In recent years, artificial intelligence (AI) has emerged as a transformative force across various sectors, and the manufacturing industry is no exception. The integration of AI in the manufacturing industry is revolutionising production processes, enhancing efficiency, and setting the stage for a new era of industrial innovation. From predictive maintenance to smart automation, AI is reshaping how manufacturers design, operate, and optimise their operations.

The Evolution of Manufacturing with AI

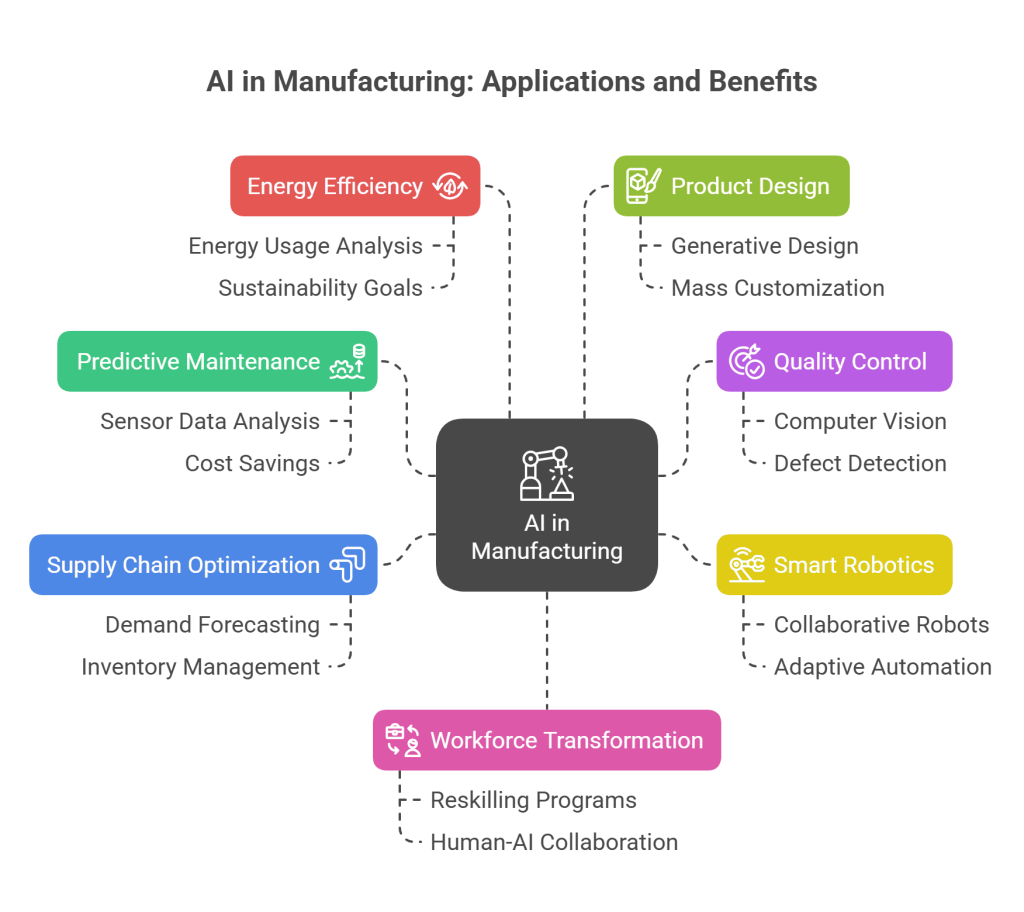

Traditionally, manufacturing has relied on manual labor, mechanical equipment, and static processes. While automation brought significant improvements, it often lacked the intelligence to adapt, predict, and self-correct. That’s where AI in the manufacturing industry steps in. By combining machine learning, computer vision, and advanced analytics, AI systems can now process vast amounts of data, identify patterns, and make informed decisions in real time.

This shift from reactive to proactive manufacturing marks a fundamental change. Factories are no longer just sites of production — they are becoming intelligent ecosystems that adapt to demand, reduce waste, and ensure consistent product quality.

1. Predictive Maintenance: Minimising Downtime

One of the most impactful applications of AI in the manufacturing industry is predictive maintenance. In traditional setups, machinery is either repaired after failure or maintained on a fixed schedule. Both approaches have drawbacks — unexpected failures disrupt production, and routine maintenance can be unnecessarily costly.

AI algorithms analyse sensor data to predict when equipment is likely to fail, allowing for maintenance only when necessary. This not only prevents unplanned downtime but also extends the life of machinery and saves on maintenance costs. With AI in manufacturing, companies are transitioning from reactive to predictive asset management.

2. Quality Control with Computer Vision – Application of AI

Ensuring consistent product quality is a key priority in manufacturing. AI-powered computer vision systems are now capable of inspecting products at a level of precision that surpasses human capabilities. These systems detect defects in real-time, analyse root causes, and even suggest adjustments to machinery or processes.

Using AI-powered manufacturing for quality control reduces waste, increases yield, and builds customer trust. It also provides insights into production anomalies that would otherwise go unnoticed.

3. Smart Robotics and Automation

Robots have long been used in manufacturing, but AI is taking automation to the next level. Unlike traditional robots that follow fixed instructions, AI-driven robots can learn, adapt, and make decisions based on their environment. This makes them ideal for tasks requiring flexibility, such as handling varied product types or working alongside human employees.

Collaborative robots (cobots) are a growing trend, and they rely heavily on AI to operate safely and efficiently. The integration of AI in robotics enables smarter, more responsive automation across the factory floor.

4. Supply Chain Optimisation

AI in the manufacturing industry doesn’t stop at the factory gate. It also plays a crucial role in supply chain management. By analyzing data from suppliers, production lines, and customer demand, AI can forecast needs, optimize inventory levels, and identify potential disruptions before they occur.

This enhanced visibility helps manufacturers make better decisions, reduce holding costs, and improve customer satisfaction. In an age where supply chain resilience is paramount, AI provides the intelligence needed to stay ahead.

5. Energy Efficiency and Sustainability

Sustainability is becoming a major concern in the manufacturing sector. AI can help manufacturers reduce energy consumption and minimize their environmental impact. By analyzing energy usage patterns and optimizing machine performance, AI systems identify areas for improvement and implement changes automatically.

With growing pressure to meet environmental standards, the use of AI-based software is proving to be a powerful tool for achieving sustainability goals while also lowering operational costs.

6. Product Design and Customisation

AI is also influencing how products are designed and customised. Generative design, powered by AI, allows engineers to input design goals and constraints, and the system generates multiple design options optimised for performance and cost.

In addition, AI in the manufacturing industry supports mass customization by enabling dynamic production lines that can adjust to customer-specific requirements without sacrificing efficiency. This flexibility is a major advantage in today’s customer-centric market.

7. Workforce Transformation

While there’s concern about AI replacing human jobs, the reality is more nuanced. AI is transforming the workforce by taking over repetitive and dangerous tasks, allowing human workers to focus on higher-value roles such as system supervision, data analysis, and strategic planning.

Reskilling and upskilling the workforce is key to this transition. Manufacturers that invest in training programs and human-AI collaboration strategies are positioning themselves for long-term success.

Challenges of Adopting Manufacturing AI

Despite its benefits, implementing AI tools in manufacturing is not without challenges. These include:

- High initial investment in technology and infrastructure

- Data integration issues across legacy systems

- Cybersecurity risks with interconnected systems

- Skill gaps in the existing workforce

- Change resistance at organisational levels

To overcome these challenges, manufacturers must approach AI adoption with a clear strategy, involving all stakeholders and focusing on measurable ROI.

The Future Outlook

The future of AI in the manufacturing industry is promising. As AI technologies mature and become more accessible, we can expect even greater levels of automation, efficiency, and innovation. From autonomous factories to self-healing machines, the possibilities are endless.

Governments and industry bodies are also recognizing the importance of AI in manufacturing and are investing in research, policy frameworks, and collaboration platforms to support this transition.

For businesses that embrace AI early, the competitive advantages will be substantial, from faster production cycles to smarter decision-making and greater customer satisfaction.

FAQs on AI in the Manufacturing Industry

1. What is AI in the manufacturing industry?

AI manufacturing refers to the application of artificial intelligence technologies such as machine learning, computer vision, and robotics to improve production processes, quality control, and supply chain operations.

2. How does AI improve manufacturing efficiency?

AI improves efficiency by enabling predictive maintenance, automating repetitive tasks, optimising supply chains, reducing waste, and enhancing product quality.

3. Will AI replace human workers in manufacturing?

While AI may automate certain tasks, it is more likely to augment human roles. The focus will shift to managing AI systems, interpreting data, and strategic decision-making.

4. Is AI in manufacturing expensive to implement?

Initial investments can be high, but the long-term benefits in terms of efficiency, cost savings, and reduced downtime often outweigh the costs. Modular and scalable AI solutions are also becoming more affordable.

5. How can small manufacturers adopt AI?

Small manufacturers can start by integrating AI tools in specific areas such as predictive maintenance or inventory management. Cloud-based platforms and industry partnerships can lower the barrier to entry.

6. What are the risks of using AI in manufacturing?

Potential risks include data breaches, reliance on inaccurate algorithms, and workforce displacement. These can be mitigated through strong data governance, regular audits, and workforce training.

Conclusion

AI in the manufacturing industry is more than a trend; it’s a game-changer. It’s driving a smarter, safer, and more sustainable industrial future. From reducing operational inefficiencies to enabling real-time decision-making, the benefits are clear and far-reaching.

As the industry continues to evolve, the role of AI will only grow stronger. For manufacturers willing to embrace the shift, the future is not just automated, it’s intelligent. Contact Qodenext to take the first step towards an automated traceability system.