCs that combine B2B and D2C operations.