You can have the best product in the world, but without a strong supply chain, your business won’t scale. It’s as simple as that.

Whether you’re building a D2C brand, running a tech-driven startup, or managing a growing retail business, understanding the fundamentals of supply chain management is no longer optional.

It’s the invisible engine that keeps your business running. The smoother your supply chain, the faster and more cost-effectively you can deliver to customers.

In this blog, we’ll break down the supply chain fundamentals in a way that makes sense for entrepreneurs, with real-world examples, relatable explanations, and zero jargon overload.

What Is a Supply Chain, Really?

Let’s start with the basics. A supply chain is the journey a product takes from raw material to your customer’s hands. This includes sourcing, production, inventory, warehousing, transportation, and delivery.

Think of it as a relay race where every runner (supplier, manufacturer, warehouse, distributor) needs to pass the baton efficiently. If one fumbles, the whole team suffers.

Amazon, for instance, has built one of the most efficient supply chains in the world by owning nearly every part of the chain – from fulfillment centers to its own delivery network. That level of control helps them offer same-day delivery in many locations.

Now that we’ve defined it, let’s dig into the individual pieces that make it work.

Key Components of Supply Chain Management

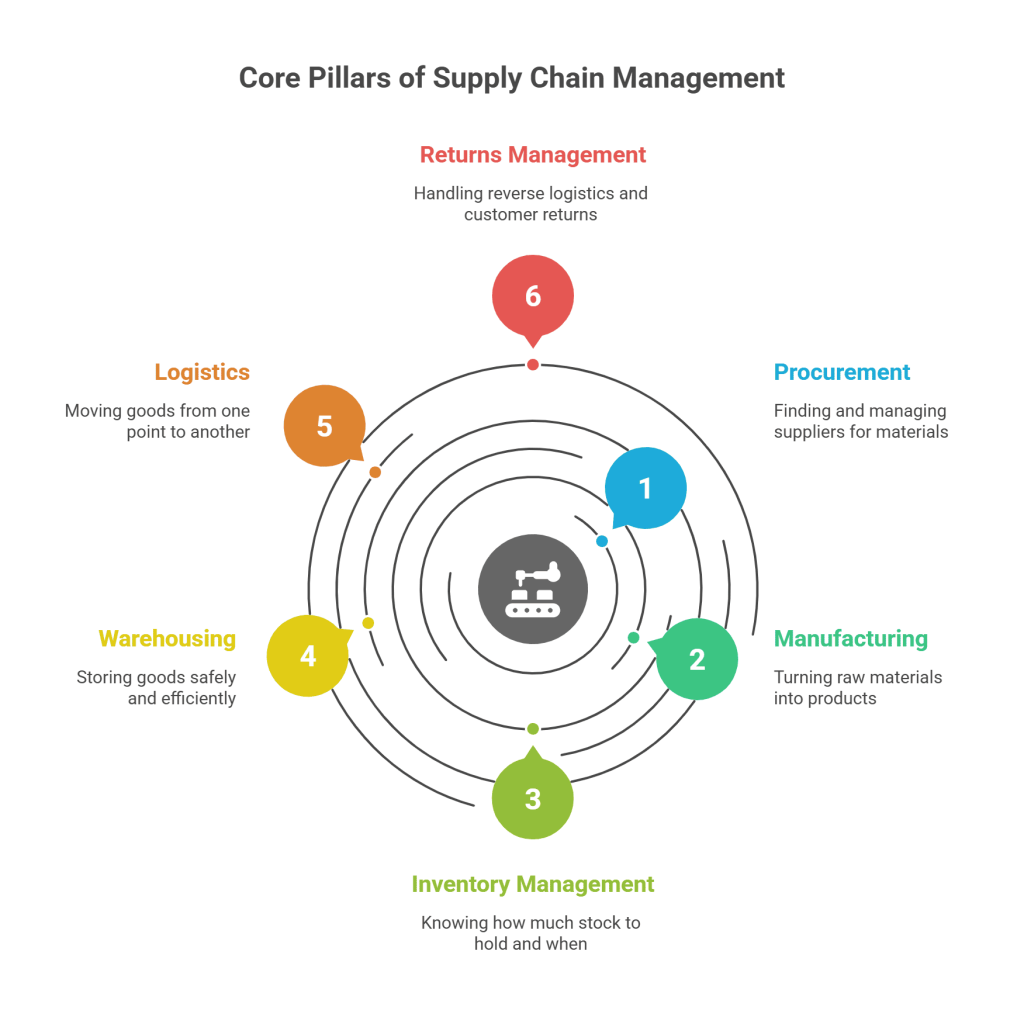

Understanding the basics of supply chain management means knowing its core pillars. Here are the must-know components:

- Procurement: Finding and managing suppliers for raw materials or finished goods.

- Manufacturing: Turning raw materials into a product.

- Inventory Management: Knowing how much stock to hold and when.

- Warehousing: Storing goods safely and efficiently.

- Logistics: Moving goods from one point to another.

- Returns Management: Handling reverse logistics, exchanges, and customer returns.

Nike excels at supply chain orchestration by closely collaborating with manufacturers and maintaining tight control over inventory and logistics. This agility helped them quickly shift inventory during the pandemic.

So we’ve covered the pieces. Next, let’s talk about how they all work together.

The Flow of a Supply Chain

At its core, the supply chain basics are about flow – product flow, information flow, and cash flow.

- Product Flow: Movement of goods from supplier to customer.

- Information Flow: Data shared between partners (orders, forecasts, inventory).

- Cash Flow: Payments made to suppliers and received from customers.

The trick is to keep all three flowing smoothly. If your product is delayed, your info is inaccurate, or your cash gets stuck, your business will feel it.

Walmart’s supply chain is a masterclass in flow. They use real-time data from POS systems to replenish inventory and negotiate better with suppliers, ensuring stores are rarely out of stock.

With the flow established, let’s now turn to strategy.

Strategic Supply Chain Decisions

Smart supply chain choices can make or break a business. Here are some strategic decisions every entrepreneur should consider:

- Make vs. Buy: Should you manufacture in-house or outsource?

- Local vs. Global Sourcing: Cheaper doesn’t always mean better.

- Centralized vs. Decentralized Warehousing: Depends on your market.

Tesla, for example, builds some of its parts in-house to ensure quality and reduce dependency on third parties. That decision paid off during the chip shortage, giving Tesla an edge over competitors.

Strategy is important, but it needs support. Let’s move on to the tech tools that help supply chains stay strong.

The Role of Technology in Supply Chains

Today, tech is at the heart of the fundamentals of logistics and supply chain management. You can’t run a modern supply chain with spreadsheets alone.

Key technologies include:

- ERP systems: For end-to-end visibility

- WMS (Warehouse Management Systems): For real-time inventory

- TMS (Transportation Management Systems): For route and freight optimization

- AI and Predictive Analytics: To forecast demand and detect disruptions

Zara uses data from stores to rapidly adjust production runs, ensuring they only make what customers want. That agility gives them a competitive edge in the fast fashion world.

Inventory Management: The Balancing Act

One of the biggest headaches for entrepreneurs is Inventory.

Too much = cash tied up and risk of obsolescence

Too little = stockouts and angry customers.

Understanding the basics supply chain means grasping these key inventory metrics:

- Safety Stock: The buffer you keep to handle uncertainty.

- Reorder Point: When to trigger restocking.

- Inventory Turnover Ratio: How often stock sells out and is replaced.

Apple’s lean inventory strategy is famous. They keep minimal stock and rely on fast-moving suppliers to respond to demand. Keeping costs down and margins high.

Getting inventory right is great, but what about scaling your operations? Let’s move to that.

Scaling Your Supply Chain As You Grow

As your business grows, your supply chain needs to scale too.

That means:

- Expanding warehouse locations

- Automating more processes

- Onboarding new logistics partners

- Reviewing your supplier base

Startups like Warby Parker scaled fast by partnering with third-party logistics (3PL) providers, giving them national reach without building warehouses.

Now that growth is covered, let’s zoom out and tie it back to your customer.

The Customer-Centric Supply Chain

A good supply chain doesn’t just move goods, it builds loyalty. Timely deliveries, accurate order fulfillment, and transparent tracking all boost customer satisfaction.

- Optimize last-mile delivery

- Provide real-time updates

- Make returns easy

Chewy, the pet product company, nails this. Their personalized packaging and ultra-fast shipping turn first-time buyers into repeat customers.

FAQs : The Smart Founder’s Guide to Supply Chain Essentials

1. How do I choose my first suppliers?

Start with reliability and communication over cost. Vet them carefully and request trial orders.

2. Is outsourcing fulfillment a good idea for new businesses?

If you’re shipping nationally or globally, yes. 3PLs can save time and costs.

3. How much inventory should I start with?

Base it on forecasted demand and build in safety stock. Monitor and adjust monthly.

4. How important is data in supply chain management?

Critical. Use data to forecast, restock, and spot inefficiencies.

5. What supply chain tech should a startup invest in first?

Start with an inventory management tool and graduate to ERP/WMS as you scale.

Conclusion

The basics of logistics and supply chain management are anything but basic when you see how much impact they have on your business.

Whether you’re still scribbling supplier names in a notebook or already working with 3PLs and WMS software, it pays to strengthen your grip on the fundamentals of supply chain management.

Start simple. Focus on inventory, relationships, and flow. Layer on tech and strategy as you grow. And always keep the customer experience in mind.