You might be stocking the best products in the market, but if they’re just sitting on your shelves gathering dust, your profits are quietly slipping away. That’s the crux of why inventory turnover matters.

If you’re wondering how to improve inventory management, one of the most powerful levers is optimizing your inventory turnover rate. This blog breaks it down in plain language: what inventory turnover really means, why it impacts your bottom line, and how you can boost it to improve profitability.

Let’s get started.

What is Inventory Turnover

Inventory turnover, sometimes called the stock turn ratio, measures how many times you sell and replace your inventory during a specific period.

Let’s say you sold 1,000 units this month and your average inventory was 500 units. Your inventory turnover ratio would be 2. That means you’re cycling through your inventory twice in a month.

A high turnover rate = strong sales + efficient inventory.

A low turnover rate = cash tied up + storage costs + potential waste.

Simply put, an increase in inventory turnover means you’re converting stock into sales faster, which is the goal of every business.

Now that you understand the basics, let’s look at the link between turnover and profits.

How Inventory Turnover Impacts Profitability

Here’s the truth: increasing inventory turnover rate will improve profitability. Here’s how:

- Less money tied up in stock: You invest less capital in storage and warehousing.

- Reduced carrying costs: Fewer expenses related to storage, insurance, and depreciation.

- Faster response to trends: You’re not stuck with obsolete or unsellable inventory.

- More room for high-performing products: Better stock rotation allows you to prioritize your bestsellers.

If your turnover is sluggish, it usually signals low inventory turnover—which means your products aren’t moving, and your cash flow suffers.

Alright, profitability sounds great. But how do we actually improve this metric? Let’s break it down step by step.

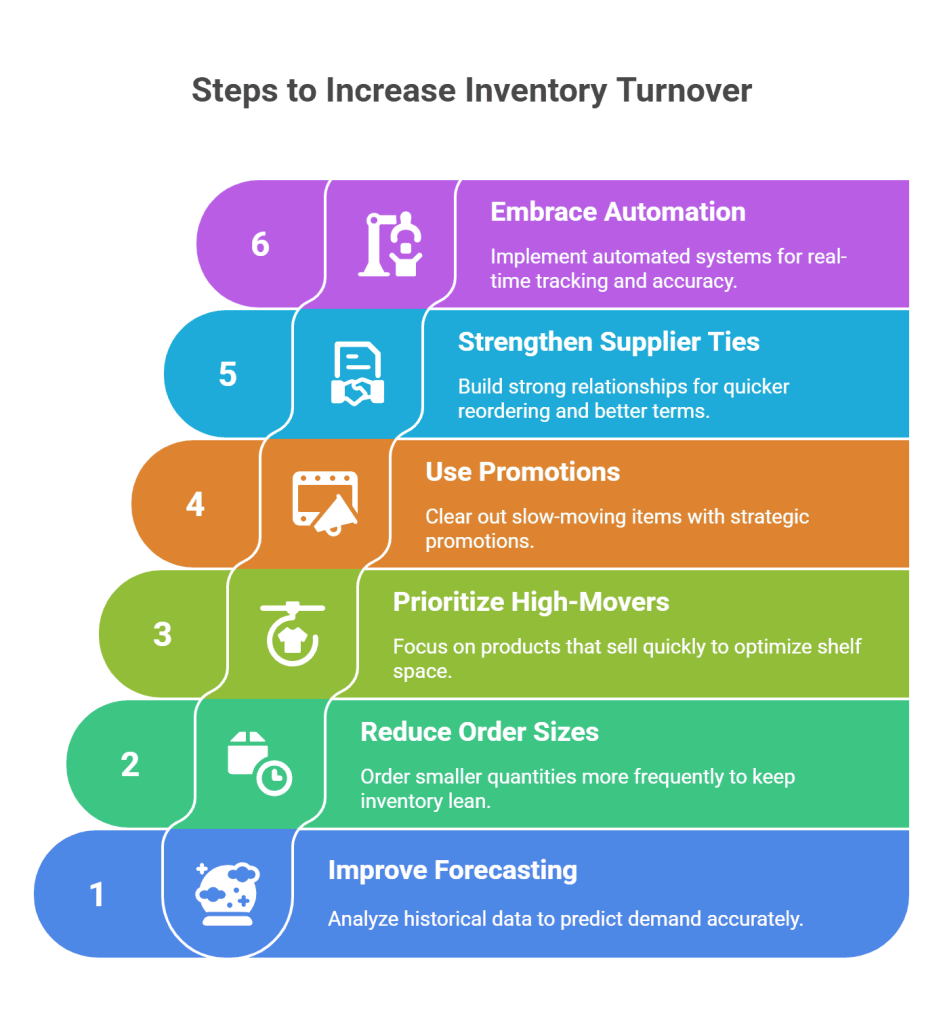

Step-by-Step Guide on How to Increase Inventory Turnover

1. Improve Demand Forecasting

If you want to know how to improve inventory management, it starts with better forecasting.

Study your historical sales data, seasonal spikes, and customer trends. Use analytics tools to get more accurate predictions.

2. Reduce Order Sizes but Increase Frequency

Smaller, more frequent orders help keep inventory levels lean and turnover high. This reduces storage costs and minimizes the risk of overstocking.

3. Prioritize High-Moving Products

Focus your inventory budget and shelf space on items that sell quickly. Use ABC analysis to identify your top-performing SKUs.

4. Use Promotions to Move Slow Inventory

Got dead stock? Run promotions, bundle offers, or clearance sales to clear it out. This helps fix low inventory turnover without total losses.

5. Work Closely with Suppliers

Strong supplier relationships allow for quicker reordering, smaller batch sizes, and better terms. That helps you react faster to demand shifts.

6. Embrace Automation and Real-Time Data

Automated inventory systems help track real-time inventory, flag slow movers, and reduce human error.

Tech = speed + accuracy

Now that you’ve got the tactics, let’s look at how to monitor your progress.

How to Measure and Monitor Inventory Turnover

Tracking your stock turn ratio helps you spot issues and track improvement. Here’s how to calculate it:

Inventory Turnover Ratio = Cost of Goods Sold (COGS) / Average Inventory

Track it monthly or quarterly. Compare it against industry benchmarks to know where you stand.

Low inventory turnover? That’s your cue to dig into problem areas.

High turnover? Time to scale what’s working.

Common Reasons for Low Inventory Turnover

Understanding the cause is the first step to fixing it. Here are some common reasons:

- Poor product-market fit (you’re stocking what customers don’t want)

- Over-ordering

- Inaccurate forecasting

- Slow-moving SKUs crowding your warehouse

- Lack of sales or marketing push

Fixing these will put you on the path of how to improve inventory turns in a sustainable way.

Now let’s zoom in on what a healthy inventory turnover rate looks like.

What’s a Good Inventory Turnover Rate?

It varies by industry. But here are rough benchmarks:

- Fashion Retail: 4–6 times/year

- Electronics: 6–8 times/year

- Groceries: 10–15 times/year

If your turnover is significantly below the norm, it’s time to figure out how to increase inventory turnover using the strategies above.

Here are some success stories that will give you a better perspective.

Zara

Zara produces in small batches and replenishes stores multiple times a week. This fast fashion model boosts turnover and minimizes overstock.

Walmart

Walmart uses real-time inventory tracking to replenish items just in time, keeping inventory lean without risking stockouts.

Amazon

With algorithms tracking purchasing behavior, Amazon minimizes storage time by turning over products at lightning speed.

FAQs : The Ultimate Guide to Improving Inventory Turnover Fast

1. Can a high inventory turnover be bad?

Yes, if it leads to stockouts or customer dissatisfaction. The key is balance.

2. Does inventory turnover affect cash flow?

Absolutely. Faster turnover frees up cash that would otherwise be stuck in unsold goods.

3. What tools help track inventory turnover?

WMS (Warehouse Management Systems), ERP software, and inventory dashboards can all help.

4. Can seasonality skew turnover ratios?

Yes. Always analyze turnover with seasonality in mind for accurate insights.

5. What’s the role of pricing in turnover?

Discounts and promotions can help improve inventory turnover by moving products faster.

Conclusion

Optimizing inventory isn’t just about counting boxes, it’s about maximizing profit.

When you figure out how to improve inventory management and crack the code on how to improve inventory turns, you free up cash, increase agility, and drive growth.

Remember that increasing inventory turnover rate will improve profitability. Whether you’re running a boutique eCommerce store or managing a multi-warehouse operation, the rules are the same.

Keep products moving, keep data accurate, and keep customers happy.