AUTOMOTIVE

Enhancing Manufacturing Efficiency with WIP Barcode Automation

Publish March 29, 2025

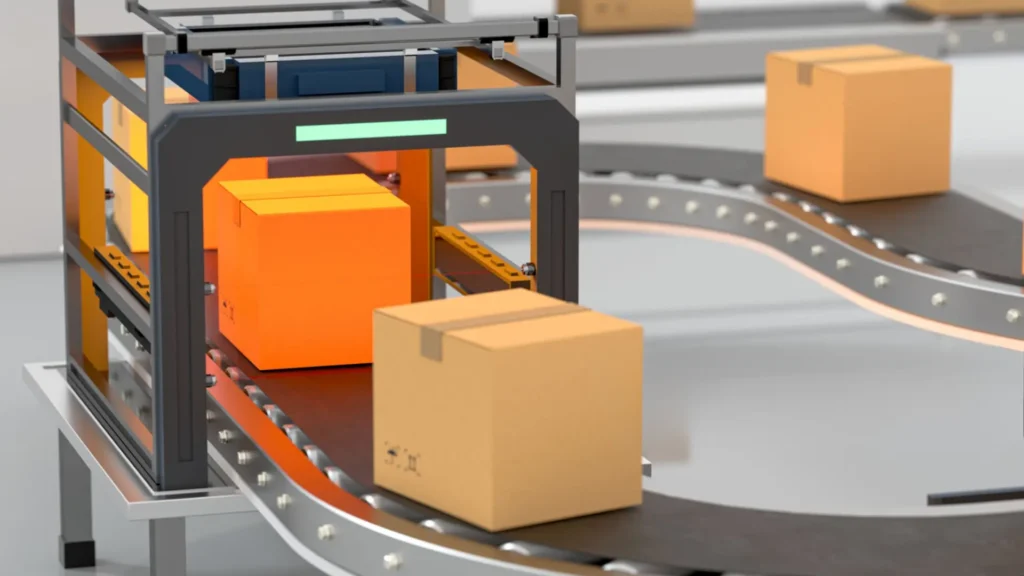

A leading global lubricants producer faced challenges with manual data capture, resulting in delays and the unavailability of real-time tracking for daily operations. To address this, QodeNext implemented a Work-In-Progress (WIP) barcode solution that ensures seamless tracking of finished goods, including barrels, pails, and cartons, from manufacturing to dispatch. The solution involves automated barcode generation for each product, with fixed mount scanners and handheld terminals capturing real-time data. By integrating directly with SAP, the system updates information instantly, eliminating manual errors and improving operational efficiency.

Related Articles