The 2025 business environment is globalized and more complicated than ever before. Those companies that have managed to achieve success in this competitive arena are those that have perfected fast and efficient delivery of products by means of effective logistics and supply chain management. It is a must-have knowledge to succeed in the modern economy, regardless of being a businessperson, a budding careerist or a curious student.

Understanding the Basics

Logistics and Supply Chain Management: What It Is?

In essence, logistics and supply chain management essentially refers to the entire mechanism of planning, executing and controlling the process of movement of goods, services and information, between the origin and point of consumption. This is a complicated process that ensures that goods reach the customers when the right moment comes, in the right condition and at the right price.

Think about it as the basis of international trade. Every single product you have ever purchased such as your daily coffee or your smartphone has gone through different stages of planning, warehousing, transportation, and delivery. It is the behind the scenes heroes that make our economy hum and they are the specialists who run these operations.

The Building Blocks contains 4000 pages of paper, 1500 of which should be opened by the reader, while the remaining 2500 pages remain unread and should be regarded as achieved knowledge.<|human|>Unpacking the Building Blocks Building Blocks have 4000 pages of paper, 1500 of which are supposed to be opened by the reader, and 2500 of which are not to be read and can be considered achieved knowledge.

There are several major elements of logistics and supply chain management:

Procurement and sourcing: The process of buying and acquiring raw materials or products with the suppliers.

Inventory management: The right level of inventory to meet demand without wastage.

Warehousing: Keeping the products safely and efficiently till the time when they are to be shipped.

Transportation: The process of moving products in and out of their destinations by means and mediums.

Order fulfillment: Proper and prompt order processing of customers.

Information systems: The data are monitored and managed throughout the process.

Customer service: Delivering satisfaction in all the touch points.

The most important difference between Logistics and Supply Chain Management

Difference between supply chain management and logistics management

The two terms are used interchangeably by most professionals, yet strategic planning is the one that a person should be able to distinguish between logistics and supply chain management.

The more general concept is the supply chain management. It is the general strategy of the whole process of extracting raw materials until the end product is delivered and even the reverse logistics.

Supply chain management involves:

Strategic supplier relationships.

Product design and development.

Demand planning

Financial planning

Risk management across the network.

Sustainability initiatives

Building partnerships in the long term.

A sub-class of supply chain management is logistics. The art of logistics is concerned with the strategy of delivering and keeping the products.

Logistics has the responsibility to:

Day to day transportation processes.

Warehouse floor operations

Route optimization

Packaging and labeling

Last-mile delivery

Returns processing

A Practical Example

Take a smartphone company. The supply chain management department is the one that determines the source of parts in five countries, quality standards, contract and seasonal changes in demand. They’re thinking in years.

These plans are then implemented by the logistics team which helps the shipments, warehouse space, route optimization, and delivery of the products to retail locations on the launch day. They are dreaming of days and weeks to come.

Difference between Logistics and Supply Chain Management.

The difference between the supply chain management and the logistics management is also limited to the scope and perspective. Supply chain management has a broad, strategic view of the entire supplier network, manufacture network, distributor network, and retailer network. It is all about developing competitive advantages by collaborating, being innovative and efficient.

The management of logistics is more operational. It is aimed at cost minimization, efficiency and flawless performance of the physical flow of goods. Supply chain managers would ask themselves, What should we do? whilst the logistics managers would ask themselves, How do we do it best?

The Future of Logistics and Supply Chain Management in 2025.

There is a radical change in the industry that has taken place over the past years. The current state of logistics and supply chain management is characterized by the rapid technological advancement and the change in the consumer behavior.

Technology-Driven Transformation

Machine Learning and Artificial Intelligence.

Algorithms powered by AI are now able to predict demand with disturbingly accuracy, plan routes in real-time and locate possible disruptions before they occur. Systems that are based on machine learning use millions of data points to make decisions within seconds, which would take people hours or days.

Internet of Things (IoT)

The sensors that are connected keep track of the shipments on transit keeping track of the temperature, humidity, location, and handling conditions. Real-time visibility allows companies to respond in real-time to issues that arise and prevents losses and product integrity.

Blockchain Technology

DLDT results in auditable and immutable records of every move and transaction in the supply chain. Traceability is being revolutionized by blockchain technology, particularly in industries where authenticity matters e.g. pharmaceuticals and luxury consumer products.

Automation and Robotics

The use of autonomous robots in warehouses now works hand in hand with human workers and has significantly increased efficiency. Pallets are moved by automated guided vehicles (AGVs) and merchandise are picked and packed by robotic arms which are extremely fast and precise.

Sustainability Becomes Non-Negotiable.

Green supply chain management and the latest logistics cannot but confront the problem of the environment. Firms are instituting:

Delivery vehicles that are electric and hybrid.

Warehouses that are powered by renewable energy.

Waste minimization strategies using the circular economy.

Footprint tracking and reduction of carbon.

Green packaging technologies.

Ethical sourcing specifications.

The buying choice of consumers is more and more driven by the environmental behavior of the company, turning green logistics into the competitive nature and not the additional benefit of the company.

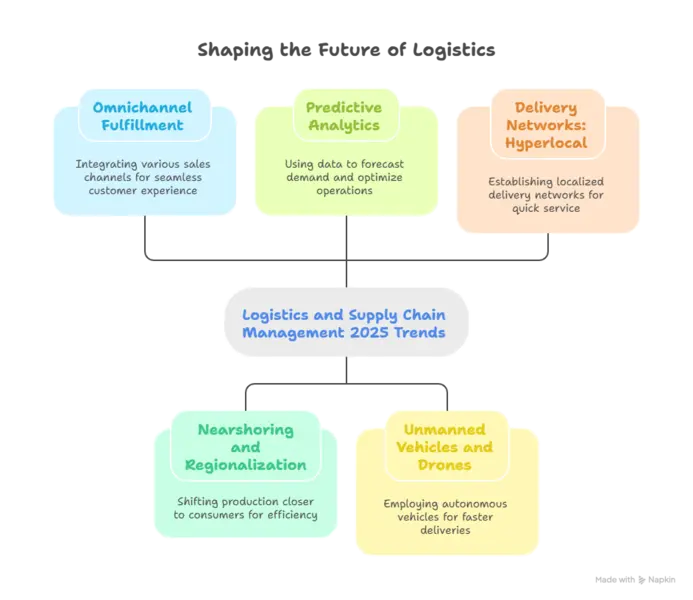

Critical Logistics and Supply Chain Management 2025 Trends

Omnichannel Fulfillment

Frictionless experiences among customers are desired in online shopping, stores and mobile applications. The executives of logistics and supply chain management must coordinate:

Buy online, pick in store (BOPIS).

Ship to store functionality.

Availability of same-day delivery.

Basic cross-channel returns.

Constant inventory visibility.

Nearshoring and Regionalization.

The disruptions in the world have taught companies that supply chains are extremely important. To reduce lead times and global disruption exposure, companies are moving to near end markets.

Predictive Analytics

Complicated analytics systems anticipate all the demand peaks to potential supplier issues. High-precision analytics software helps companies to be active rather than responsive in the sense that they do not face a stockout or overstocking situation.

The Unmanned Vehicles and Drones.

In some markets, last-mile deliveries are being undertaken by autonomous delivery vehicles and drones as they continue to be developed. The technology will save a lot of money and will accelerate the delivery pace to a great extent.

Delivery Networks: Hyperlocal.

Ultra-fast delivery is made possible by dark stores and micro-fulfillment centers which are situated in urban areas. These are facilities that are specialized in online orders, delivery of products to customers within less than an hour.

Career development in Logistics and Supply Chain Management.

The field offers complicated and diverse career opportunities to all professionals.

In-Demand Jobs

Supply Chain Analyst:

Uses facts to facilitate operation and find possible improvement points.

Procurement Manager:

negotiates with suppliers and buys supplies.

Warehouse Operations Manager:

Oversees operation and personnel management of the facilities.

Transportation Coordinator:

Preparation and coordination of strategies of shipping.

Demand Planner:

Forecasts the requirements of products in the future using statistical models.

Logistics Engineer: engineers cost-efficient systems and processes.

Critical Skills for Success In Supply Chain

Technical Competencies:

Data analysis and interpretation.

Software expertise in supply chain (SAP, Oracle, Manhattan Associates).

Project management methods.

Transportation law Knowledge.

Methods of inventory optimization.

Soft Skills:

Pressure problem-solving

Cross-functional teamwork

Negotiation skills

Flexibility in the face of change.

Strategic thinking

Educational Options

A number of universities now offer specialized degrees in supply chain management. Careers can be significantly improved by some professional qualifications like APICS CSCP ( Certified Supply Chain Professional) or CPSM ( Certified Professional in Supply Management) provided by ISM.

Challenges and Solutions In Supply Chain And Logistics

Typical Challenges

Demand Volatility

Customer need forecasting is still a challenge especially when there is uncertainty in the economies. Companies have to mostly walk the thin line between enough inventory to meet demand and having too much money tied up.

Solution: Implement high technology forecasting software, stock safety, and develop agile supplier relationships capable of increasing quickly.

Global Disruptions

The operations can be stopped overnight by natural disasters, political unrest and health crisis. The ultra-lean globally dispersed supply chains demonstrated their vulnerabilities during the pandemic.

Remedy: Supplier base diversification, investment in supply chain visibility tools and contingency plans in various situations.

Last-Mile Complexity

The final stage of delivery is often the most expensive and complicated, particularly in cities with a high population density or in the countryside.

Solution: Explore other delivery methods like lockers, pick up stations and local retailer relationships. Optimize the routes using AI and consider crowd-sourced delivery models.

Talent Shortages

The industry is marred by an enormous skills gap with the senior staff retiring and the rapid pace of technology change that is outpacing training courses.

Remedy: Invest in human resource, work with educational institutions, and create congenial working conditions that will appeal to young professionals.

Best Practices to Excellence In Supply Chain.

Adopt Digital Transformation.

Companies who make use of technology to the best of their abilities have massive competitive advantages. Invest in:

On-demand supply chain systems to facilitate effective cooperation.

Total visibility real-time tracking systems.

Inventory control to reduce human error through automation.

Big data analytics to guide decision-making.

Create Good Relationships.

The supply chain management and logistics are based on relationships. Partner with carriers, suppliers, and customers, rather than transacting with them. Exchange of information, better collaboration, and win win.

Focus on Continuous Improvement.

Adopt strategies like Lean Six Sigma in an attempt to consciously uncover and eliminate waste. Incentivize creativity and empower the employees on all levels to suggest ways of improvement.

Put Customer Experience First.

The end customer has to be considered in every logistics decision. Fast, accurate, clear delivery will create loyalty and word of mouth. Invest in:

Tracking interfaces are easy to use.

Delay in communication is proactive.

Other delivery options.

Easy returns processes

Measure What Matters In Supply Chain Management

Measuring important business objectives: Key Performance Indicators (KPIs):

Precision in the rate of order fulfillment.

Percentage of on-time delivery

Inventory turnover ratio

Percentage of sales on transportation.

Perfect order rate

Cash-to-cash cycle time

The Data and Analyzing Role.

Modern logistics and supply chain management is big-data. Businesses are receiving data on millions of sources:

Instructional real-time demand point-of-sale systems.

Delivery pattern GPS tracking.

Inventory tracking Warehouse management systems.

Social media indicative of emerging trends.

Transportation affected by weather forecasts.

Indicators that predict a change in demand.

The trick consists in transforming the raw data into valuable insights. High-order analytics applications use machine learning to:

Trace patterns that humans can miss.

Optimize networks of thousands of variables.

Test scenarios through simulation to experiment with the strategies before actual use.

Give recommendations that would improve with time.

Global vs. Local Take into Account.

Companies have to choose between efficiency and responsiveness worldwide or locally. Economies of scale are realized by centralizing the operations; however, regional differentiation is destined to respond to the needs of distinct markets.

Global strategies are good in:

Capitalizing on the economies of scale.

Standardizing processes

Maximizing global networks

The sharing of best practices across the globe.

Local approaches offer:

Faster reaction to the market.

Cultural sensitivity

Adherence to local standards.

Lower transport distances

The most successful companies strike a balance between them, where they make use of global frameworks and leave regional flexibility.

Risk Management of Supply Chains.

Resilient supply chains predict and expect disruptions. Risk management involves:

Risk Identification:

Draw a map of the whole supply chain to get dependencies.

Determine single points of failure.

Observation of geopolitic dynamics.

Monitor supply chain financial stability.

Risk Mitigation:

Have many suppliers of key parts.

Hold strategic safety stock

Establish alternative transportation channels.

Insure supply chain.

Crisis Response:

Design elaborate contingency plans.

Established open communication processes.

Practice crisis scenarios simulated.

Build before crisis relationships.

Contemporary Supply Chain Sustainability.

Being environmentally responsible is not an option anymore.Supply chain management professionals have to implement sustainability in every decision:

Reducing Carbon Footprints:

Minimize the transportation paths.

Shipment consolidation to occupy less empty truck space.

Move towards low-emission vehicles.

Invest in e-fleets and alternative fuel.

Reducing Waste:

Develop reusable packaging systems.

Adopt reverse logistics on product returns and product recycling.

Reduce the sizes of packages to minimize the use of materials.

Co-operate with recycling facilities.

Ethical Sourcing:

Carry out supplier audit in labor practices.

Ensure fair pay in the supply chain.

Make sure verification of sustainable source of raw materials.

Encourage sourcing regions to develop.

The Future Outlook In Supply Chain Management

Even more dramatic developments are in the way of the next five years. The industry will keep undergoing changes through new technologies:

The Quantum Computing will solve optimization problems that are currently intractable, finding out unbiased optimal solutions among billions of potential solutions.

With 5G Networks, supply chains will become connected in reality because the IoT devices will be able to communicate in real-time with millions of other devices.

Smart Packaging, which is an advanced material, will be used to monitor the conditions of the products and automatically report to supply chain systems.

The Circular Economy Models will redesign the product lifecycle thinking, where the supply chains will be planned to reuse and recycle throughout their lifespan.

Cooperation with Innovators in the Industry.

Companies face these complex issues heading in the right direction, and it is necessary to collaborate with experienced providers of technology. QodeNEXT and other companies are helping businesses transform their supply chain operations in innovative software solutions, custom development and strategic consulting. An appropriate technology partner has the potential of driving digital transformation and enabling competitive forces within a dynamic marketplace.

Conclusion

The intersection place of logistics and supply chain management is between strategy, technology, and operations. Effective efficiency, local responsiveness, global reach, efficient cost management, and excellent service are balanced to bring success.

The profession has colossal potentials to individuals who embrace lifelong education and technological advancement. Whether dealing with the supply chain of a small firm or managing a global corporation with operations involving instruments such as Qodenext to automate your operations, the principles remain the same: plan, do, measure and continually improve.

Supply chain experts who understand these fundamentals and evolve into emerging technologies and evolving customer needs will drive their companies into the future as we move in 2025 and beyond. The supply chain pioneers of today are not cutting boxes anymore, you are forging the future of business, driving sustainable business, and creating the infrastructure that drives the global economy.

Frequently Asked Questions(FAQs)

1. What is Logistics and Supply Chain Management?

The supply chain management and logistics Logistics and supply chain management is the entire process involved in planning, executing and controlling the flow of goods and services. It involves organization of resources, information and activities of supplier to final consumers. The field is a mixture of planning and action operations to achieve products in their destinations successfully. It entails warehousing, transportation and inventory management and order fulfillment. Lastly, it is on the delivery of the appropriate product, to the appropriate place, at the appropriate time, and at the appropriate price.

2. What is the difference between supply chain management and logistics?

Logistics is nothing other than the transportation and warehousing of products in the supply chain. Supply chain management encompasses the whole supply chain which involves the procurement of raw materials till the final delivery. Logistics Logistics is operational and tactical, i.e. transportation, warehouses, and delivery. Supply chain management is tactical, which entails network design, forecasting, and supplier alliances. Regard logistics as an element that implements what is outlined by the supply chain management.

3. Is logistics included in supply chain management?

Yes, logistics is an important component of the entire supply chain management system. It is concerned with physical execution of transportation of goods along the supply line. Although the concept of the supply chain management includes the aspect of strategy, procurement, and relationships, the physical flow is organized by logistics. This is the working arm of strategy of supply chain which is logistics. Even the best strategies of supply chains could not survive without effective logistics.

4. What are the objectives of a logistics and supply chain management?

The key goals are:

– Cost saving: Saving the costs without compromising on the service quality.

– Efficiency and speed: Delivery of products in the most efficient way.

– Customer satisfaction: on-time delivery and service provisions.

– Control and visibility: Tracking of the product and information in transit.

– Risk management: Developing discontinuity immunity and business continuity.

5. What do you consider as an example of supply chain management?

One example of how supply chain management is currently practiced at Amazon is its fulfillment network. The company buys goods of thousands of suppliers in the world and stocks them in strategic fulfillment centers. Complex algorithms determine the demand and inventory of stock that are closer to customers. Picking, packaging, and shipping take only hours when orders are received by automated systems. This end-to-end supply chain excellence is observed in the entire process including vendor to doorstep delivery.

6. What is the scope of logistics versus supply chain management?

The term logistics scope is associated with the functions of transportation, warehouse, inventory control, and order processing. Procurement, supplier partnerships, demand planning, production planning and customer service are the matters of supply chain management. Logistics operates on functional boundaries where efficiency of movement is of emphasis. The supply chain management collaborates at organizational levels and coordinates with several partners and stakeholders. The disparity in scope describes logistics as an execution-based and supply chain management as a coordination-based one.

7. How is the time frame different between logistics and supply chain management?

Logistics tends to operate at the shorter time scale, with its focus being on the urgent needs of the operations and daily implementation. The supply chain management operates at longer strategic calendars and plans months or even years ahead. Logistics answers questions like: How shall we get this order out to-day? whereas supply chain asks itself the question of where it finds its next distribution facility? The scale of time difference is the reflection of the tactical orientation of logistics versus the strategic orientation of supply chain. The two timescales should be synchronized to achieve maximum performance.

8. What are some typical supply chain and logistics challenges?

Primary challenges are:

– Unpredictable demand: The customer demand is volatile, making it difficult to plan.

– Supply disruption: gridlocks are brought about by natural disasters, political tension or a supplier breakdown.

– Margins diminish due to higher expenses: Fuel costs, shortage of labor, inflation.

– Technology integration: The implementation of MRA and integration of different systems remain a challenge.

– Sustainability pressure: It is a matter of profitability and environmental responsibility, and that is innovation.