In a land of innovation and progress, India has witnessed a remarkable rise in the embrace of automation across diverse sectors. With over 60% of businesses casting their spells of automation, the transformation has been nothing short of magical. From bustling cities to serene villages, the enchantment of automation has touched every corner of the country, weaving a tapestry of efficiency and brilliance. But fear not, dear reader! We won’t just skim the surface of this enchanting realm; we’ll dive deep into the different types of automation to unravel their mysteries and unveil the captivating stories behind them.

Automating for Progress: Different Types of Automation

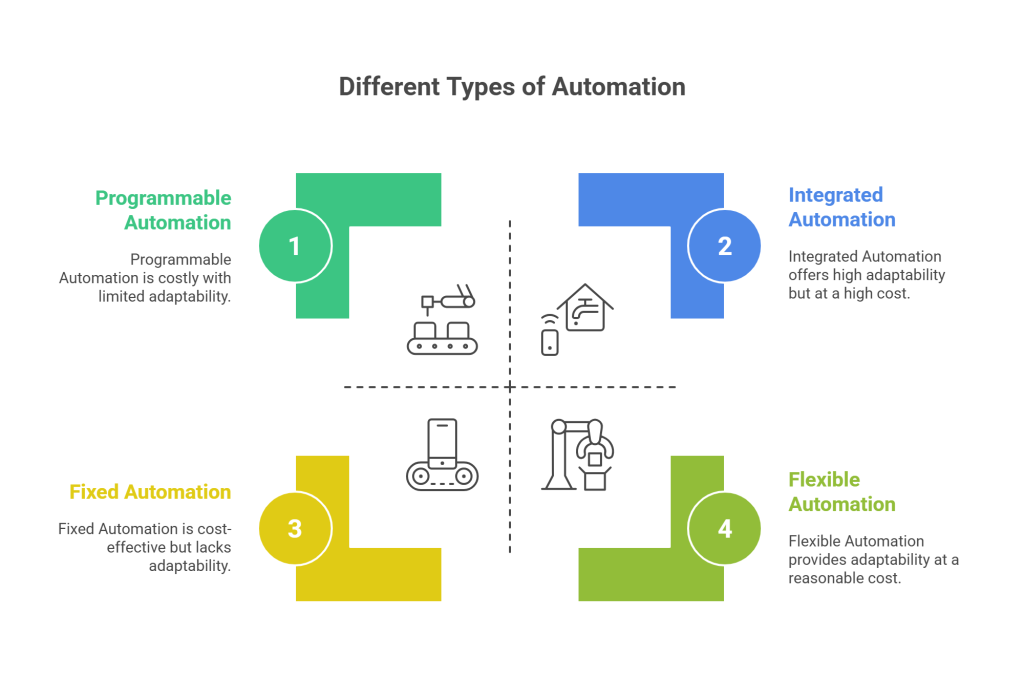

Automation comes in various flavours, each designed to cater to specific operational needs and industries. Let’s take a closer look at the four primary types of automation: programmable, fixed, flexible, and integrated.

1. Programmable Automation

Picture a bustling factory floor, where robots move with precision and efficiency, assembling products seamlessly. This scene is a testament to programmable automation’s power. In this setup, machines follow a pre-set sequence of instructions, making it ideal for processes with a fixed pattern of steps. Mass production scenarios, like those in the automotive industry, benefit greatly from this type of automation. The machines can replicate tasks with consistent accuracy, resulting in increased efficiency and improved product quality.

However, entering the realm of programmable automation demands a considerable upfront investment. Skilled technicians are needed to design, program, and maintain these systems. Despite these challenges, the long-term benefits often outweigh the initial costs, especially in industries where precision and repeatability are paramount.

2. Fixed Automation

Imagine an assembly line producing smartphones. Each step, from attaching components to quality checks, is performed with unparalleled precision. Fixed automation thrives in such scenarios. It involves specialised machinery designed to execute a specific task with exceptional accuracy and speed. These machines are finely tuned to carry out their designated functions with minimal variation.

Fixed automation is particularly beneficial in processes that demand consistent outcomes, such as in electronics manufacturing. However, the drawback lies in its lack of adaptability. Once the equipment is set up for a specific task, altering the process can be complex and costly. Therefore, industries that opt for fixed automation need stable demand patterns and well-defined processes to maximise its advantages.

3. Flexible Automation

Flexible automation involves integrating technology and machinery to achieve adaptable production processes. Unlike fixed automation, it uses robotics, sensors, and computer systems to quickly switch between tasks and respond to changing demands. This approach benefits industries requiring customization and quick adaptations.

The main advantage of flexible automation is its ability to enhance productivity while maintaining adaptability. Manufacturers can reconfigure production lines easily, reducing downtime and costs. This agility enables efficient production of a wider range of products without compromising quality. Additionally, flexible automation reduces waste, improves resource utilisation, and helps companies stay competitive in evolving industries.

4. Integrated Automation

Imagine a smart home, where lights, security, and entertainment systems are seamlessly connected and controllable through a single device. Integrated automation involves linking various processes and systems into a cohesive unit, enhancing communication, data sharing, and overall efficiency.

This type of automation is prevalent in sectors like manufacturing and supply chain management, where coordination between different processes is essential. However, achieving integration can be complex, demanding an in-depth understanding of various technologies and systems.

Benefits of Automation

Automation isn’t merely about machines; it’s a catalyst for change, enhancing processes and elevating lives.

Here are some of its key advantages:

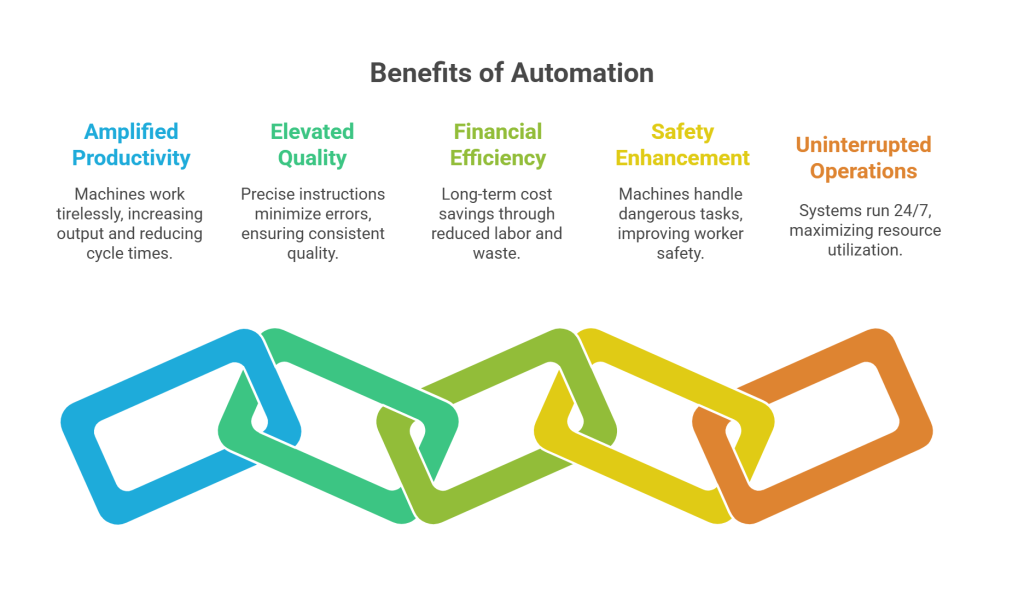

1. Amplified Productivity:

Unlike humans, machines don’t tire. This translates into increased production output and shorter cycle times. With automated systems tirelessly performing tasks without breaks, productivity reaches new heights, contributing to higher production volumes and faster project completion.

2. Elevated Quality:

Automation follows precise instructions, minimising human errors and ensuring consistent quality in output. In industries where precision is critical, like pharmaceutical manufacturing, automation drastically reduces the chances of errors caused by human factors, resulting in products of superior quality.

3. Financial Efficiency:

While the initial setup cost might be high, automation often leads to reduced labour costs and minimise waste over time. Although the upfront investment for implementing automated systems can be significant, the long-term financial gains from decreased labour expenses, lower error rates, and optimised resource utilization make it a cost-effective solution.

4. Safety Enhancement:

Dangerous tasks can be delegated to machines, mitigating workplace accidents and improving worker safety. Industries involving hazardous environments, such as chemical processing plants, benefit immensely as automation removes human operators from risky situations, ensuring both employee well-being and operational continuity.

5. Uninterrupted Operations:

Automated systems can run 24/7, maximising resource utilization and output efficiency. Unlike human workers who need rest and shift rotations, automated operations can continue without interruption, leading to efficient resource utilization and a consistent output around the clock.

Navigating the Challenges: The Cons of Automation

While automation offers significant benefits, it’s important to consider the potential challenges:

1. High Initial Investment:

Implementing automated systems requires a significant upfront financial commitment for equipment, training, and setup. However, this initial investment often leads to long-term cost savings and efficiency gains.

2. Skill Dependency:

Automation increases the demand for skilled technicians proficient in managing and maintaining these advanced systems. Companies must invest in training and upskilling to bridge the skills gap.

3. Flexibility Limitation:

Fixed automation’s lack of adaptability can be problematic for industries with changing processes or product lines. Businesses must carefully assess their needs before committing to this type of automation.

4. Technical Complexity:

Integrating diverse automation systems demands specialised expertise due to the intricacies of hardware, software, and data integration. Collaboration between different technical teams becomes essential.

5. Job Displacement:

While boosting efficiency, automation can lead to job losses in labor-intensive industries, necessitating a careful balance between technology and workforce well-being. Governments and industries should explore measures to mitigate potential negative impacts on employment.

Conclusion

To put it in brief, automation’s diverse types have revolutionized industries, promising a more efficient and precise world. Whether it’s fixed automation’s rhythmic dance on factory floors or integrated automation’s seamless smart home experience, automation is shaping our future. As we stand at this threshold, Qodenext stands as your partner. With cutting-edge solutions tailored for startups and established industries, Qodenext is your guide to embracing automation’s transformative power. Explore with Qodnext and unlock efficiency, innovation, and growth in this automated era.

FAQs: Types of Automation

1. Is automation only relevant for large-scale industries?

No, automation is beneficial for businesses of all sizes. While large enterprises may implement full-scale automation systems, small and medium-sized businesses can adopt automation in specific areas like inventory, billing, or customer service to improve efficiency and reduce manual workload.

2. What skills are needed to operate automated equipment?

Operating automated systems typically requires technical knowledge in programming, system maintenance, and troubleshooting. Basic understanding of machinery, software interfaces, and safety protocols is important, and companies often provide specialized training to upskill their workforce.

3. Can automation lead to job loss?

Automation can replace repetitive manual tasks, which may reduce certain job roles. However, it also creates new opportunities in areas such as robotics, IT support, and system analysis. Over time, automation can empower businesses to grow, leading to the creation of different types of jobs.

4. Is automation cost-effective for startups?

Although the initial investment can be high, automation can be cost-effective for startups in the long run by improving accuracy, reducing labor costs, and optimizing operations. Scalable, task-specific automation solutions can offer a good return even with a limited budget.

5. What are the main differences between fixed and flexible automation?

Fixed automation is designed for high-volume production of standardized items and lacks adaptability, making it suitable for industries like automotive or electronics. Flexible automation, on the other hand, allows quick changes in processes or products, making it ideal for businesses that require customization.

6. How does integrated automation benefit operations?

Integrated automation connects various systems and processes for seamless data sharing and communication. It improves decision-making, reduces manual intervention, and enhances overall productivity by ensuring that different departments and machines work in harmony.

7. In which industries is fixed automation most commonly used?

Industries such as automotive, electronics, consumer goods, and chemicals rely heavily on fixed automation due to their need for mass production, consistency, and high-speed operations with minimal variation.

8. How does flexible automation affect customization?

Flexible automation enables easy reconfiguration of processes, allowing manufacturers to produce varied or custom-made products efficiently. This adaptability reduces downtime and supports faster response to shifting customer or market demands.

9. What challenges do businesses face when implementing automation?

Automation involves high upfront costs, technical complexity, the need for skilled labor, and resistance to change. Organizations must plan carefully by training employees, choosing the right technology, and managing transition strategies effectively.

10. How does automation improve workplace safety?

Automation reduces human exposure to hazardous tasks or environments, lowering the risk of accidents. It is particularly useful in industries like mining, chemical processing, and manufacturing, where it enhances safety while maintaining operational efficiency.