If a single faulty part can crash a whole machine, imagine what a single non-compliant supplier can do to your business.

Yes, that’s the reality many supply chains face today.

As networks become more global and complex, the risk of operational, ethical, legal, and financial failure increases. This is where supply chain compliance steps in. Not as a checkbox exercise, but as a critical foundation for business resilience.

Let’s get into how supply chain audits and compliance checks help protect your brand, reduce risk, and build trust across every tier of your supply network.

Come, let’s straight into it.

Why Compliance Audits Are No Longer Optional

Today’s consumers demand transparency.

Governments are tightening regulations. Investors want ethical sourcing. A single misstep in your sourcing or production chain can lead to major fines, product recalls, or worse public backlash.

A proper supply chain audit ensures that your suppliers (and their suppliers) meet required standards for labor laws, environmental impact, cybersecurity, safety protocols, and more.

More than just meeting rules, audits help ensure supply chain integrity. They ensure that your operations are ethical, legal, and sustainable, from end to end.

Now that we understand the need, let’s explore what supply chain audits really involve.

What Happens in a Supply Chain Audit?

A supply chain audit is a structured review of supplier performance, policies, and practices. These audits can be conducted by your team, a third party, or government authorities.

Audits typically check for:

- Regulatory compliance (e.g., labor laws, environmental standards)

- Operational risks (quality, delivery timelines, cyber vulnerabilities)

- Ethical practices (fair wages, child labor, worker safety)

- Documentation (licenses, safety certifications, data handling policies)

A solid supplier due diligence checklist often covers these areas in advance, reducing the risk of surprises during an audit. There are different types of audits – announced, unannounced, or remote – depending on the region, industry, and risk level.

Now that we’ve covered what audits look like, let’s talk about the real business benefits.

How Supply Chain Audits Protect Business Integrity

Think of audits not as roadblocks, but as GPS for your operations. They point out where you might go off-course before it’s too late.

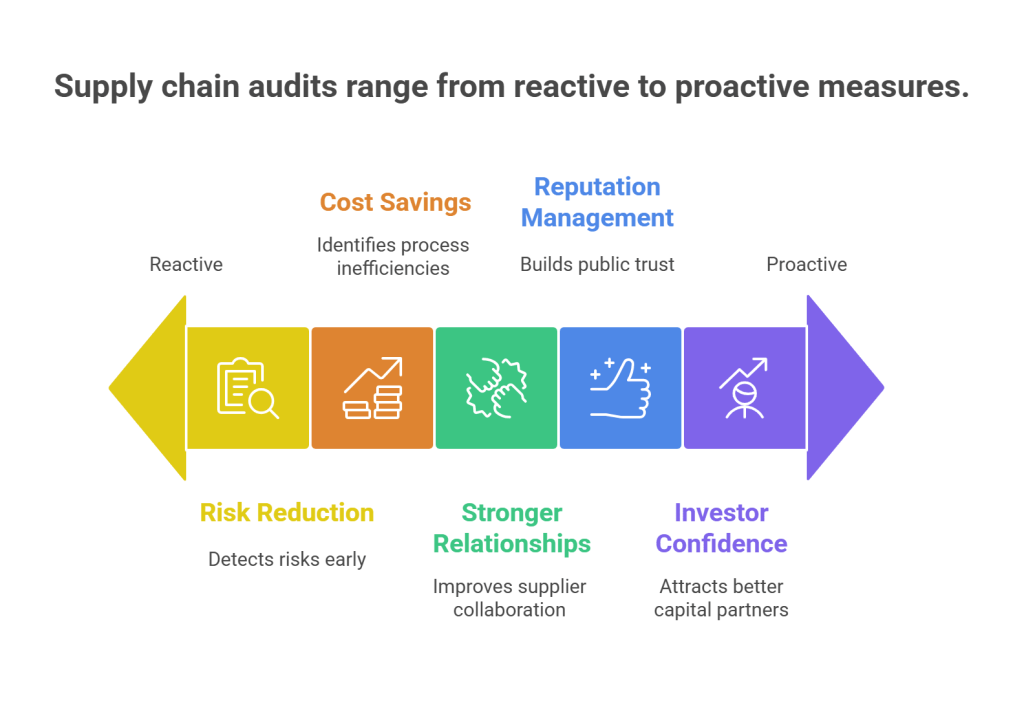

Key benefits of supply chain audits include:

- Risk reduction: Early detection of legal, environmental, or reputational risks

- Stronger supplier relationships: Audits often lead to improved collaboration

- Cost savings: Identifying inefficiencies in processes, sourcing, or transport

- Reputation management: Being proactive about supply chain compliance builds public trust

- Investor confidence: Transparent, compliant operations attract better capital partners

If you want to sleep well at night, knowing your supply chain won’t implode, audits are your friend.

Knowing the benefits, let’s now focus on how to actually perform effective due diligence.

The Role of Due Diligence in Supply Chain Compliance

Before you sign a contract with a supplier, you need to know more than their prices. That’s where supply chain due diligence comes in.

It’s the act of verifying that a supplier follows all relevant laws, regulations, and ethical practices – before they become a risk to you.

A good supplier due diligence checklist will look at:

- Corporate structure and financial health

- Labor policies and workforce conditions

- Environmental practices

- Cybersecurity infrastructure

- Subcontractor policies

This is about due diligence compliance – being able to prove you did your homework, in case something goes wrong.

Now that we understand the process of vetting suppliers, let’s look at common challenges.

Common Pitfalls in Supply Chain Audits (and How to Avoid Them)

While the concept of compliance in supply chain management is straightforward, executing it across multiple regions and vendors isn’t.

Some common audit challenges include:

- Language and cultural barriers: Miscommunication can lead to inaccurate reporting

- Audit fatigue: Suppliers overwhelmed by frequent checks may cut corners

- Data gaps: Missing or incomplete documentation can derail the process

- Limited visibility into Tier 2 and Tier 3 suppliers

How to overcome these?

- Standardize your audit process and documentation

- Rotate audit schedules and types (some remote, some unannounced)

- Use technology for better visibility (e.g., compliance platforms, blockchain logs)

Let’s see how technology is helping companies stay ahead.

How Technology Enhances Audit Accuracy and Efficiency

Gone are the days of audits done on paper and stored in filing cabinets. Today’s tools help automate and track every aspect of supply chain audits.

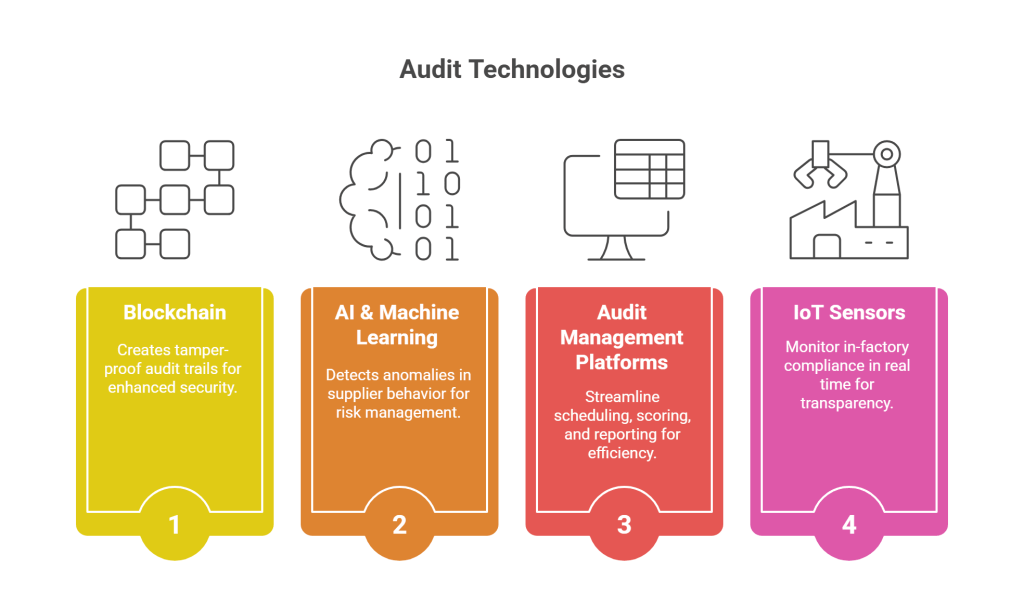

Technologies that help:

- Blockchain: Creates tamper-proof audit trails

- AI & Machine Learning: Detects anomalies in supplier behavior

- Audit Management Platforms: Streamline scheduling, scoring, and reporting

- IoT Sensors: Monitor in-factory compliance in real time

These tools don’t just save time – they improve the accuracy and accountability of your entire supply chain compliance process.

Finally, let’s bring it all together with some examples.

Brands That Prioritize Supply Chain Compliance

Apple: Conducts annual supplier responsibility audits. In 2022 alone, they removed 13 suppliers for failing to meet their code of conduct.

Nestlé: Uses a digital traceability system to monitor its cocoa supply chain, ensuring ethical sourcing from farm to factory.

Patagonia: Goes beyond basic audits by building long-term relationships with suppliers and investing in training programs to improve standards.

These companies view supply chain compliance not as overhead but as a competitive advantage.

FAQs : The Hidden Value of Supply Chain Compliance Audits

1. How often should supply chain audits be conducted?

It depends on the industry and risk level, but annually is a common benchmark. High-risk sectors may require biannual or ongoing audits.

2. What should a supplier due diligence checklist include?

It should cover legal, environmental, labor, and cybersecurity metrics, as well as financial stability and subcontractor management.

3. Is third-party auditing necessary?

While internal audits are useful, third-party auditors offer more objectivity, credibility, and can reduce bias in results.

4. What happens if a supplier fails an audit?

You can issue corrective actions, place them on probation, or end the relationship depending on severity and response.

5. Can digital tools really replace in-person audits?

Not fully, but they are great for ongoing monitoring and supplementing physical checks, especially in global operations.

Conclusion

Integrity isn’t just a value, it’s a business strategy. Regular supply chain audits help you catch small cracks before they become huge liabilities.

Whether it’s staying ahead of regulations, building consumer trust, or protecting your bottom line, strong compliance in supply chain management isn’t negotiable.

Start with a clear supplier due diligence checklist, invest in the right tools, and make compliance a culture, not a crisis response.