Introduction

As businesses grow, it becomes clear that managing inventory is no longer just about counting boxes. Growth adds complexity with more SKUs, more locations, and heightened customer expectations. Systems that worked well with 1,000 orders a month struggle at 10,000.That’s where a warehouse management system (WMS) comes in—serving not just as a digital record but as the core of a growing supply chain. It connects people, processes, and products so businesses can expand without chaos.

In this blog, we’ll look at what makes a warehouse inventory management system scalable, how modern solutions are built for growth, and which companies have successfully made this transition.

Why Scalability Matters in Modern Warehousing

For any growing company, scaling can be both exciting and risky. Orders increase, product lines expand, and fulfillment networks stretch across regions. Without the right systems in place, the very success that drives growth can also create bottlenecks.

A warehouse management system (WMS) ensures that scaling doesn’t turn into stress. It keeps every pallet, box, and SKU exactly where it should be, even when volumes rise.

Here’s why scalability should be a top priority:

- Demand volatility: Seasonal peaks or flash sales can double warehouse volume overnight.

- Expansion: Multiple warehouse sites need synchronized visibility.

- Labor efficiency: As headcount rises, standardized digital workflows prevent errors.

- Customer expectations: Same-day and next-day delivery leave no room for delays.

Growth doesn’t have to lead to chaos—especially when your warehouse inventory management system grows alongside you. Now that we understand why scalability is crucial, let’s identify what makes a system truly scalable.

What Makes a Warehouse Management System Truly Scalable

A scalable WMS is defined by how well it handles complexity. Here are five attributes that distinguish a basic setup from a future-ready system:

| Attribute | Why It Matters | Example in Action |

|---|---|---|

| Modularity | Add or remove functions as the business grows. | A startup can begin with basic inventory tracking and later add labor management or returns modules. |

| Integration | Connects with ERP, e-commerce, and transport systems. | Shopify warehouses integrate their WMS with storefront and carrier APIs for real-time updates. |

| Real-time Data | Every item tracked to its exact bin or bay instantly. | Amazon’s fulfillment centers rely on real-time scanning to update millions of SKUs per minute. |

| Automation-ready | Supports robotics, conveyor systems, and sensors. | DHL’s automated warehouses use a WMS that coordinates workers and robots together. |

| Cloud Scalability | Handles surges in users, data, or orders without delay. | A cloud-based warehouse management system allows businesses to expand globally without new infrastructure. |

When these attributes work together, a business can add new locations, products, or channels—and the WMS simply adjusts.

How a Warehouse Inventory Management System Works

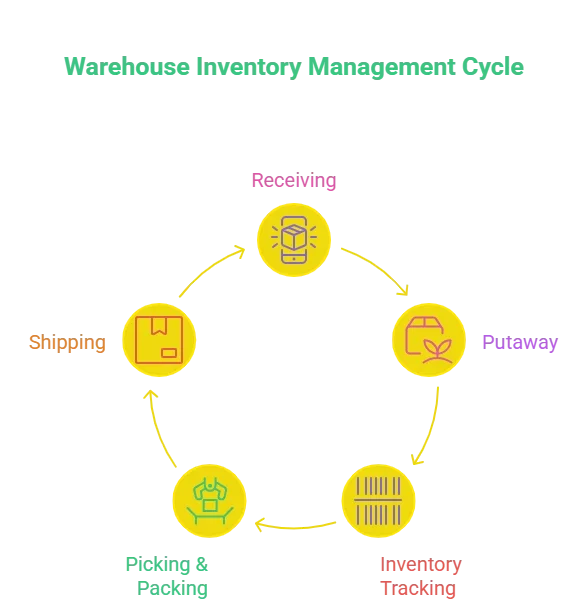

Think of a warehouse management system as a digital conductor managing various tasks: receiving, putaway, picking, packing, and shipping.

Typical Workflow:

- Receiving: The system logs incoming goods, checks purchase orders, and assigns storage locations.

- Putaway: Workers or robots store products in ideal spots based on size, demand, and access frequency.

- Inventory Tracking: Every item receives a unique barcode or RFID tag linked to real-time data.

- Picking & Packing: Orders trigger optimized picking routes to reduce travel time.

- Shipping: The system connects with TMS or courier APIs to generate labels, track shipments, and confirm deliveries.

Each step feeds into a central data layer, providing live visibility and analytics—vital for fast-growing businesses that can’t afford uncertainty.

How Industry Leaders Are Making the Most of Warehouse Management Systems

The best way to understand a system’s capabilities is to see it in action. Here are some real-world examples of scalable WMS implementations:

- Nike – Data-driven fulfillment:

Nike operates some of the most advanced distribution centers globally. Its WMS integrates robotics with real-time analytics, enabling faster order fulfillment during major product launches. - IKEA – Flexibility through modular design:

IKEA’s logistics model uses modular design, allowing global warehouses to customize processes while maintaining standardization. - FedEx – Cloud-based scalability:

FedEx uses a cloud-based WMS that synchronizes inventory and shipping data across hundreds of facilities. The system scales automatically during seasonal surges like Black Friday. - H&M – Sustainable automation:

H&M’s fulfillment centers combine a WMS with automated sortation and solar-powered facilities—supporting both scalability and sustainability.

These examples show that scalability is about building one intelligent system that grows as operations expand.

The Shift Toward Cloud-Based Warehouse Management Systems

A decade ago, WMS platforms were mostly on-premise—requiring costly servers, IT teams, and manual upgrades. Today, the model has shifted toward cloud-based warehouse management systems.

Here’s why the cloud is becoming the preferred option:

- Elastic capacity: Instantly scale computing power during order surges.

- Remote access: Manage multiple warehouses from anywhere in the world.

- Faster deployment: Go live in weeks instead of months.

- Lower upfront cost: Pay as you grow instead of buying perpetual licenses.

- Continuous improvement: Automatic updates with no downtime.

Companies like Prologis and Maersk now run distributed logistics networks through cloud systems, enabling unified visibility across continents.

Automation and AI: The New Layer of Scalability

Modern WMS platforms increasingly incorporate AI and machine learning to enhance decision-making and operational efficiency.

How it works:

- Dynamic Slotting: AI predicts fast-moving products and repositions them closer to dispatch areas.

- Predictive Maintenance: Sensors identify when equipment might fail, reducing downtime.

- Labor Optimization: Algorithms assign tasks based on worker speed and skill.

- Order Prioritization: AI determines which orders to process first based on deadlines and customer priorities.

These advancements redefine scalability—making it not just larger, but smarter.

How to Choose the Right Warehouse Management System

Picking a scalable warehouse inventory management system isn’t just about selecting software; it’s about matching technology to your growth stage.

| Step | Focus | Questions to Ask |

|---|---|---|

| 1. Define Scale Goals | What expansion are you planning? | How many SKUs or warehouses in the next three years? |

| 2. Assess Integration Needs | What systems must it connect to? | Are ERP, CRM, or TMS integrations required? |

| 3. Evaluate Flexibility | Can modules be added later? | Does it support multi-warehouse logic? |

| 4. Compare Deployment Models | On-premise vs. cloud. | Which offers faster ROI for your scale? |

| 5. Pilot Before Rollout | Test functionality on one site. | Does it meet KPIs like picking accuracy or cycle time? |

The goal isn’t to find the most powerful system—it’s to find the most adaptable one for your current and future needs.

The Cost of Staying Static

For businesses still relying on spreadsheets or outdated software, the true cost isn’t the license savings—it’s the lost opportunities.

Without a modern WMS, companies face:

- Stock discrepancies and inaccurate counts

- Lost orders during high demand

- Poor visibility into slow-moving SKUs

- Rising manual errors with higher volumes

- Low staff productivity

By contrast, scalable systems can reduce order processing time by up to 40% and improve inventory accuracy to 99% or higher. That’s not just efficiency—it’s a competitive edge.

Conclusion

True scalability isn’t about size. It’s about stability. A business that can double its output without doubling its effort is truly scalable.

A modern warehouse management system delivers exactly that.

The right warehouse inventory management system helps businesses grow without growing pains – keeping control, consistency, and customer satisfaction intact.

As companies evolve from single-site operations to global networks, the warehouse becomes the beating heart of the supply chain. And like any strong heart, it needs a system that grows with it.

FAQs: Scalable Warehouse Inventory Management System That Grows With You

1. What’s the difference between a warehouse management system and inventory management software?

An inventory system tracks quantities, while a WMS manages the physical flow of goods through storage, picking, and shipping.

2. Are cloud-based warehouse management systems secure?

Yes. Top providers use encrypted transmission, multi-factor authentication, and regular security audits.

3. How quickly can a company implement a scalable WMS?

Small warehouses can go live in 6–8 weeks; larger enterprises may phase rollout over 3–6 months.

4. What are the top warehouse management system examples today?

Leaders include Manhattan Associates, Blue Yonder, SAP Extended Warehouse Management, and Oracle Cloud WMS.

5. How can a WMS support sustainability goals?

Modern systems optimize routes, reduce paper use, and balance energy consumption for greener logistics.