The supply chain management has transcended to being a back-end operational activity to being a strategic business imperative. The current competitive world requires organizations to wear the drivers of SCM in order to remain competitive in the market.Knowing what drives your supply chain is no longer about logistics, but making value, creating resilience, and providing outstanding customer experiences.

What Are the Drivers of SCM?

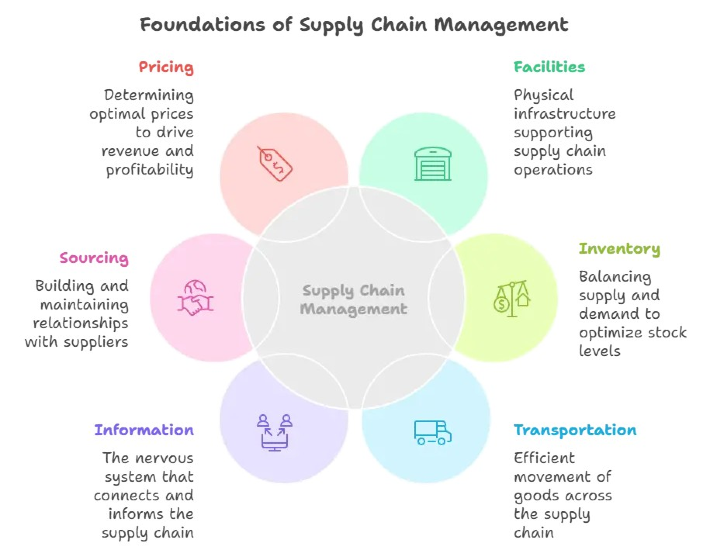

The SCM drivers are the basic elements that define the efficiency and effectiveness of a supply chain. These factors combine to achieve a smooth flow of goods, information and money between the suppliers and final consumers.

Consider them as the engine components of your supply chain vehicle. All drivers have their own role to play, but they have to co-exist to perform optimally.

Why It is Important to Know Supply Chain Drivers.

Those organisations that do not take into consideration these drivers experience:

Higher operation expenses.

Poor customer satisfaction

Inventory mismanagement

Competitive disadvantages

Revenue losses

On the other hand, those companies that maximize these drivers are enjoying better margins, short delivery time as well as solid market positions.

Key drivers of supply chain management

1. Facilities: Support of Your Supply Chain.

Facilities are the physical premises at which products are produced, stored or sold. These are the factories, warehouses, distribution centers and the retail stores.

Strategic Considerations:

Location optimization lowers the transportation expenses.

Capacity planning provides the fulfillment of demand.

Flexibility enables a rapid response in the market.

The efficiency is enhanced with the integration of technology.

An example of a practical supply chain would include the strategically located fulfillment centers of Amazon towards major metropolitan centers where it can deliver the product within a day or the following day.

2. Inventory: Supply and Demand Balancing Act.

The inventory is the buffer between supply and demand. It is among the most apparent SCM driving forces that affect the costs and level of customer service directly.

Key Inventory Decisions:

Normal demand cycle inventory.

Demand variation safety stock.

Predictable fluctuations to use seasonal inventory.

Inventory of goods in transit (pipes).

Smart inventory management implies that the right products are in the right place and at the right time and not too many holding costs.

3. Transportation: Getting Goods Moving.

Transportation defines the movement of products in the supply chain destinations. This driver influences greatly the cost and responsiveness.

Transportation Modes.

Speedy and urgent air shipment.

Cost effective bulk transport by sea.

Heavy ground rail.

Flexible and accessible trucking.

Businesses need to trade off speed and cost when choosing the means of transportation. An example of a supply chain is the use of air freight of new fashion items by Zara, even though it is more expensive, to have trend-responsive inventory.

High-Performance Drivers to Build.

4. Information: SCM Nervous System.

Perhaps the most radical of all digital age drivers of SCM is information flow. On-the-fly data visibility is an ability to make decisions proactively.

Information Systems Enable:

The accuracy of demand forecasting.

Inventory management and optimization.

Supplier collaboration

Customer order management

Performance analytics

The lack of correct information results in blind operation of the supply chains and thus inefficiencies and errors.

5. Sourcing: Developing the Right Relationships.

Sourcing decisions identify the one who undertakes supply chain activities. The choice between the in-house operations and outsourcing has to be made by the organizations.

Sourcing Strategies:

Single sourcing to be simple.

Several sourcing as a risk mitigation measure.

Near-sourcing to be on time.

International sourcing of cost benefits.

The major forces of supply chain management are the ability to choose the partners according to your strategic goals and business needs.

6. Pricing: Revenue/ Profitability Driver.

Pricing strategies influence the amount of payment that customers pay to products and services. This driver is able to balance revenue generation as well as competitiveness in the market.

Pricing Approaches:

Fixed pricing for stability

Market responsiveness, which is a dynamic pricing.

Pricing of services menu.

Pricing of customer segments.

This needs to be priced effectively through understanding the cost structures, customer value perception and competitive dynamics.

The Effects of these Drivers on Supply Chain Performance.

The supply chain performance drivers interact with each other. It is hardly possible to optimize an individual driver to achieve desired results.

The Tradeoff between Responsiveness and Efficiency.

All supply chains have this basic tension:

Responsive Supply Chains:

Higher inventory levels

Swifter means of transport.

Several plants near the customers.

Premium pricing

Efficient Supply Chains:

Lean inventory

Cost-effective transportation

Centralized facilities

Competitive pricing

It is important to know where your business should fit on this spectrum in order to be successful.

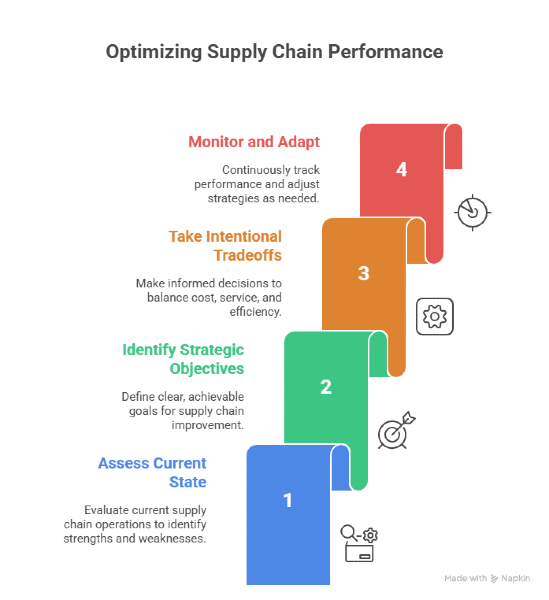

How to make the most of the Drivers of Supply Chain Performance in Your Business.

Step 1: Assess Current State

Start by assessing the current performance by each driver in your supply chain. Determine bottlenecks, inefficiencies and lack of fit with business strategy.

Step 2: Identify Strategic Objectives.

Identify your competitive advantage of either cost leadership, differentiation or focus strategy. This positioning should be supported by your supply chain drivers.

Step 3: Take Intentional Tradeoffs.

You can not maximize everything at the same time. Decide on which drivers to maximize out of your strategic priorities.

Step 4: Monitor and Adapt

There should be continuous monitoring of the drivers of supply chain performance. Set KPIs and performance of the individual drivers and review it often.

Application in the Real World: Industry Supply chain Examples.

E-commerce Success Story

Think of the success experienced by e-commerce sites using the SCM drivers:

Several fulfillment centers (facilities) close to cities.

Complex algorithms (information) on inventory location.

Combined cost-speed transportation plans.

Dynamic pricing in reaction to the demand and competition.

Strategic alliances (sourcing) with 3rd parties logistics providers.

Manufacturing Excellence

Key manufacturers pay attention to other drivers:

Economies of scale production centres.

Just-in-time inventory in order to reduce carrying costs.

Quality and reliability Supplier relations are over the long term.

Economy transport in bulk.

End-to-end visibility ERP systems.

Issues that are usually encountered in the management of SCM Drivers.

Challenge 1: Data Silos

Most organizations are faced with a problem of disparate information on various systems, which inhibits visibility and decision making.

Challenge 2: Unstable Demand.

The changes in the market are not predictable, thus making it hard to optimise inventory and facilities.

Challenge 3: Cost Pressures

The challenge of maintaining service level and cost reduction is a continuous challenge to most supply chains.

Dilemma 4: Complexity of Globalization.

Regulatory, cultural and logistical complexities arise when managing the drivers of supply chain management across the borders.

Challenge 5: Techno in Action.

Old systems are usually hard to integrate with new supply chain technologies in a manner that gives a strain in their operations.

Trends in the Future that can influence SCM Drivers.

Sustainability Imperative

The issue of the environment is transforming the approach used by the organization towards every supply chain driver. Medical facilities that are green, carbon-neutral transportation, and principles of a circular economy become part of the norm.

Digital Transformation

New technologies keep transforming the SCM drivers:

Self-driving cars transforming transport.

3D printing interfering with facilities and inventory.

AI optimization of all decision points.

Simulation and testing possible through digital twins.

Customer-Centricity

Customers now require faster delivery, increased customization and total transparency- compelling organizations to re-align their supply chain drivers accordingly.

Conclusion

The art of SCM drivers is no longer a luxury of business ventures that are aimed at achieving sustainable competitive advantage. The six basic drivers of these include: facilities, inventory, transportation, information, sourcing, and pricing, all of which combine in order to measure the effectiveness of your supply chain.

You can make a supply chain yourself or you can streamline an existing supply chain but in any case, it will speed up your success when you work with seasoned professionals. Qodenext focuses on assisting companies to change the way their supply chain functions by planning how to get the most out of every driver and gain a competitive edge.

You know, there is no universal way. The most suitable arrangement of supply chain drivers will be contingent on your industry, clientele, as well as, business strategy. Begin by evaluating your current position, set a goal of where you just want to be tomorrow and then, methodically, approach that vision.

Frequently Asked Questions

What is the Bullwhip Effect and how can we minimize it?

The Bullwhip Effect occurs when even the slightest change in consumer demand causes increasingly large swings in the inventory quantities and orders as they cascade up the supply chain. This results in surpluses, lack of supply and inefficiency.

Ways to lessen it include:

– Improving the accuracy of demand predictability.

– Exchange of information with all partners on a regular basis.

– Reducing lead times and reducing batch sizes.

2. How does logistics differ with supply chain management?

Logistics is the study of transport, storage and movement of goods between the source and the ultimate user.

Supply Chain Management (SCM) is larger in that it encompasses sourcing, manufacturing, logistics, information exchange and coordination of all the stakeholders.

To the point, logistics is an element of SCM, which is in charge of the entire end-to-end process.

3. What is demand forecasting and what is the need of it in SCM?

Demand forecasting uses previous sales information, trends, and analysis tools to estimate future customer needs.

It helps companies to calculate inventory, production and buying plans.

Precise forecasts reduce costs, avoid stockouts and increase customer satisfaction, which is essential in SCM.

4. What are the impacts of such technologies as AI, IoT, and blockchain on contemporary supply chains?

Technology enhances transparency, speed, and decision making throughout the chain of supply.

– AI: forecasts demand and automates the planning process.

– IoT: offers real-time asset and shipping monitoring.

– Blockchain: provides secure and tamper-proof transactions records.

These tools enhance efficiency, traceability and trustworthiness throughout the network.

5. What do you do to assess and eliminate supply chain risks?

The first step is to identify potential risks such as supplier disruptions, transportation delays, geopolitical factors, etc.

Assess the risk through a risk matrix.

Mitigation tactics include:

– Distributing the supplier base.

– Holding safety stock

– Enhancing the contracts and using the real-time monitoring solutions.

6. What is the difference between push and pull models of supply-chain?

– Push model: the production is forecast driven and products are pushed into the market.

– Pull model: manufacturing and distribution responds to the real customer orders.

Push is most appropriate when demand is stable and predictable and pull when it can be much more customized and agile.

7. What would you do in case of a supply-chain failure, e.g. when one of your suppliers fails to deliver?

– Call the supplier at once in order to explain the situation.

– Have other suppliers or alternative materials available should there be a possibility.

– Re-route deliveries or change manufacturing plans.

– Examine the terms of the contract and revise risk-management plans to prevent such problems going forward.

8. What are the major sustainability issues in the supply-chain management?

Sustainability in SCM is expected to reduce environmental footprint, guarantee ethical sourcing as well as waste.

Key focus areas:

– Renewable or low impact materials.

– Reduction of carbon emission in transportation and warehousing.

– Ensuring fair labor conditions in the supplier network.

Sustainability will increase brand recognition and meet regulatory and consumer expectations.