Introduction:

In the dynamic landscape of modern warehousing, optimizing the material handling process is crucial for ensuring operational efficiency and overall success. Material handling refers to the movement, storage, and control of goods within a facility, encompassing various tasks and processes. Understanding the importance of material handling and its functions is essential for streamlining operations and maximizing productivity. This article delves into the diverse methods of material handling that can elevate warehouse efficiency, addressing common FAQs to provide a comprehensive guide.

Material Handling Process

Efficient material handling processes stand as the backbone of successful industries and businesses, driving productivity and minimizing operational costs.

In this exploration, we delve into the intricate facets of a well-optimized material handling process, seeking avenues for improvement and increased efficiency.

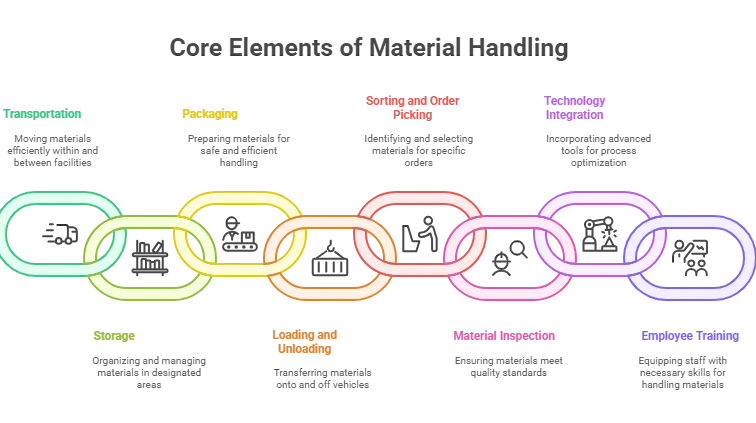

Key Components of Material Handling Process:

Transportation:

- Employing conveyors, forklifts, and Automated Guided Vehicles (AGVs) elevates the fluidity of material movement.

- Strategic layout planning minimizes travel distances, forming the bedrock for an agile transportation system.

- Strategic layout planning, as discussed in warehouse material handling, minimizes travel distances and enhances the fluidity of operations.

Storage:

- Robust storage solutions, including purpose-designed racks and shelves, optimize spatial utilization.

- Introducing an intelligent inventory management system ensures seamless tracking and retrieval of materials.

- Techniques from warehouse space utilization and small warehouse efficiency can help maximize capacity, especially in facilities with limited square footage.

Packaging:

- Precision in packaging processes not only ensures product safety but also mitigates unnecessary waste.

- The integration of automated packaging solutions enhances both speed and accuracy in this critical phase.

- Integrating these systems with a warehouse control system enables real-time inventory tracking and seamless order processing.

Loading and Unloading:

- Thoughtful planning of loading and unloading zones minimizes downtime, fostering continuous workflow.

- Training programs for workers emphasize safe material handling practices, reducing the risk of damage.

- For specialized environments, such as cold storage warehouses, equipment and procedures must be adapted for temperature-sensitive goods.

Sorting and Order Picking:

- Leveraging technology-driven sorting systems accelerates order fulfillment while maintaining accuracy.

- Optimization of order picking routes significantly reduces travel time, enhancing overall efficiency.

- Explore best warehouse picking practices and advanced methods like voice picking technology or implementing zone picking for greater accuracy and speed.

Material Inspection:

- Incorporating quality control checkpoints into the material handling process ensures prompt defect identification and resolution.

- Real-time inspection, facilitated by advanced technologies such as sensors and cameras, elevates quality assurance measures.

- Quality control checkpoints and real-time inspection using sensors and cameras ensure prompt defect identification, supporting a robust warehouse management strategy.

Integration of Technology:

- The infusion of automation and robotics amplifies the speed and precision of material handling operations.

- Implementation of a robust Warehouse Management System (WMS) ensures seamless process integration and heightened operational visibility.

- Adopting latest warehouse technology-including robotics, AI, and IoT-amplifies speed and precision, while smart warehouse technology enables real-time data analytics and intelligent decision-making.

Employee Training:

- Comprehensive training programs empower employees engaged in material handling, instilling a culture of safety and efficiency.

- Ongoing education and skill development initiatives reinforce the importance of each team member in maintaining operational excellence.

Material Handling Process Keyword Insertion:

In warehouse operations, material handling methods are crucial for efficient movement, storage, and control of goods. Warehouses commonly use three main types of material handling: manual, mechanical, and automated methods. Manual handling relies on human labor supported by simple tools like pallet jacks and hand trucks, suitable for lighter loads and smaller warehouses. Mechanical handling employs equipment such as forklifts, conveyor belts, cranes, and hoists to move heavier or bulkier items, enhancing productivity while requiring more investment and maintenance.

Material Handling Process:

- At the core of operational prowess lies an intricately optimized material handling process.

- The journey toward heightened efficiency often commences with a meticulous review of the existing material handling process.

- Unveiling the nuances of an efficient *material handling process* unveils the path to sustained productivity.

- Let’s navigate the landscape of a well-designed *material handling process* to unlock its transformative potential.

- The continuous evaluation and refinement of each facet within the material handling process propel businesses toward a future where agility, precision, and safety converge for unparalleled operational excellence.

Importance Of Material Handling

- Material handling stands as a linchpin in the intricate web of industrial processes, orchestrating the seamless flow of materials from point of origin to destination. Its impact on operational efficiency, cost dynamics, and workplace safety is nothing short of pivotal.

Enhanced Efficiency:

- At the core of material handling lies the ability to bolster operational efficiency. By streamlining the movement of raw materials and finished products, businesses can eradicate bottlenecks, ensuring a more fluid production cycle.

- The meticulous orchestration of material flow translates directly into reduced downtime, enabling companies to meet production deadlines with heightened precision.

- The warehouse productivity blog offers actionable strategies for improving operational efficiency, while warehouse methodology provides a holistic approach to managing inventory, labor, and order fulfillment.

Cost Savings:

- The judicious application of material handling methodologies translates into substantial cost savings. By curbing manual labor requirements and minimizing the risk of goods damage, businesses can navigate the financial landscape with increased prudence.

- Investing in avant-garde material handling equipment and technologies serves as a proactive measure, paving the way for sustained cost-effectiveness through resource optimization.

Workplace Safety:

- Material handling practices serve as a bulwark for workplace safety. By mitigating the need for manual handling of heavy loads and minimizing the probability of accidents, industries create an environment where employee safety takes precedence.

- The implementation of ergonomic material handling solutions contributes to a safer working milieu, reducing the incidence of workplace injuries and the associated financial and human costs.

Inventory Management:

- A well-orchestrated material handling system is instrumental in precise inventory management. It provides the tools for accurate tracking, preventing the pitfalls of overstocking or stockouts.

- Real-time visibility into inventory levels empowers businesses to make informed decisions, ensuring that the right materials are on hand when needed—a crucial aspect of optimizing supply chain dynamics.

Importance of Material Handling:

- In essence, the fabric of modern industry is woven with the threads of material handling. Its influence resonates across operational domains, encapsulating efficiency enhancement, cost-savings wizardry, the fortress of workplace safety, and the alchemy of inventory precision.

- Recognizing and prioritizing the pivotal role of material handling is not just a strategic imperative; it is the cornerstone of resilience and competitiveness in the dynamic landscape of contemporary business. As industries evolve, so must their embrace of advanced material handling technologies and methodologies to not just survive but thrive.

Functions Of Material Handling

Material handling serves as the backbone of efficient and seamless industrial operations, orchestrating the intricate dance of goods within a facility. Beyond the mere physical movement of items, material handling embraces a multitude of critical functions. Here, we delve into the nuanced roles material handling plays, offering a fresh perspective through a comprehensive set of pointers:

Facilitates Efficient Movement:

- At its core, material handling is about orchestrating the dynamic and efficient transportation of goods within a facility.

- This involves deploying an arsenal of tools and technologies, ranging from conveyors to forklifts, to minimize delays and optimize the overall operational flow.

Optimizes Storage Space:

- Material handling systems are meticulously designed to maximize storage space, employing innovative solutions such as racks and automated storage systems.

- The objective extends beyond mere space conservation to creating an organizational structure that facilitates easy retrieval when needed.

Enhances Productivity:

- A pivotal function of material handling is to elevate productivity by ensuring a seamless flow of materials.

- Well-choreographed material handling processes contribute to reduced downtime, expedited order fulfillment, and an overarching enhancement in productivity metrics.

Ensures Safety:

- Safety is paramount in any work setting, and material handling is intrinsic to fostering a secure workplace.

- Adherence to stringent safety protocols and the integration of ergonomic designs in material handling systems minimize the risk of accidents, placing a premium on the well-being of the workforce.

Supports Order Picking and Assembly:

- Material handling systems are bespoke to support the intricate processes of order picking and assembly lines.

- This involves the timely and precise transport of materials to assigned assembly stations, ensuring a harmonious and efficient production process.

Reduces Costs:

- Material handling strategies are intricately woven into cost management initiatives, aiming to minimize waste, protect goods from damage, and optimize the utilization of labor resources.

- The streamlined processes not only reduce operational costs but also contribute to an augmented bottom line.

Facilitates Quality Control:

- Material handling takes center stage in implementing rigorous quality control measures.

- Through meticulous handling and storage practices, material handling systems safeguard the integrity of goods, ensuring the final products meet stringent quality standards.

Adapts to Changing Demand:

- Successful material handling systems are designed with adaptability at their core, capable of seamlessly accommodating changes in production volume and variations in product types.

- This flexibility ensures that the material handling process remains agile, responding effectively to dynamic market demands.

Promotes Sustainability:

- Modern material handling places a premium on sustainability by incorporating energy-efficient systems and environmentally friendly practices.

- Aligned with corporate sustainability goals, material handling contributes to the broader initiative of reducing the environmental footprint.

Enhances Communication:

- Effective communication is the lifeblood of material handling, ensuring seamless coordination between different stages of production.

- Clear communication pathways prevent bottlenecks and discrepancies, fostering a harmonious and efficient material handling process.

Material handling emerges as a linchpin in the intricate machinery of industrial endeavors. Its multifaceted roles, from ensuring safety to championing sustainability, underscore its pivotal contribution to the success and efficiency of businesses.

What Is Material Handling

Material handling stands as a cornerstone in the seamless functioning of industries, orchestrating the intricate dance of goods from origin to destination. This holistic process involves the strategic management of movement, storage, control, and safeguarding of materials and products throughout their life cycle. Let’s embark on an exploration of the intricacies that define the world of material handling:

Importance of Material Handling:

- At the heart of industrial processes, material handling enhances efficiency and minimizes operational downtime.

- By optimizing workflow and reducing manual labor, material handling becomes a catalyst for heightened productivity.

- A finely tuned material handling system acts as a financial steward, conducting cost-saving measures that resonate with improved profitability.

Core Components of Material Handling:

- Conveyors, acting as mechanical virtuosos, transport materials seamlessly within facilities, connecting disparate points in the production continuum.

- Storage equipment, silent sentinels of organization like racks and bins, lay the groundwork for meticulous material storage.

- Material handling equipment, embodied by forklifts and cranes, executes the choreography of material movement within the expansive stage of an industrial facility.

Safety Considerations in Material Handling:

- Safety takes center stage, ensuring a harmonious performance by preventing accidents and injuries during material handling routines.

- Rigorous training and adherence to safety protocols form the backbone of a responsible material handling ensemble.

- Ergonomic design principles guide the graceful movements of material handling equipment, fostering a safer work environment.

Automation in Material Handling:

- Automation, an avant-garde conductor, transforms material handling operations with the seamless integration of robotics and conveyor systems.

- This technological virtuosity enhances efficiency, reduces the risk of human error, and orchestrates non-stop performances through 24/7 operation.

- Sensors and artificial intelligence join the ballet, refining precision and responsiveness in the intricate dance of material handling systems.

Sustainable Material Handling Practices:

- Material handling takes a bow for sustainability, as eco-friendly practices make their mark on the center stage of environmental consciousness.

- Recycling and reusing packaging materials take the lead, reducing waste and enlivening the spirit of a greener approach.

- Energy-efficient maneuvers of material handling equipment contribute to the grand spectacle of resource conservation.

Technological Advancements in Material Handling:

- RFID technology and real-time tracking systems pirouette through the narrative, enhancing visibility and control over materials in transit.

- Predictive maintenance, orchestrated by IoT sensors, takes a bow, reducing downtime and elevating the reliability of material handling equipment.

- Cloud-based software solutions dance gracefully, enabling seamless monitoring and management of material handling performances.

Customization in Material Handling Solutions:

- Tailoring material handling solutions to the unique rhythm of each industry ensures a performance that resonates with optimal adaptability.

- Modular systems, the versatile dancers, facilitate seamless customization and scalability, adapting to the evolving cadence of business requirements.

- The integration of smart technologies, the avant-garde artists, allows real-time adjustments, infusing a dynamic element into the choreography of material handling processes.

Material handling emerges not just as a logistical necessity but as a grand symphony where each component plays a crucial role in the orchestration of operational excellence. With a commitment to innovation, sustainability, and safety, the world of material handling continues to captivate audiences across diverse industries, ensuring a performance that echoes with efficiency, precision, and adaptability.

FAQs:

1.What is material handling, and why is it important?

Material handling involves the movement and management of goods within a warehouse. Its significance lies in enhancing efficiency, reducing costs, and improving overall workflow.

2.What are the key functions of material handling?

Material handling functions include transportation, storage, picking, and packaging, all integral for seamless operations in a warehouse.

3.How does material handling contribute to operational efficiency?

Material handling streamlines processes, minimizes errors, and optimizes resource utilization, thereby increasing overall operational efficiency.

4.What methods are employed in the material handling process?

Various methods, such as conveyors, robotics, and automated systems, are used to handle materials efficiently, catering to diverse warehouse needs.

5.How does effective material handling impact supply chain management?

Efficient material handling positively influences supply chain management by ensuring timely deliveries, reducing lead times, and minimizing disruptions.

6.Are there specific challenges associated with material handling in warehouses?

Common challenges include inventory inaccuracies, bottlenecks in processes, and the need for skilled labor to operate advanced handling equipment.

7.What role does technology play in modern material handling practices?

Technology, including RFID, IoT, and AI, is instrumental in automating material handling processes, enhancing accuracy, and improving overall efficiency.

8.What are the main types of material handling equipment used in warehouses?

Material handling equipment can be broadly categorized into four types: storage and handling equipment (like racks and shelves), engineered systems (such as conveyors and automated storage/retrieval systems), industrial trucks (including forklifts and pallet jacks), and bulk material handling equipment (like hoppers and silos). Each type serves a specific function, from storing goods efficiently to moving large quantities of materials quickly. The choice of equipment depends on warehouse size, product type, and operational requirements.

9.How does automation enhance the material handling process?

Automation introduces technologies such as robotics, conveyor belts, and automated guided vehicles (AGVs) to perform repetitive or complex tasks with greater speed and accuracy. This reduces the reliance on manual labor, minimizes errors, and enables 24/7 operations. As a result, warehouses can handle higher volumes, improve safety, and achieve greater consistency in their processes.

Conclusion:

In conclusion, implementing efficient methods of material handling is pivotal for achieving high productivity in warehouse operations. From conveyors to advanced automation, the diverse approaches discussed contribute to smoother workflows and improved outcomes. For cutting-edge solutions in material handling, consider Qodenext, a brand synonymous with innovation and reliability in the logistics industry. Elevate your warehouse capabilities with Qodenext’s advanced technologies.