In the dynamic landscape of modern warehouses, the quest for increased efficiency is a constant pursuit. As businesses strive to meet growing consumer demands and streamline their operations, innovative technologies play a pivotal role in shaping the future of logistics.

The voice picking technology is transforming the operations in the global warehouses where the market is projected to hit $2.9 billion dollars in 2025 (15.3% growth per annum). It is a hands-free voice-driven system that enables workers to be guided by their headsets on picking instructions and leave their hands and eyes free to achieve high accuracy rates of over 99.9 and a 50 percent increase in productivity.

You will learn in this detailed manual how voice picking technology works, how it can be measured to produce benefits, what are the difficulties in implementing it, and whether it is the right tool to introduce in your warehouse.

Let’s get started!

Defining Voice Picking Technology:

Voice picking in warehouse operations is a revolutionizing and transformative solution, leveraging voice recognition for order fulfilment. This hands-free, paperless system directs workers through easy-to-understand voice prompts, enhancing accuracy and efficiency.

Connected to the warehouse management system, the technology converts orders into voice commands heard through operators’ headphones. Workers verbally confirm their movements, automatically updating the system.

This streamlined process eliminates paper-based errors, reduces labour costs, and allows workers to focus on precise item selection. Overall, voice-picking technology accelerates order preparation, making warehouse operations more agile and error-resistant.

How Voice Picking Technology Works:

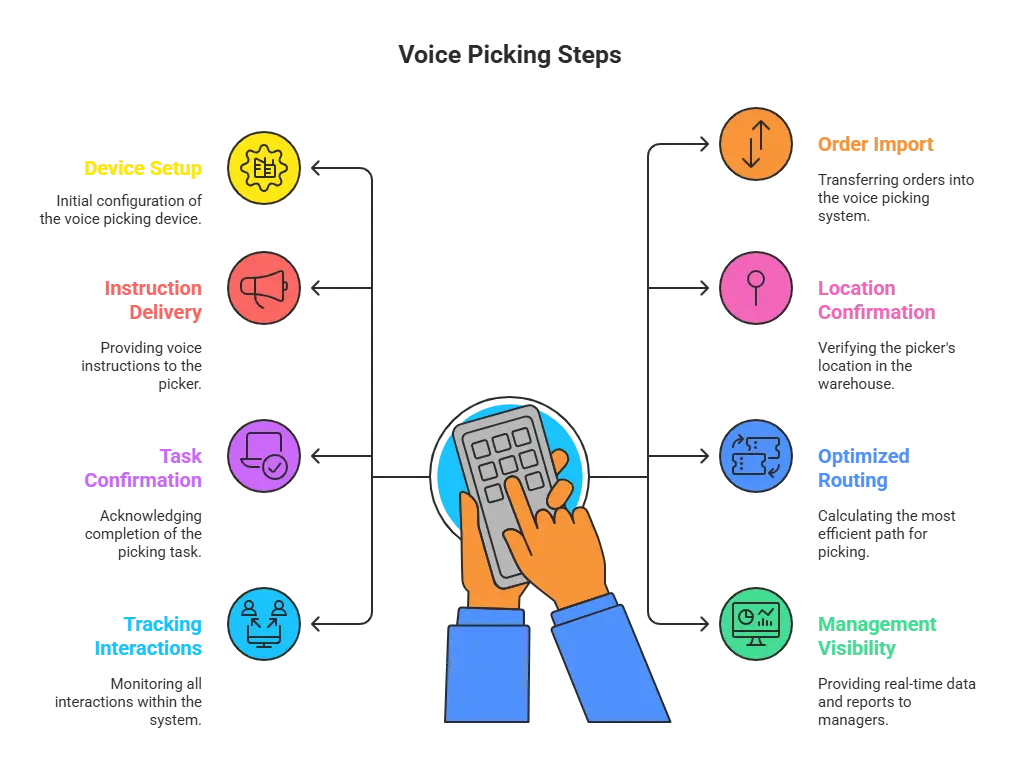

Here’s a breakdown of how voice-picking technology works:

Device Setup:

Workers are equipped with a specialized mobile computer connected to a headset featuring a microphone and a barcode scanner.

Order Import and Sequencing:

Customer orders are imported from the warehouse management system (WMS) or enterprise resource planning (ERP) software. The orders are recorded, sequenced, and released for processing.

Instruction Delivery:

The voice-picking device provides verbal instructions to the warehouse worker, specifying picking tasks and their respective locations.

Location Confirmation:

When the worker reaches a designated location, they verbally confirm confirmation digits to verify the location and bin.

Task Confirmation:

The system confirms the aisle or section and provides the operator with the pick quantity, which the operator verbally confirms upon completion.

Optimized Routing:

After completing a task, the system guides the operator to the next pick location, optimizing the path for efficiency.

Tracking Interactions:

All interactions between the worker and the voice application are tracked, allowing managers to monitor order fulfilment progress.

Management Visibility and Reporting:

Advanced systems offer reporting and management tools for workflow management, real-time exception handling, and overall productivity tracking, enhancing warehouse operations effectiveness.

Benefits of Voice Picking Technology:

Here’s a detailed overview of the benefits of voice picking technology in a warehouse or distribution centre:

Increased Productivity:

With hands-free from handling devices or paper instructions, workers can concentrate on picking the correct products. Removing these distractions often leads to a notable increase in productivity among pickers

Accurate Order Processing:

Voice-directed work aids concentration, enabling faster location and accurate picking of items. This swift and precise order processing enhances customer satisfaction by ensuring timely and error-free deliveries.

Reduce Errors:

The elimination of distractions, coupled with verbal confirmation for each pick, significantly reduces the likelihood of picking errors. The hands-free nature of voice picking minimizes the risk associated with traditional manual methods.

Improved Inventory Counts:

Enhanced picking accuracy leads to improved inventory counts. Organizing items in a way that aligns with the voice-picking process further streamlines the inventory management process, contributing to overall supply chain efficiency.

Less Training:

Voice picking is easy to learn, with simple, step-by-step commands. This ease of use minimizes training time, making onboarding more efficient and reducing the learning curve for new employees.

Versatility in Applications:

Voice-picking technology can be applied to various warehouse processes, including cross-docking, picking to conveyor systems, pick-by-line, putaway, and inventory management. Its versatility makes it a valuable tool across different aspects of voice picking in warehouse operations.

Boosted Accuracy of Orders:

Voice-directed work allows users to focus on tasks without the need to read instructions. This results in quicker identification of items, selection of the right quantity, and accurate placement, ultimately leading to higher order accuracy and customer satisfaction.

Increased Inventory Accuracy:

Better picking accuracy contributes to improved inventory counts. The combination of organized warehouse layouts and the precision of voice-picking technology enhances a business’s ability to manage inventory more accurately.

Reduced Picking Errors:

Distractions are minimized, reducing the chances of incorrect picks caused by looking away from the picking area. Verbal confirmation for each pick ensures higher order accuracy rates, potentially reducing the average error rate to as low as one error per 1,000 picks.

Challenges to Deal With:

Although voice picking is a viable option to include in your warehouse, there are a few challenges to look out for. We’ve listed some below:

Initial Implementation Costs:

The upfront investment required for implementing voice picking technology, including purchasing devices and integrating with existing systems, can be a significant challenge for businesses with tight budgets.

Integration with Existing Systems:

Compatibility issues may arise when integrating voice-picking technology with legacy warehouse management systems (WMS) or enterprise resource planning (ERP) software. Ensuring seamless integration is crucial for a smooth transition.

- Worker Resistance and Training:

Employees accustomed to traditional picking methods may initially resist the adoption of voice technology. Adequate training programs are essential to overcome resistance and ensure efficient utilization of the new system.

- Accents and Dialects:

Voice recognition technology may face challenges in accurately understanding commands in environments with diverse accents and dialects. This can lead to errors in task execution and impact overall efficiency.

- Environmental Noise and Interference:

Noisy warehouse environments can pose challenges for voice recognition systems. Interference from background noise or equipment may affect the accuracy of voice commands, requiring careful consideration of the work environment.

- Scalability Issues:

As businesses grow, the scalability of voice-picking technology becomes crucial. Ensuring that the system can efficiently handle increased order volumes and warehouse complexity is a challenge that requires thoughtful planning.

Voice Picking Technology: ROI and Cost

The adoption of voice picking technology would entail a one time investment in special headsets, software integration and training. The payback period (ROI) is however realized in 6 to 12 months, due to the quantifiable gains in picking error, speed of order, and man power efficiency.

Warehouses with paper-based errors are often able to save up to 25-30 percent productivity and close to 90 percent error reduction through the eradication of paper-based errors and cutting on scanning time by almost 90 percent. Though the initial cost of the set up might be expensive, the long term effects of the technology on operational efficiency, less rework and shorter order processing time will result in significant savings in expenses in the long term.

Concisely, voice picking is not a one-time expense but a scalable investment which always pays off in the form of increased accuracy, happier employees as well as a rapidly responsive and quicker warehouse.

Conclusion:

In conclusion, voice-picking technology stands at the forefront of warehouse innovation, driving efficiency, accuracy, and streamlined operations. Its hands-free, paperless approach transforms order fulfillment, reducing errors, and enhancing overall productivity.

While challenges exist, the benefits outweigh them, making voice picking an invaluable asset in the evolving logistics landscape. As warehouses embrace this technology, they position themselves for success in meeting heightened consumer demands.

To seamlessly integrate voice picking and overcome implementation challenges, consider Qodenext—an industry leader in warehouse technology solutions, ensuring a future-ready and efficient warehouse management system. Ready to transform your warehouse operations? Contact Qodenext today for a Voice Picking System Feasibility Study & Custom Quote tailored for your logistics needs!

FAQ: Role of Voice Picking Technology in a Warehouse

1. Examples of voice-picking technology in warehouse

Leading examples of voice-picking technology include systems like Vocollect, Honeywell Voice, and Zebra Technologies. These solutions enhance warehouse efficiency by providing hands-free, voice-guided instructions to workers during the picking process.

2. What are the three most voice-picking technologies in a warehouse?

Prominent voice-picking technologies in warehouses are Vocollect by Honeywell, Voxware, and Lucas Systems. These systems streamline operations by employing voice commands for accurate and efficient order fulfilment.

3. How accurate is voice-picking technology?

Voice-picking technology boasts remarkable accuracy rates, often exceeding 99%. Real-time distribution systems (RDS) with integrated barcode scan validation can achieve precision levels of 99.99%, minimizing errors and enhancing overall reliability in warehouse order-picking processes.

4. What does it mean to know whether voice picking technology will be suitable in my warehouse?

Voice picking technology is best suited for warehouses with a large number of SKUs, frequent order reconfigurations, or moving merchandise. When your operations have a problem with error of manual mistakes, slow picking speed or they have problems in training new employees, voice picking would increase efficiency significantly. It works particularly well in distribution centers, e-commerce, and retail warehouses where there is a need to be precise and quick in the order fulfillment.

5. Is the voice picking technology efficient in a noisy or cold environment?

Yes, voice picking systems that are contemporary are developed to work properly even in the noisy or temperature-regulated environment like cold warehouses. High-tech noise-cancellation microphones and adaptive speech recognition enable labourers to speak properly, even when there is background noise by the machinery. There are also numerous vendors of specialized headsets that can be used in the conditions of the cold or freezer, which makes the headset work consistently in any conditions.

6. What is the duration of training of warehouse workers to learn how to use voice picking systems?

Warehouse employees usually do not require much time to be trained on voice picking systems. The majority of employees can learn to be fully trained in 2 to 4 hours of training. The system is also dramatically less involved in the learning curve due to the use of simple voice prompts and verbal confirmations, even when it comes to new or seasonal workers. This convenience makes warehouses adopt the technology without much inconvenience.

7. Is it possible to integrate voice picking with the current WMS or ERP systems?

Yes, the majority of current voice picking systems are constructed to be integrated smoothly with the popular Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) software. Integration enables real-time exchange of data to ensure that the order updates, movement of stocks, and tracking the productivity is in balance. A reliable vendor is able to make integrations to fit existing warehouse procedures so that implementation can proceed without disrupting workflow.

8. What type of return on investment is achievable with voice picking?

Typical companies realize a return on investment of 20–30% in higher productivity and error reductions of up to 90% when they implement voice picking. These gains are achieved through hands-free, eyes-on work and shorter pick paths, as well as less time spent double-checking orders. Over the years, the saving on the operational cost far surpasses the cost for setting up, vocalization picking is one of the most cost-effective warehouse automation tool.