AUTOMOTIVE

Optimizing Component Picking with Barcode-Based Automation

Publish March 29, 2025

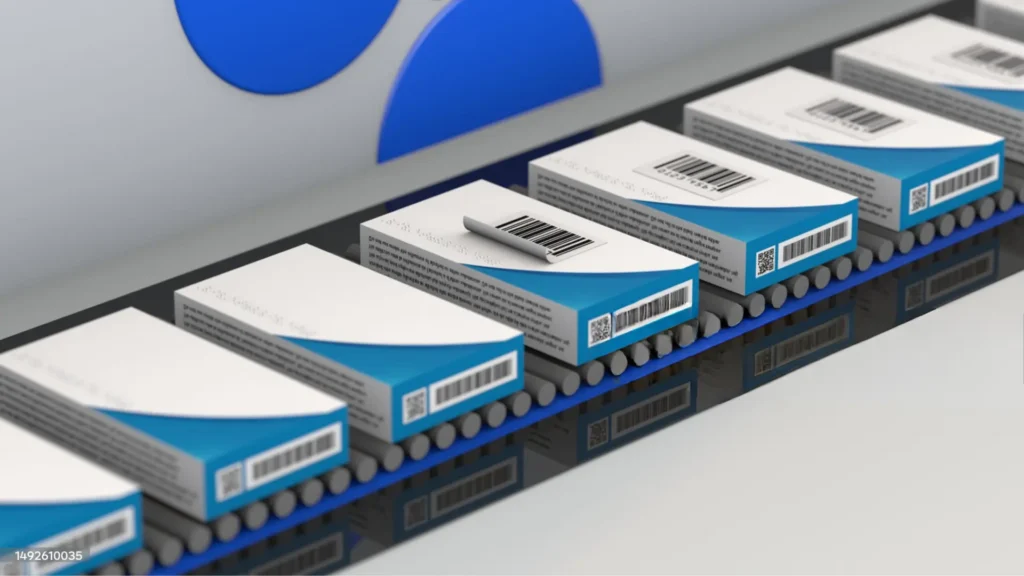

The client, a leading automotive manufacturer, faced manual inefficiencies in component picking, leading to sorting errors and production delays. QodeNext’s Pick & Place Solution introduced barcode-based tracking, intelligent location mapping, and automated picklist generation, ensuring accurate component retrieval, reduced errors, and improved efficiency. With real-time tracking and automated reporting, the solution streamlined warehouse operations, minimized delays, and enhanced resource utilization. Additionally, the integration of handheld terminals (HHT) enabled seamless validation of picking processes, reducing reliance on manual intervention and improving overall workflow accuracy.

Related Articles