Companies have a significant role to play in cutting global greenhouse gas emissions. While many are already transforming their supply chains with electric vehicles and cleaner fuels for transporting goods, there’s even more potential for impact.

The facilities where businesses store or manufacture their products present substantial opportunities for going green. The World Green Business Council highlights that the building sector holds the highest potential for reducing greenhouse gas emissions. Discover in this blog how to create a sustainable warehouse and why it matters.

Sustainable Warehouse Technologies and Products

Modern automation is at the heart of sustainable warehousing. Implementing various types of warehouse automation-from automated storage and retrieval systems to collaborative robots and voice-picking-can drastically cut energy consumption, minimize human error, and increase throughput. Automation also enables precise inventory control, which reduces waste and unnecessary movement. Once warehouses assess their operations to identify environmentally friendly logistics solutions, several green warehousing products can enhance sustainability:

1. Warehouse Management System (WMS)

A WMS helps in the efficient control of stores, distributors, and warehouses, including organizing shipment and transportation. Sustainability is achieved with green WMS as it enables warehouses to control the right stock supply to avoid congested or empty shelves. Streamlining your inbound process with best practices such as those outlined in how to improve warehouse receiving process ensures less idle time for trucks and reduces emissions. For containerized shipments, mastering warehouse container unloading in 5 easy steps not only improves safety and efficiency but also helps minimize product damage and waste.

2. Order-Picking Technology

Automation or digitization of order-picking processes enhances accuracy and speeds up warehouse operations, while also reducing paper consumption.

3. Bar Coding and Radio Frequency Identification (RFID)

These technologies cut down on paper usage by improving process efficiency and increasing the visibility of goods throughout the supply chain.

Additional sustainable products include skylights for natural lighting, ceiling fans for temperature control, energy-efficient lighting fixtures, green building materials, and improved insulation. Eco-friendly warehouses also focus on waste reduction, a fundamental aspect of sustainable business practices.

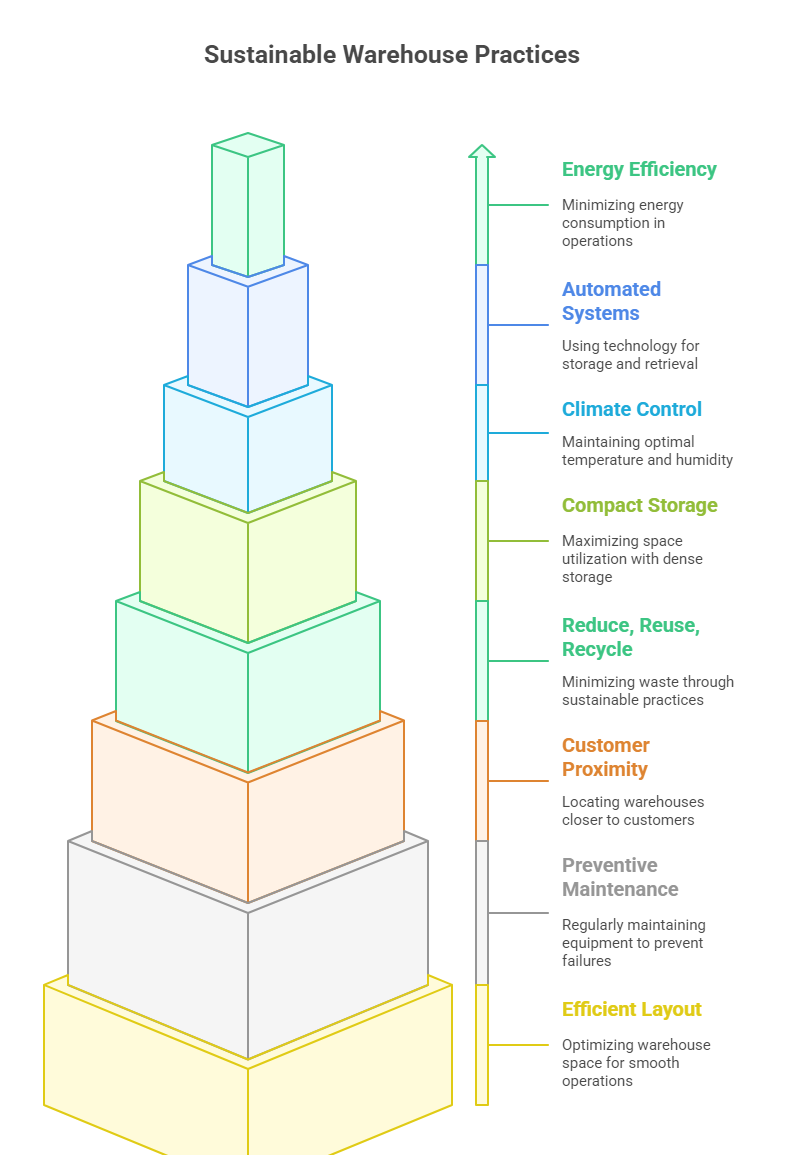

8 Practices for a Sustainable Warehouse

To reduce the environmental impact of logistics activities and promote sustainability in warehousing, companies can adopt these eight practices:

1. Energy Efficiency

Enhancing energy efficiency involves leveraging natural light and installing energy-efficient lighting solutions. Options include skylights, solar panels, and sensors. Implementing energy management systems can optimize power usage, such as shutting down machines when not in use. Investing in energy-efficient lighting, HVAC, and equipment is crucial. For specialized needs, custom built-to-suit warehouses allow you to design spaces with sustainability in mind, from solar panels to natural ventilation.

These strategies help businesses reduce their reliance on fossil fuels and lower their carbon emissions.

2. Automated Storage Systems

Automation is increasingly popular. The 2021 MHI Annual Industry Report reveals that 43% of businesses invested $5-10 million in robotics and automation due to the coronavirus pandemic, with 53% planning further investment.

Consider shared warehouse space solutions to lower your facility’s carbon footprint and operational costs. When inventory surges, overflow warehouse storage can prevent congestion and keep your processes running smoothly without unnecessary expansions.

3. Sustainable Climate Control

Air conditioning, especially in cold and freezer rooms, consumes a lot of energy. Efficient climate control involves addressing the challenges posed by large warehouses with high ceilings and multiple openings.

One effective solution is constructing warehouses with insulating materials, like sandwich panels, to reduce temperature transfer to the outside.

4. Compact Storage Systems

High-density storage systems are key to sustainable warehousing. These systems utilize available surface area to store more products. In climate-controlled environments, compact solutions lower energy consumption per pallet.

High-density systems include various options such as drive-in drive-thru pallet racks, pallet flow racks, push-back racks, and the Pallet Shuttle system. The choice depends on space availability and flow requirements.

5. Reduce, Reuse, Recycle

The US Environmental Protection Agency reported that in 2018, 14.5 million tons of plastic containers and packaging were generated, about 5.0% of municipal solid waste (MSW).

In eco-friendly warehouses, materials used daily are collected separately for recycling. With growing awareness of recycling, separating and recycling plastic, paper, and glass waste is becoming more common in sustainable warehouses.

6. Bring the Warehouse Closer to the Customer

Locating logistics facilities near customers reduces transportation needs, thereby cutting pollution and enhancing sustainability. One approach is setting up micro-fulfilment centres—small logistics facilities near major cities—shortening delivery distances and minimizing environmental impact while speeding up order fulfilment.

7. Preventive Maintenance

Implementing preventive maintenance can avert breakdowns and facilitate quick decisions in case of machine failures. The preventive maintenance market is projected to grow by 25.2% from 2020 to 2025, with technology like AI and IoT devices providing real-time warehouse data.

Preventive maintenance helps anticipate and prevent malfunctions, improving safety and sustainability in logistics facilities.

8. Efficient Layout

Optimizing storage space is crucial for enhancing warehouse throughput. This begins with refining the warehouse layout and selecting the most suitable storage system.

Warehouse simulation software is highly effective, creating virtual models of logistics facilities to test and analyze performance under various conditions, such as increased order volumes.

Goals of Green Warehousing

Sustainable logistics aims to reduce environmental costs, resource waste, and business risks, moving the world towards a green economy. By adopting a strategic approach to supply chain sustainability, companies can achieve many green goals that not only benefit the environment but also improve operational efficiency and corporate reputation. Green warehousing, for example, focuses on minimizing ecological footprints by implementing energy-efficient lighting and heating systems, using renewable energy sources like solar and wind, and employing sustainable construction materials. Waste reduction programs and recycling initiatives further contribute to lowering environmental impact while optimizing resource use. Additionally, integrating advanced technologies such as automation and AI-driven order routing can significantly reduce emissions and energy consumption, making warehouses more sustainable and cost-effective.

The Future of Sustainable Warehouse

The Future of sustainable warehousing industry continues to evolve rapidly, driven by technological advancements and increasing environmental awareness. Green warehouses, whether newly constructed or retrofitted, are setting new benchmarks for energy efficiency, waste reduction, and resource conservation. Innovations such as smart energy management systems, IoT-enabled sensors, and renewable energy integration are becoming standard practices, allowing warehouses to optimize energy consumption and reduce carbon footprints. Additionally, the adoption of circular economy principles such as reusing packaging materials and minimizing waste further enhances sustainability efforts. As these practices gain traction, they inspire global changes in warehouse operations, encouraging industries worldwide to prioritize sustainability while maintaining high levels of productivity and cost-effectiveness. This ongoing transformation promises a future where warehousing not only supports economic growth but also contributes positively to environmental stewardship.

Projected Features of New Green Warehouses

New green warehouses emphasize efficiency and sustainability. Key features include:

- Recycling areas

- Solar panels or other power-generating systems

- Drought-tolerant plants

- Green building practices

- Skylights

- Climate-appropriate roofs and walls

- Low-emitting paints

- Energy-efficient lighting

- Regionally sourced building materials.

FAQ: Sustainable Warehouse: Is It Possible?

1. Can I make a sustainable warehouse on a budget?

Yes, you can create it by implementing cost-effective measures like energy-efficient lighting, water-saving fixtures, and using recycled materials.

2. What kind of designs are good for a sustainable warehouse?

Designs that maximize natural light, use energy-efficient materials and incorporate renewable energy sources are ideal. Features like skylights, green roofs, and good insulation enhance sustainability.

3. Is a sustainable warehouse costly to manage?

Initially, it might have higher setup costs, but long-term savings on energy and maintenance can offset these expenses, making it cost-effective over time.

4. What are the most significant technology trends shaping sustainable warehouses in 2025?

The most impactful trends include the integration of advanced artificial intelligence (AI) and machine learning for predictive maintenance, inventory optimization, and real-time demand forecasting. Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) are enhancing efficiency and safety by handling repetitive tasks and collaborating with human workers. Additionally, Internet of Things (IoT) solutions are enabling real-time asset tracking and environmental monitoring, while sustainable automation technologies are reducing energy consumption and carbon footprints.

5. How do AI and machine learning improve warehouse sustainability?

AI and machine learning analyze large volumes of data to optimize inventory levels, predict equipment maintenance needs, and streamline routing and picking strategies. These technologies help warehouses reduce waste, avoid overstocking, and minimize energy usage by aligning resources more closely with demand. As a result, warehouses can operate more efficiently, reduce costs, and lower their environmental impact.

6. What role do robotics play in sustainable warehouse operations?

Robotics, including AMRs and robotic arms, automate repetitive and physically demanding tasks, increasing operational speed and accuracy. By taking over such tasks, robots free up human workers for higher-value activities and help maintain continuous, energy-efficient operations. Modern robotic systems are also modular and scalable, allowing warehouses to adapt quickly to changing demands while maintaining sustainability goals.

Conclusion

A sustainable warehouse is not only feasible but also beneficial for both the environment and your bottom line. By adopting energy-efficient technologies, smart designs, and sustainable practices, warehouses can significantly reduce their carbon footprint and operational costs.

Embracing these green strategies helps businesses align with global sustainability goals while enhancing their competitive edge. For tailored solutions and support in implementing these practices, consider partnering with Qodenext.

Our expertise in optimizing warehouse operations can guide you in creating an eco-friendly, efficient warehouse that meets your sustainability goals!