In today’s fast-paced global market, supply chains have become increasingly complex, distributed, and vulnerable to disruptions. Companies are under more pressure than ever to optimise their logistics, manage risks, and enhance transparency. This is where IoT for real-time monitoring emerges as a game-changing solution. By leveraging the Internet of Things (IoT), businesses can gain unprecedented visibility into their supply chains, enabling smarter decisions, proactive management, and streamlined operations.

This guide explores how IoT monitoring systems are revolutionising supply chain visibility and why they have become essential in modern logistics.

What Is IoT for Real-Time Monitoring?

IoT for real-time monitoring refers to the use of interconnected smart devices—like sensors, GPS trackers, RFID tags, and gateways—to collect, transmit, and analyse data from various points along the supply chain. These devices monitor critical parameters such as location, temperature, humidity, vibration, and more, feeding this information in real-time to cloud platforms or control systems.

The main goal is to allow stakeholders to track assets, shipments, or inventory continuously without manual intervention. As a result, companies can detect anomalies, prevent delays, and maintain product quality, especially for sensitive goods like food, pharmaceuticals, and electronics.

Key Components of IoT in Supply Chain Monitoring

Implementing IoT for real-time monitoring requires several interconnected elements:

1. Sensors and Actuators

These are embedded in products, containers, or vehicles to monitor environmental and physical conditions. For example, temperature sensors in a refrigerated truck ensure vaccines are transported under optimal conditions.

2. Connectivity Solutions

Data collected from sensors is transmitted through wireless technologies like Wi-Fi, 4G/5G, Bluetooth, Zigbee, or LPWAN (Low Power Wide Area Networks). The choice depends on range, bandwidth, and power requirements.

3. IoT Gateways

Gateways serve as bridges between IoT devices and cloud platforms. They aggregate data, perform edge computing functions (local analysis), and ensure secure transmission to the backend.

4. Cloud-Based Platforms

These platforms store, analyse, and visualise data from the field. They offer dashboards and alerts that help users make informed decisions in real-time.

5. AI & Machine Learning Integration

When combined with AI, IoT for real-time monitoring becomes predictive. Algorithms can forecast delays, predict equipment failures, and recommend actions before disruptions occur.

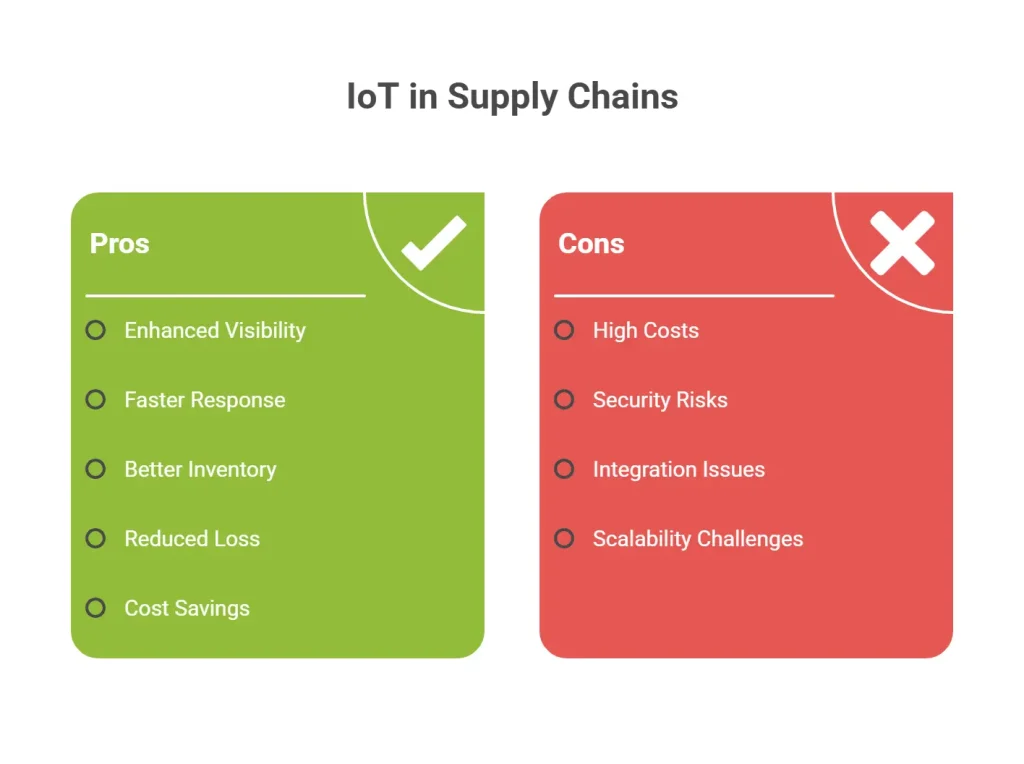

Benefits of IoT for Real-Time Monitoring in Supply Chains

1. Enhanced Supply Chain Visibility Trends

IoT devices track shipments across each leg of the journey—from warehouses to ports to retail shelves—providing end-to-end visibility. This ensures transparency across all stakeholders, including manufacturers, logistics providers, and customers.

2. Faster Response Times

By receiving real-time alerts on route deviations, cargo tampering, or equipment malfunctions, businesses can respond immediately, reducing losses and downtime.

3. Improved Inventory Management

IoT for real-time monitoring helps manage inventory dynamically. Smart shelves and RFID tags notify warehouse systems when stock levels are low, triggering automated reordering.

4. Minimised Product Loss

Perishable or fragile goods benefit immensely. IoT in industrial automation predicts temperature and moisture levels, helping preserve goods in optimal conditions.

5. Increased Efficiency and Cost Savings

Automation and accurate data eliminate the need for manual tracking and reduce human errors. Additionally, fuel usage, idle time, and maintenance costs can be optimized using data insights.

Challenges in Implementing IoT for Real-Time Monitoring

While the benefits are compelling, implementing IoT for real-time monitoring comes with its share of challenges:

1. High Initial Costs

IoT infrastructure requires investment in devices, connectivity, software platforms, and training. However, the ROI over time often outweighs the upfront costs.

2. Data Security Concerns

With millions of data points being transmitted, securing data from cyber threats is critical. Companies must adopt strong encryption, access controls, and compliance protocols.

3. Integration Complexity

Connecting IoT systems with legacy ERP, WMS, or TMS systems can be complex. Ensuring seamless interoperability is essential for effective monitoring.

4. Scalability Issues

As supply chains grow, so does the number of devices. Businesses must choose scalable platforms and ensure devices can be easily updated or replaced.

Real-World Applications

1. Cold Chain Monitoring

Pharmaceutical companies use IoT for real-time monitoring to ensure life-saving drugs and vaccines are stored and transported at required temperatures. Deviations trigger alerts that prompt corrective actions.

2. Fleet Management

Transport companies leverage IoT-enabled GPS and telematics to track vehicle routes, driver behaviour, and fuel consumption. This helps reduce delays and optimise fleet performance.

3. Warehouse Automation

Smart shelves, AGVs (Automated Guided Vehicles), and robotic arms rely on IoT sensors for efficient picking, packing, and stocking. Real-time inventory data eliminates stockouts or overstocks.

4. Port and Yard Management

In large-scale shipping, containers are equipped with IoT trackers to locate them in crowded yards. This ensures seamless customs clearance with minimal disruptions.

The Future of IoT in Supply Chain Visibility

The role of IoT for real-time monitoring will only grow as supply chains become more digitised and customer expectations increase. Here are some emerging trends:

- Edge Computing: More data processing will occur at the edge (near the data source), reducing latency and bandwidth usage.

- Blockchain Integration: Combining blockchain with IoT ensures tamper-proof shipment and transaction data records, enhancing trust.

- Digital Twins: Virtual models of supply chains will use real-time IoT data for simulations, scenario planning, and proactive decision-making.

- Sustainable Operations: IoT insights help optimise routes and reduce energy consumption, contributing to greener logistics.

FAQs on IoT for Real-Time Monitoring in Supply Chain Visibility

1. What industries benefit most from IoT monitoring?

Industries like pharmaceuticals, food and beverage, automotive, retail, and electronics benefit greatly due to their sensitivity to delays, spoilage, or theft.

2. Is IoT for real-time tracking suitable for small and medium businesses (SMBs)?

Yes. While larger enterprises have led adoption, many SMBs are now embracing the importance of IoT tracking for better control and competitive advantage.

3. How does IoT help reduce supply chain risks?

By offering real-time alerts, predictive maintenance, and route optimisation, IoT minimises disruptions, theft, spoilage, and compliance violations.

4. Can IoT be used in reverse logistics?

Absolutely. IoT devices can track returned goods, monitor conditions, and ensure proper disposal or recycling, closing the loop in circular supply chains.

5. How secure is data in IoT supply chain systems?

Security depends on the system architecture. With proper encryption, regular firmware updates, and secure APIs, IoT systems can be highly secure.

6. What challenges do businesses face when scaling IoT monitoring across supply chains?

Businesses often encounter issues with managing large numbers of devices, integrating with legacy systems, and ensuring consistent data quality and security as IoT deployments grow. Careful planning, scalable platforms, and strong IT support are essential for smooth expansion.

7. How does IoT real-time monitoring improve compliance and regulatory reporting?

IoT sensors automatically record data like temperature, movement, and delivery times, providing an auditable trail for compliance with industry standards and regulations. This automation reduces manual paperwork and ensures that critical compliance data is always available.

8. Can IoT systems provide predictive analytics for maintenance and disruptions?

Yes, when combined with AI and machine learning, IoT systems can analyze real-time and historical data to predict maintenance needs, forecast shipment delays, and proactively alert managers to potential disruptions.

9. What is the typical return on investment (ROI) for IoT supply chain monitoring?

ROI comes from reduced losses due to spoilage or theft, improved delivery accuracy, lower labor and logistics costs, and better customer satisfaction. Many companies report significant payback within 1–3 years of deploying IoT monitoring solutions.

Conclusion

IoT for real-time monitoring is a boon for modern logistics operations. With continuous data flow from the field, businesses can optimise logistics, maintain quality, enhance customer satisfaction, and future-proof operations. As technologies evolve, embracing IoT is no longer optional—it’s a strategic imperative.

Investing in IoT means investing in agility, resilience, and innovation. Whether you’re managing a cold chain, a retail distribution network, or an international logistics operation, the benefits are clear, the use cases are growing, and the time to act is now. Want to boost supply chain traceability? Contact Qodenext today.