Every time a customer clicks “Buy Now,” a silent chain of events begins. The order travels from a website to warehouses, suppliers, delivery partners, and back-end systems – all within seconds.

That orchestration, from confirmation to delivery, is the essence of order management.

In the era of multi-channel selling, where companies sell on their own websites, on marketplaces, and in physical stores all at once, becoming an order management pro isn’t just a nice to have — it’s what separates the smooth, customer-obsessed brands from the rest.

Here’s what order management is in reality, how it functions, and how software and KPIs can assist merchants in converting each transaction into a seamless, money-making event.

Understanding the Concept of Order Management

Put very simply, order management is the activity of monitoring and satisfying customer orders – from the time an order is placed up to the moment it’s delivered (and sometimes even later, in the form of returns or exchanges).

But in real life, it’s shipping a lot more than just a package.

It’s people, systems and inventory aligned across all channels to deliver the right product to the right customer at the right time.

In management theory, this aligns with the order principle of management – the idea that “everything and everyone must have a proper place.” Applied to business, it means every order, SKU, and workflow should be organized systematically not reactively.

When businesses get order management right, they gain consistency, accuracy, and trust – the foundations of customer loyalty.

Now that we understand what it means, let’s look at the system that powers it.

What Is an Order Management System (OMS)?

An order management system is the technology that centralizes, automates, and monitors every step of the order journey. It acts as a control tower that connects sales channels, inventory, warehouses, and logistics – ensuring seamless coordination.

Think of it as the “brain” of your commerce operations.

An order management system typically handles:

- Order capture from all sales channels (website, store, marketplace, etc.)

- Inventory visibility across warehouses and fulfillment centers

- Order routing to the optimal fulfillment point based on stock, cost, and proximity

- Payment verification and fraud screening

- Shipping and tracking updates

- Returns and reverse logistics management

Nike’s global retail operations use a cloud-based order management system to unify sales data from its website, app, and stores. When a customer orders a pair of shoes online, the system decides whether to ship from a warehouse or fulfill it from the nearest retail store – reducing delivery time and maximizing efficiency.

That’s the kind of orchestration modern order management enables.

Now that we’ve met the system, let’s walk through the step-by-step process behind it.

The Order Management Process

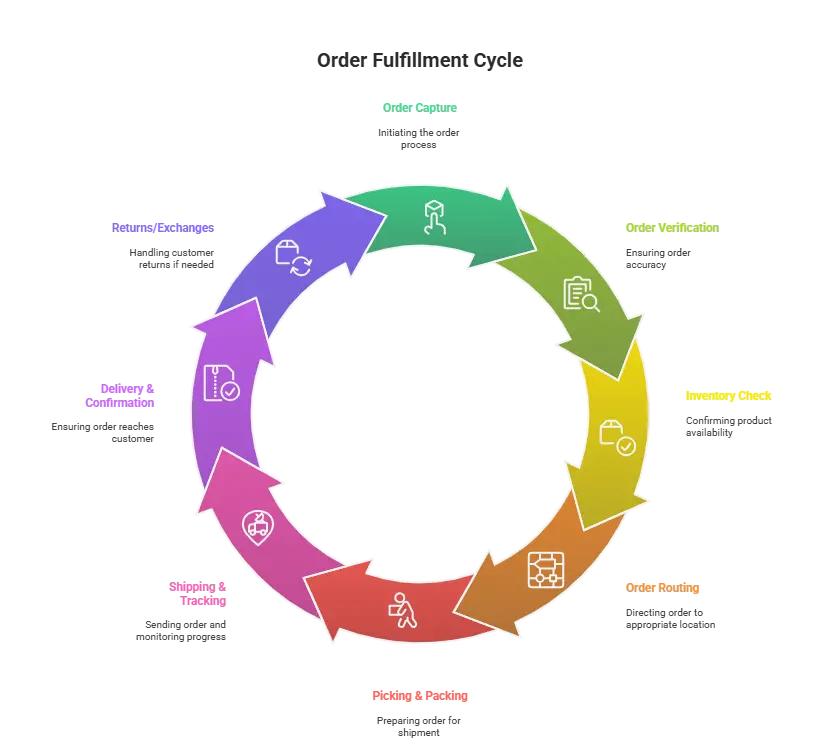

Every order follows a series of well-defined steps that together form the order management process.

Here’s how it unfolds:

| Stage | Description | Objective |

| 1. Order Capture | The customer places an order online, in-store, or via marketplace | Record all order details accurately. |

| 2. Order Verification | Payment is validated, and fraud checks are completed. | Ensure secure, legitimate transactions. |

| 3. Inventory Check | The order management system checks stock availability and location. | Confirm if items are available and where. |

| 4. Order Routing | The system assigns fulfillment to the best warehouse or store. | Minimize delivery time and shipping cost. |

| 5. Picking & Packing | Items are retrieved, packed, and labeled for shipment. | Prepare for dispatch efficiently. |

| 6. Shipping & Tracking | Orders are handed to carriers; customers receive tracking details. | Maintain transparency and speed. |

| 7. Delivery & Confirmation | The order reaches the customer; delivery is confirmed. | Close the fulfillment loop. |

| 8. Returns/Exchanges (if applicable) | Returned goods are processed and restocked. | Maintain customer satisfaction and control loss. |

Each of these steps relies on clear communication and real-time data – which is why automation through an order management system is so powerful.

Now that the process is clear, let’s see how companies measure performance using KPIs.

Key KPIs for Effective Order Management

To know whether your order management process is working efficiently, you need metrics that measure both speed and accuracy.

Here are some of the most important order management KPIs to track:

| KPI | What It Measures | Why It Matters |

| Order Cycle Time | Time from order placement to delivery. | Shorter cycles mean faster fulfillment. |

| Perfect Order Rate | Percentage of orders delivered without error or delay. | Reflects reliability and customer satisfaction. |

| Order Accuracy | Number of orders shipped correctly vs. total orders. | Directly tied to customer trust. |

| Return Rate | Percentage of orders returned by customers. | Indicates product or fulfillment issues. |

| Inventory Turnover | How fast inventory sells and replenishes. | Reveals stock efficiency and cash flow health. |

| Order Fill Rate | Percentage of customer demand met without backorders. | Higher rates mean better inventory alignment. |

Companies like Amazon and Walmart obsess over these KPIs because even a 1% improvement in order accuracy or cycle time can save millions annually.

Now that we know how success is measured, let’s explore the business benefits that come with getting it right.

Benefits of a Well-Designed Order Management System

A seamless order management system doesn’t just move products – it transforms how a business operates.

Experts list improved fulfilment speed, channel consolidation and smarter inventory as key benefits of today’s OMS.

Here’s what companies typically gain:

1. Unified Visibility

A centralized system gives real-time updates on inventory, order status, and fulfillment – across all channels and locations. This eliminates duplication and manual data entry.

2. Improved Customer Experience

Customers can track their orders in real time and receive accurate delivery timelines. Faster, more transparent service builds trust.

3. Reduced Operational Costs

Automation in the order management process minimizes manual errors, optimizes labor, and cuts unnecessary shipping expenses.

4. Scalability and Flexibility

A modern order management system scales effortlessly with growing order volumes or new sales channels – especially when cloud-based.

5. Smarter Decision-Making

Access to real-time analytics helps managers forecast demand, balance inventory, and optimize carrier partnerships.

Cloud-Based Order Management: The New Standard

Gone are the days of systems tied to on-premise servers.

Today’s businesses need agility, and that’s why most are shifting to cloud-based order management systems.

Benefits of Cloud Deployment:

- Anywhere access: Manage orders from any device, anywhere in the world.

- Elastic scalability: Handle sales spikes during holidays or campaigns without downtime.

- Lower IT costs: No heavy hardware or maintenance expenses.

- Automatic updates: New features roll out continuously with minimal disruption.

Example:

Shopify and Salesforce Commerce Cloud offer integrated order management systems that let retailers manage inventory, orders, and returns from a single cloud dashboard. Small businesses can start small and scale globally without changing infrastructure.

A cloud-based order management system turns growth from a logistical challenge into an operational advantage.

Now that we’ve covered technology, let’s look at how order management aligns with larger business strategy.

Strategic Value of Order Management in Business Growth

Order fulfillment isn’t just a back-end task – it’s a direct reflection of brand reliability. In competitive markets, where customer loyalty is fragile, how well a company manages orders can make or break its reputation.

A good order management framework enables:

- Omnichannel consistency: Customers experience the same speed and reliability whether they order online, in-store, or via mobile.

- Better working capital management: Real-time visibility prevents overstocking or stockouts.

- Data-driven forecasting: Predictive insights support smarter procurement and marketing.

- Faster market expansion: Businesses can easily launch in new regions without building new systems.

This strategic approach mirrors the order principle of management – a disciplined alignment of people and processes to maintain order, even in rapid growth.

Now that we’ve seen its strategic role, let’s tie everything together.

Conclusion

Efficient order management is not just about moving products; it’s about managing promises.

Every fulfilled order represents a promise kept – and every delay or error, a missed opportunity.

In short, effective order management blends technology and discipline – the modern expression of the order principle of management itself. Businesses that master it don’t just process transactions; they build trust at scale.

FAQs

1. What is the difference between order management and inventory management?

Inventory management tracks what’s in stock; order management oversees how that stock moves from warehouse to customer.

2. How long does it take to implement an order management system?

Cloud-based systems can go live within weeks. Enterprise-level OMS platforms typically take 3–6 months depending on complexity.

3. What are some leading order management system examples?

Top platforms include Oracle NetSuite OMS, SAP Order Management, Salesforce Order Management, and Manhattan Active Omni.

4. How does automation improve the order management process?

Automation eliminates manual steps, reduces human error, and ensures faster verification, routing, and fulfillment.

5. How can small businesses benefit from a cloud-based OMS?

They gain enterprise-level visibility and automation without heavy IT investment, enabling them to compete with larger players.

6. What are the critical features to look for in an order management system?

Balanced It’s important that your OMS solution provides real-time inventory tracking, automated order routing, and integration with various sales channels. SHOP among the cloud-based solutions that will also feature scalability, analytics dashboards, and returns handling — all vital for managing An prices multichannel. In other words, an OMS should enable your team to work smarter, not harder.

7. How does omnichannel selling impact order management strategy?

Omnichannel selling complicates order management — but also makes it more strategic. When customers purchase on websites, in stores, or on marketplaces, your system needs to keep pace with all of these touchpoints. A unified OMS ensures that pricing is consistent, inventory visibility is accurate, and fulfillment is synchronized across all channels, giving customers a reliable experience wherever they shop.

8. What is the role of real-time inventory visibility in reducing returns?

Customers know exactly what is available – and companies can view inventory at all warehouses – the errors are dramatically reduced. Real-time visibility also prevents overselling, stock outs, and delayed shipments. The result is less cancellations and returns, happier customers, and better profit margins. Transparency, in a nutshell, saves time and money.