Walk into any modern warehouse today, and you’ll find more than just shelves stacked with goods.

You’ll see dashboards tracking inventory movements, sensors capturing real-time data, and software making split-second decisions. This shift isn’t a coincidence – it’s the rise of Real-Time Analytics in Warehouse Operations.

Gone are the days when warehouse managers had to rely on yesterday’s reports to make today’s decisions. Now, they have access to operational analytics that offer instant insights into everything from worker productivity to shipment accuracy. The result? Warehouses that are faster, leaner, and smarter.

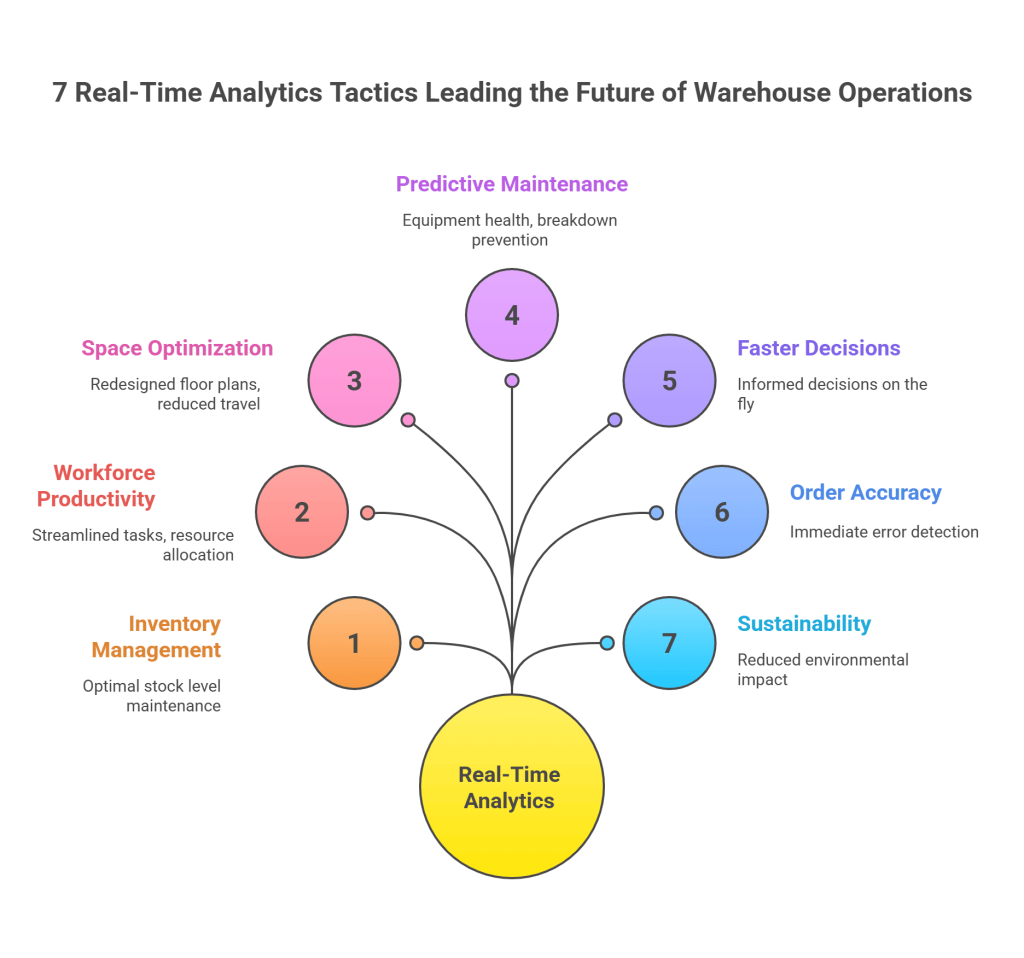

Let’s break down how exactly warehouse analytics is reshaping the way logistics, retail, and manufacturing companies manage their warehousing needs.

1. Smarter Inventory Management

Inventory issues are among the most common pain points in Warehouse Operations. Too much stock? You’re losing money on storage. Too little? You risk delayed orders and unhappy customers.

- Real-Time Analytics helps managers maintain optimal stock levels by analyzing incoming data on sales, returns, supplier lead times, and demand trends. For example, Amazon uses real-time data models to predict product demand and automatically restock warehouses accordingly.

- Warehouse analytics tools also flag inventory anomalies in real time, preventing shrinkage and misplacement. No more waiting until month-end to realize a SKU has gone missing.

Now that we’ve looked at inventory, let’s move on to the people powering the warehouse – the workforce.

2. Boosting Workforce Productivity

Your workers are the backbone of any warehouse. But without visibility into their daily tasks and movement patterns, it’s hard to optimize workflows.

- With operational analytics, managers can track picking speeds, identify idle times, and even monitor which areas of the warehouse are causing delays. DHL, for instance, uses wearable tech and analytics platforms to monitor worker efficiency and identify training needs.

- Real-Time Analytics doesn’t just increase productivity -it also improves worker satisfaction by streamlining repetitive tasks and improving resource allocation.

Since we’re talking about movement and flow, let’s explore how this technology improves space utilization.

3. Optimizing Warehouse Layout and Space

Inefficient layouts can make even the most advanced warehouse underperform. Think long walking distances, congested aisles, or poor bin placement.

- By using warehouse analytics, companies can analyze foot traffic and item retrieval patterns to redesign their floor plans. Walmart uses real-time heatmaps and data modeling to create optimized picking paths, reducing the average distance traveled per order.

These insights not only improve operational speed but also reduce labor costs and safety risks.

Now that we’ve tackled the physical layout, let’s shift gears to talk about equipment and machinery.

4. Predictive Maintenance and Equipment Monitoring

Downtime due to machine failure can grind Warehouse Operations to a halt.

- But Real-Time Analytics allows for predictive maintenance – where equipment health is continuously monitored, and issues are flagged before breakdowns occur.

- This is particularly valuable in automated warehouses. For example, Ocado, the UK-based online grocer, uses real-time monitoring of its robotic systems to schedule repairs before performance drops.

The result? Fewer disruptions, longer equipment lifespans, and better ROI.

Now that we’ve seen how machines are managed, let’s look at how real-time data supports better decision-making overall.

5. Enabling Faster and Smarter Decision-Making

One of the most powerful benefits of Real-Time Analytics is the ability to make informed decisions on the fly.

Whether it’s rerouting a delayed shipment, adjusting labor during peak hours, or reallocating storage space, having up-to-the-minute data enables agility.

- Operational analytics platforms often include alert systems that notify managers the moment something goes off-track. Companies like Target use real-time dashboards across their distribution centers to monitor KPIs and react swiftly to demand changes or bottlenecks.

Since we’re on the subject of responsiveness, it’s a good time to explore how analytics impact order accuracy.

6. Improving Order Accuracy and Customer Satisfaction

Order accuracy is crucial in keeping customers happy and reducing return rates.

- With Real-Time Analytics, warehouses can immediately catch errors in picking, packing, and shipping. Some systems use barcode scanners and machine learning to validate each stage of the process in real-time.

Zara, for instance, uses real-time scanning and automated sorting to ensure accurate dispatches from its warehouses, which contributes to its fast fashion model and high customer satisfaction.

Let’s now explore another area where real-time data makes a big impact: sustainability.

7. Driving Sustainability Through Data

Sustainability is no longer a nice-to-have; it’s a must. And warehouse analytics can help businesses track and reduce their environmental impact.

- Real-time systems can monitor energy consumption, waste levels, and packaging usage. For example, Schneider Electric integrates real-time energy monitoring with its warehouse systems to reduce electricity consumption and carbon footprint.

These insights allow companies to set measurable sustainability goals and report transparently to stakeholders.

So what does all of this tell us about the future of warehouses?

Building the Warehouse of the Future

Modern Warehouse Operations are evolving into dynamic ecosystems powered by data. From inventory to people, layout to equipment, and decision-making to sustainability, Real-Time Analytics is no longer optional.

The real question for companies is: Are you using your data to drive action? Because if not, someone else in your market already is.

FAQs: 7 Real-Time Analytics Tactics Leading the Future of Warehouse Operations

1. What types of data are used in warehouse analytics?

Warehouse analytics platforms pull data from inventory systems, sensors, barcodes, RFID tags, employee wearables, and more to generate insights.

2. Can small businesses benefit from operational analytics?

Absolutely. Even small warehouses can use affordable cloud-based tools to track performance and improve efficiency.

3. How secure is real-time data in warehouse operations?

Most modern platforms use end-to-end encryption and strict access controls to ensure data security.

4. What KPIs can be tracked using real-time analytics?

Common KPIs include order accuracy, pick rate, labor utilization, stock turnover, and equipment uptime.

5. How soon can companies expect ROI from these systems?

Many businesses see measurable improvements within 6 to 12 months, especially in cost savings and productivity.

Conclusion

In a world where speed and accuracy define competitive advantage, real-time analytics is no longer a nice-to-have—it’s essential. From streamlining warehouse operations to reducing errors and improving fulfillment speed, data-driven decision-making is rewriting the rules of logistics. Whether you’re managing a small distribution center or running a global supply chain, embracing warehouse analytics means staying ahead of demand, not just keeping up with it. As more businesses follow in the footsteps of giants like Amazon and DHL, the message is clear: the future of warehousing is intelligent, real-time, and relentlessly efficient.