For many years, the main goal of supply chains was to be as efficient as possible. Get things from point A to point B faster, cheaper, and in larger amounts. But efficiency alone is no longer enough as climate change and a lack of resources change the world economy.

It’s not enough for manufacturers to just make a lot of things; they also have to make them in a way that is good for the environment. This is where green supply chain management (GSCM) comes in — if you’ve ever wondered what is green supply chain management, it’s simply a framework that balances performance with responsibility toward the planet.

Sustainability is no longer just a “corporate initiative” as we move into 2025. It gives you an edge over the competition. Let’s look at how green supply chains are changing the rules of the game for manufacturing, from getting materials to delivering them.

What does it mean to manage a green supply chain?

Green supply chain management (GSCM) is the process of thinking about the environment at every stage of the supply chain, from getting raw materials to getting rid of products. It’s not just about cutting down on pollution. It’s about changing the way things are done to cut down on waste, save resources, and support the ideas of a circular economy. Cost is the most important thing in traditional supply chains. In a green supply chain, the focus shifts to balancing cost, efficiency, and environmental impact all at once.

That means that manufacturers think about:

- Where materials come from (sustainably or not)

- The cost of making energy

- How to make packaging and shipping better

- And how things can be reused or recycled after they have been used

It’s a full-circle way of making things, where sustainability isn’t just a box to check off.

The Change: Why Companies Are Going Green

The move towards green supply chain management has sped up a lot in the last five years.

Here’s why:

- People’s expectations have changed. Customers now want products that are good for the environment and clear about where they come from.

- Rules are getting stricter. Governments all over the world are making laws about emissions, waste, and energy stricter.

- People who invest are paying attention. ESG (Environmental, Social, and Governance) factors now affect the flow of capital and the performance of stocks.

- There aren’t enough resources. As the cost of raw materials goes up, cutting down on waste becomes not only the right thing to do, but also the smart thing to do.

Going green isn’t just “good PR” in 2025. It’s good for business.

Understanding the objectives of green supply chain management helps companies set clear sustainability benchmarks

Goals of Green Supply Chain Management

Now that we know what it is, let’s talk about the goals of green supply chain management. These are the specific things that businesses want to do.

| Objective | Description |

| 1. Reduce Carbon Footprint | Lower emissions across transportation, manufacturing, and logistics networks. |

| 2. Optimize Resource Use | Use less energy, water, and materials without compromising output. |

| 3. Encourage Sustainable Sourcing | Partner with suppliers who use renewable materials or ethical practices. |

| 4. Promote Recycling & Reuse | Design products that can be reused, refurbished, or recycled. |

| 5. Ensure Regulatory Compliance | Meet environmental laws and certifications like ISO 14001 |

| 6. Drive Long-Term Profitability | Align sustainability with cost savings through efficiency gains. |

In short, the goals of green supply chain management are to be environmentally responsible and to run a business well. These objectives of green supply chain management also ensure measurable outcomes across emissions, sourcing, and energy efficiency.

When done right, it leads to both — a cleaner planet and a more resilient business model.

The 2025 Playbook: What Green Practices Manufacturers Are Using

Manufacturers in 2025 are rewriting their playbooks with smarter, greener processes. Let’s look at how these look at different points in the supply chain.

1. Sustainable Sourcing

Businesses are working with eco-certified suppliers and checking to see if their suppliers are environmentally friendly. For example, Nike gets recycled polyester for clothes, which saves millions of litres of water every year.

2. Making things cleaner

To cut down on waste, factories are switching to renewable energy sources like solar or wind and using closed-loop water systems.

3. Packaging that is good for the environment

Packaging is getting lighter, easier to recycle, or it breaks down in nature. To cut down on paper waste, a lot of businesses now use digital labels.

4. Efficient Transportation

Route planning that is optimised, electric vehicle fleets, and shipping loads that are combined all help lower emissions during transit.

5. Logistics in the opposite direction

Instead of being thrown away, returned items are refurbished, repurposed, or recycled, which helps make things more circular. Not only do these steps help the environment, but they also save money over time.

Now that we’ve seen what companies are doing, let’s explore the benefits of green supply chain management — both environmental and financial.”

The pros of green supply chain management

Now that we’ve seen what companies are doing, let’s explore the benefits of green supply chain management — both environmental and financial.

| Benefit | Why It Matters |

| 1. Cost Efficiency | Reducing energy, materials, and waste directly cuts operational costs. |

| 2. Stronger Brand Reputation | Eco-friendly practices attract conscious consumers and investors. |

| 3. Regulatory Advantage | Compliance with environmental norms prevents fines and penalties. |

| 4. Risk Mitigation | Sustainable sourcing lowers dependency on scarce resources. |

| 5. Innovation Boost | The push for green often leads to process and product innovation. |

| 6. Employee Morale & Retention | Working for a sustainable company improves engagement and pride. |

In short, green supply chain management has many benefits that go beyond the environment. It makes businesses more competitive, profitable, and purposeful.

How Technology Helps Green Supply Chains

There is no complete sustainability strategy in 2025 that doesn’t include technology. This is how digital tools are helping businesses reach their environmental goals:

- IoT and sensors can keep track of energy use and emissions in real time.

- AI and machine learning: Predictive models make transportation routes better and cut down on idle time.

- Blockchain: Enables traceability, ensuring materials are ethically sourced.

- Digital Twins: Simulate supply chain models to test sustainability improvements before implementing them.

These innovations turn sustainability into a measurable, data-driven process — not just a corporate slogan.

A Case Study in Green Supply Chain Management: Unilever

Let’s look at a case study of green supply chain management that has set standards around the world: Unilever.

Unilever’s “Sustainable Living Plan” makes sure that environmental goals are part of every part of its supply chain.

Here’s how:

- Renewable Sourcing: 95% of palm oil used is sustainably sourced.

- Eco-Manufacturing: Over 70% of factory waste is now recycled or recovered.

- Energy Efficiency: The amount of CO₂ released per tonne of production has gone down by 70% since 2008.

- Sustainable Packaging: The company aims for 100% recyclable or reusable packaging by 2030.

The result? Unilever has achieved over €1 billion in annual cost savings from sustainable manufacturing practices. This green supply chain management case study proves that sustainability isn’t a cost center – it’s a growth driver.

Problems with using green supply chain management

Despite its clear advantages, going green isn’t always smooth. Here are some problems that manufacturers have to deal with:

- High Initial Investment: You need to put money into renewable energy and green tech right away.

- Supplier Non-Compliance: Smaller suppliers may lack sustainability infrastructure.

- Lack of Standard Metrics: Measuring environmental performance consistently can be tough.

- Resistance to Change: Employees or partners accustomed to traditional systems may hesitate.

- Complex Global Networks: Managing sustainability across multiple regions adds logistical complexity.

The good news? As ESG regulations tighten and technology becomes cheaper, these barriers are falling fast.

How Manufacturers Can Start Going Green (In 2025 and Beyond)

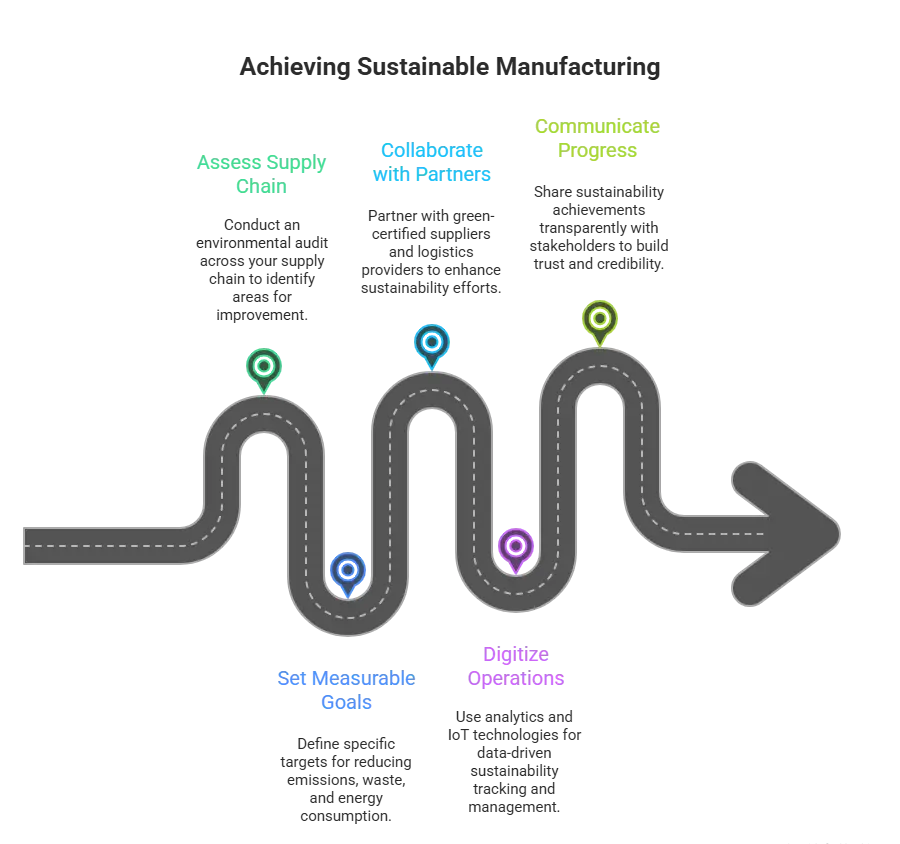

Here’s a simple plan for businesses that want to go green:

- Assess: Conduct an environmental audit across your supply chain.

- Set Measurable Goals: Define targets for emissions, waste, and energy reduction.

- Collaborate: Partner with green-certified suppliers and logistics providers.

- Digitize: Use analytics and IoT for data-driven sustainability tracking.

- Communicate: Share progress transparently with stakeholders — it builds trust.

Even small changes, like switching to LED lights, finding the best delivery routes, or using the same packaging again and again, add up over time.

The Next Step in Green Manufacturing: Future Trends

Green supply chain management will go from being a project to the norm by 2025 and beyond.

Next up:

- Net-Zero Factories: Powered entirely by renewable energy.

- Designing products in a circle: making everything with recycling in mind.

- Zero-Waste Logistics: Better routes and reusing packaging.

- Carbon Accounting Platforms: AI-based tracking of carbon footprints across supply chains.

Manufacturing will no longer have to work towards sustainability; it will just be the way it works.

Conclusion

Sustainability is no longer just a side project; it’s the plan for how manufacturing will do well in a world with limited resources. The first step is to learn what green supply chain management is — understanding its objectives and benefits is key to implementing it successfully. The next step is to put it into action, which is what makes future leaders stand out.

Every green supply chain management case study, from Unilever to Toyota, teaches us one important thing: sustainability and efficiency are not enemies; they are friends. Companies can protect the planet and make sure their success lasts by making sure their environmental goals are in line with their business strategy.

In 2025, the question isn’t whether to be eco-friendly. How fast can you do it?

FAQs:

1. What is the management of a green supply chain?

It is a way to make the supply chain more environmentally friendly at every step, from getting materials to throwing away products.

2. What are the main goals of managing a green supply chain?

Lowering emissions, cutting down on waste, making the best use of resources, making sure rules are followed, and encouraging sustainable sourcing.

3. What are the good things about managing a green supply chain?

Cost savings, a better brand image, following the rules, coming up with new ideas, and making money in the long run.

4. Can small businesses go green?

Yes. Even small, low-cost actions like reusing packaging, doing energy audits, or working with eco-friendly suppliers can make a difference.

5. What is a real-life example of green supply chain management?

One of the best examples of a global supply chain change is Unilever’s, which cut CO₂ emissions by 70% and saved more than €1 billion.

6. What role does technology play in advancing green supply chain management?

Digital technologies such as IoT, AI, blockchain can track emissions, streamline logistics, and verify sustainable sourcing – transforming environmental data into actionable insights.

7. What are the challenges to green supply chain management implementation?

Barriers include initial costs that are too high and sustainable criteria that are too difficult for suppliers to meet, as well as a lack of standard sustainability metrics. These barriers are melting quickly thanks to technology adoption and government incentives.

8. Which industries find green supply chain most useful?

Manufacturing, retail, logistics, and FMCG are the biggest beneficiaries — they cut costs, bring in eco-conscious consumers, and make their operations future-proof.