If you still think AI is just futuristic, take a walk through a modern manufacturing floor. You might see robotic arms assembling with incredible precision.

But beyond the heavy lifting, AI is quietly playing another game-changing role: ensuring that every product rolling off the line meets the highest quality standards.

Let’s break down how AI in quality control is changing the way we inspect, analyze, and improve quality in manufacturing, with real-world examples, practical tips, and not a single ounce of tech jargon overload.

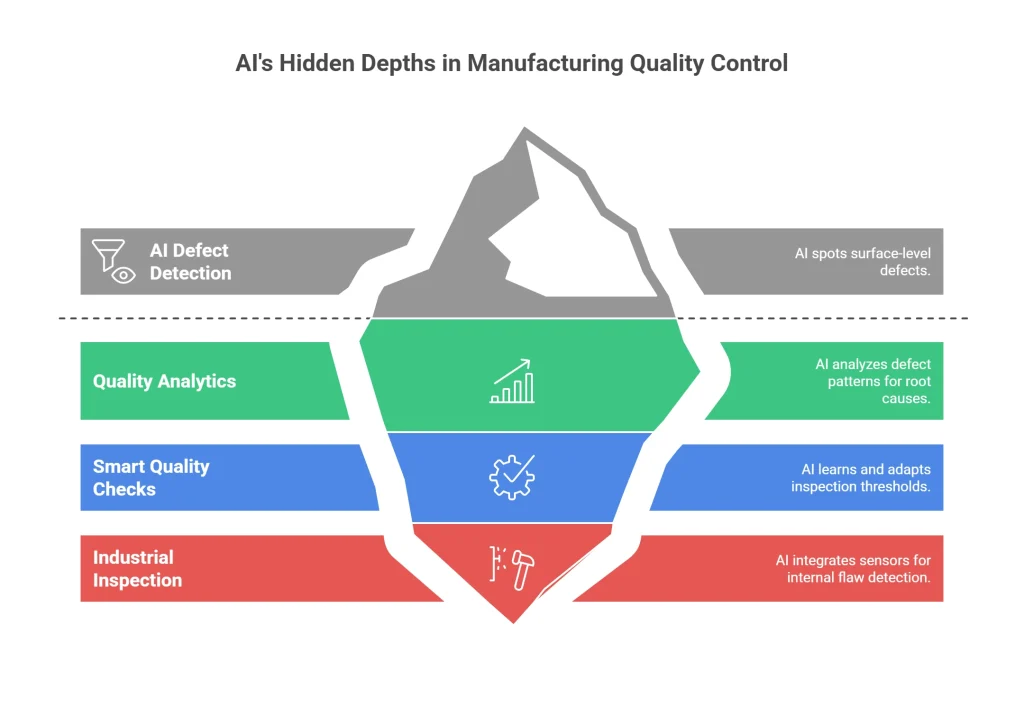

1. AI Defect Detection: Spotting the Unseen

Traditional quality control relied on human inspectors. But even the most trained eyes get tired, distracted, or miss micro-defects. Enter AI defect detection.

AI systems use computer vision and deep learning algorithms to scan products in real time. Unlike manual inspection, AI doesn’t blink. It can detect:

- Surface cracks, dents, or scratches

- Slight color deviations

- Pattern inconsistencies

- Sub-millimeter misalignments

Example in action: Samsung uses AI-powered inspection systems to detect even the most minute cosmetic issues in smartphone assembly lines. The AI learns what a perfect product looks like and flags even the slightest variations.

Now that we’ve explored AI’s sharp eyes, let’s move on to its brain and how it analyzes patterns.

2. Manufacturing Quality Analytics – Turning Data into Action

Imagine catching a quality issue not at the end of the line, but before it even happens. That’s the promise of manufacturing quality analytics.

AI can:

- Analyze patterns in defect data

- Identify root causes using production parameters

- Predict potential failures based on historical trends

- Offer suggestions to optimize settings or processes

This is like having a Six Sigma black belt working 24/7, except it’s AI.

Example in action: Boeing implemented predictive analytics to identify anomalies in aircraft component production. This reduced rework costs and significantly improved first-time quality.

Having seen how data becomes a superpower with AI, let’s move into how these systems become smarter over time.

3. Smart Manufacturing Quality Checks

AI doesn’t just make decisions; it learns. Over time, it gets better at understanding what constitutes a defect and what doesn’t.

This leads to smart manufacturing quality checks that improve with every data point.

With AI, your quality control evolves from being reactive to adaptive.

Here’s how:

- It continuously learns from operator feedback and new defect types

- Adjusts inspection thresholds based on material variations

- Adapts to seasonal changes in environmental conditions (like humidity)

Example in action: BMW’s Munich plant uses machine learning to adapt its paint inspection processes. The system learns how paint behaves under different lighting and humidity conditions, minimizing false rejections.

Now that we’ve seen AI’s ability to evolve, let’s explore how it’s being deployed practically across lines.

4. AI for Industrial Inspection: Beyond the Visual

AI for industrial inspection isn’t limited to surface-level defects. It also integrates with sensors, X-rays, ultrasound, and even thermal imaging to:

- Inspect internal flaws

- Detect anomalies in mechanical behavior

- Monitor vibrations and heat

This is especially important in industries like aerospace, pharma, or automotive where hidden defects can be catastrophic.

Example in action: GE uses AI to analyze X-ray images of turbine blades. The AI detects internal micro-fractures that even skilled technicians can miss, improving safety and reducing downtime.

Having explored how AI manufacturing solutions extend beyond vision, let’s look at why AI-driven quality is not a replacement for humans but an upgrade.

Why AI Works Best With Humans

Think of AI not as a job-taker but as a co-pilot. While AI handles high-volume inspections and analytics, humans are still key in:

- Training the AI models

- Making judgment calls in ambiguous cases

- Improving and revalidating inspection strategies

The future of AI manufacturing solutions is about augmentation, not replacement.

Now that we know the main benefits, what should you keep in mind when implementing it?

Things to Consider Before You Adopt AI

- Start small: Pick a high-defect area and test AI there first

- Train your staff: Human-AI collaboration works only when the workforce understands how the systems work

- Data quality matters: Garbage in, garbage out. Feed the AI good, clean data.

- Scale smartly: Once the AI model proves itself, expand it across lines

FAQs : Don’t Ignore These 4 AI Innovations in Manufacturing Quality Checks

1. Can AI completely replace manual quality inspection?

Not yet. AI enhances speed and accuracy, but nuanced human judgment still plays a vital role, especially in new or complex defect types.

2. Is AI suitable for small manufacturers?

Yes. Many AI manufacturing solutions are now affordable and scalable for smaller operations, especially cloud-based vision systems.

3. What kind of data does AI need for quality analytics?

It depends. Visual inspection systems need thousands of defect and non-defect images. For predictive analytics, sensor and production data are key.

4. How does AI improve the speed of quality inspections compared to manual processes?

AI systems can process and analyze product images or sensor data in milliseconds, far faster than human inspectors. This enables real-time defect detection and immediate corrective actions, reducing bottlenecks and speeding up production cycles.

5. What types of AI technologies are commonly used in manufacturing quality control?

Common AI technologies include computer vision for visual inspections, machine learning for predictive analytics, natural language processing for analyzing maintenance logs, and sensor fusion techniques that combine data from multiple sources like thermal cameras or ultrasound.

6. Can AI help in reducing waste and rework in manufacturing?

Yes, by detecting defects early and predicting potential failures before they occur, AI helps avoid producing faulty products or scrapping materials. This leads to significant reductions in waste, lower rework costs, and improved sustainability.

7. What challenges do manufacturers face when implementing AI quality control?

Key challenges include collecting and labeling vast amounts of quality data, ensuring data quality, integrating AI systems with existing manufacturing infrastructure, managing change in workforce roles, and budget constraints for initial technology investments.

8. How can manufacturers ensure ongoing accuracy of AI models?

AI models require continuous training with updated data, including new types of defects or changes in materials and processes. Regular validation, incorporating operator feedback, and periodic model retraining help maintain high accuracy and adaptability.

Conclusion

AI in quality control is more than a technology trend. It’s a shift in mindset – from checking quality at the end to building it into every stage of the process.

Whether it’s spotting a hairline crack or predicting a machine failure, AI helps manufacturers move faster, reduce waste, and deliver consistently higher quality. And as the tech gets smarter, the factories do too.

AI might not wear a hard hat, but it’s fast becoming the most valuable worker on the floor.