Efficient warehouse management is crucial for businesses dealing with inventory. Whether it’s a large-scale distribution center or a small storage facility, keeping track of stock ensures smooth operations, prevents losses, and improves customer satisfaction. One of the most effective tools to achieve this is a warehouse inventory checklist.

A warehouse inventory checklist serves as a systematic approach to tracking stock levels, monitoring item conditions, and maintaining order in storage areas. But why is it essential, and how can it transform warehouse operations? Let’s explore its significance and how it benefits your business.

What is a Warehouse Inventory Checklist?

A warehouse stock checklist is a structured document or digital tool used to track inventory status, movement, and condition. It contains details such as:

- Item descriptions

- Stock levels

- Storage locations

- Expiry or damage reports

- Restocking schedules

- Supplier details

Warehouse managers and employees use this checklist to ensure proper stock management, minimise errors, and streamline logistics.

Why is a Warehouse Inventory Checklist Essential?

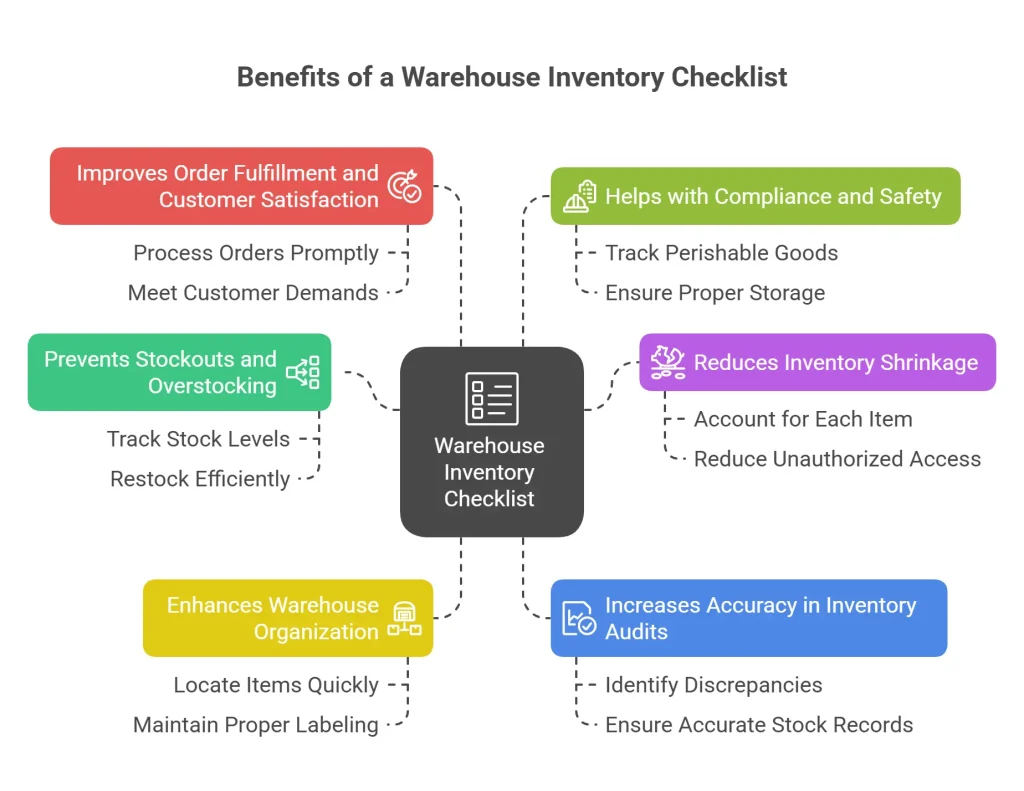

1. Prevents Stockouts and Overstocking

One of the primary challenges in warehouse management is maintaining the right balance between demand and supply. Overstocking leads to higher holding costs, while stockouts can result in lost sales and dissatisfied customers. A warehouse stock checklist helps businesses track stock levels and restock efficiently, ensuring that inventory aligns with demand.

2. Reduces Inventory Shrinkage

Inventory shrinkage leads to significant financial losses. Various problems like theft, misplacement, and manual errors create backlogs. A warehouse inventory checklist ensures that each item is accounted for, reducing the chances of unauthorized access, misplaced goods, or unnoticed damages.

3. Enhances Warehouse Organization

A well-organised warehouse improves efficiency and reduces order fulfillment time. By using a warehouse inventory checklist, employees can quickly locate items, restock shelves systematically, and maintain proper labeling. This leads to faster retrieval of products and improved workflow.

4. Increases Accuracy in Inventory Audits

Regular inventory audits help identify discrepancies and ensure accurate stock records. A warehouse inventory management checklist simplifies the audit process by providing a clear, up-to-date record of stock levels. This reduces human errors and ensures compliance with industry regulations.

5. Improves Order Fulfillment and Customer Satisfaction

Delayed shipments due to inventory mismanagement can harm a company’s reputation. A warehouse inventory checklist ensures that orders are processed promptly and accurately. By keeping track of stock availability, businesses can meet customer demands efficiently, leading to better satisfaction and repeat purchases.

6. Helps with Compliance and Safety

Many industries require warehouses to follow strict compliance and safety regulations. A warehouse inventory checklist includes tracking of perishable or hazardous goods, ensuring that all items are stored under the right conditions and disposed of properly if expired.

Components of an Effective Warehouse Inventory Checklist

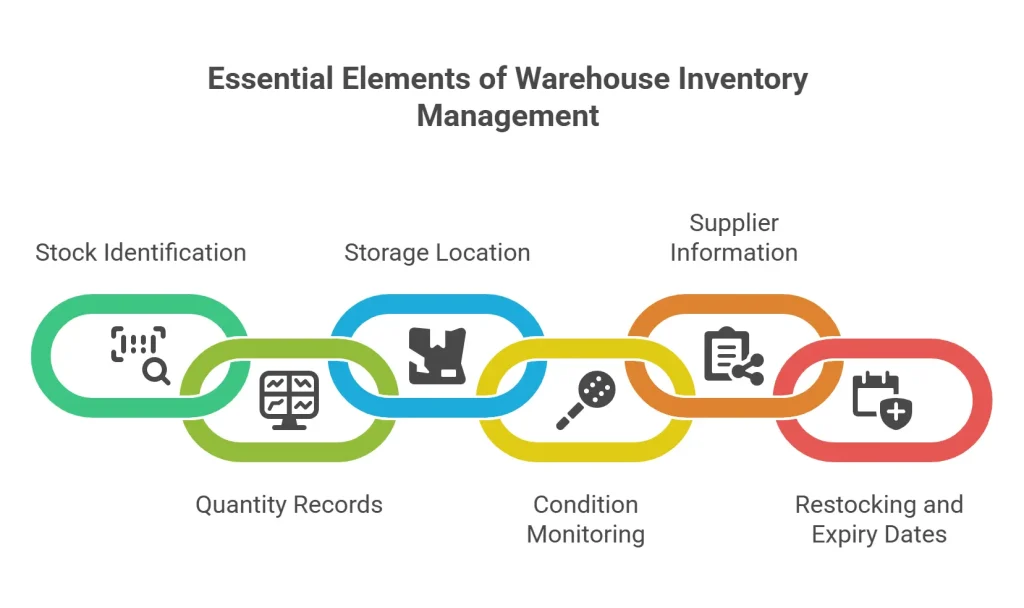

To maximise efficiency, a warehouse inventory checklist should include the following elements:

1. Stock Identification

Each item should have a unique identification code (SKU or barcode) for easy tracking.

2. Quantity Records

The checklist should include real-time stock levels to ensure accurate restocking.

3. Storage Location

Clearly defined storage locations prevent misplacement and facilitate quick retrieval.

4. Condition Monitoring

Regular inspections should be included in the checklist to identify damaged, expired, or defective goods.

5. Supplier Information

Tracking supplier details helps in maintaining strong vendor relationships and improving restocking efficiency.

6. Restocking and Expiry Dates

The checklist should indicate restocking schedules and expiry dates to minimize waste and prevent shortages.

How to Create and Implement a Warehouse Inventory Checklist?

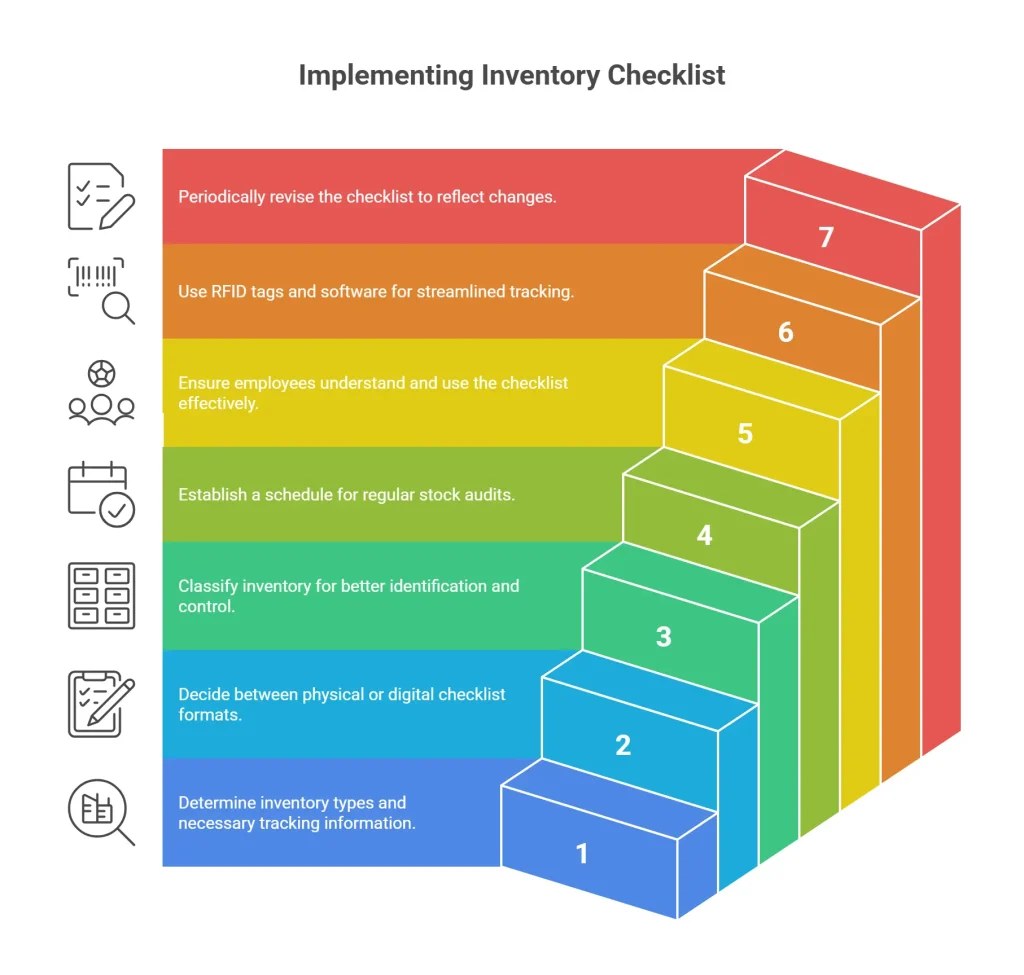

Creating a warehouse inventory checklist involves a step-by-step approach to ensure all aspects of inventory are covered.

Step 1: Assess Inventory Needs

Determine what type of inventory you manage and what information is necessary for efficient tracking.

Step 2: Choose the Right Format

A warehouse inventory checklist can be in physical format (printed sheets) or digital format (inventory management software or spreadsheets). Digital checklists are more efficient as they allow real-time updates.

Step 3: Categorise Inventory

Classify inventory based on type, demand, perishability, or storage location. This helps in faster identification and better stock control.

Step 4: Set Up a Routine Check Process

Establish a schedule for checking stock levels, conditions, and storage arrangements. Weekly or monthly audits should be a part of the warehouse routine.

Step 5: Train Warehouse Staff

Ensure that employees understand the checklist’s purpose and how to use it effectively. Proper training minimises errors and ensures compliance.

Step 6: Integrate Technology

Modern warehouses use RFID tags, barcode scanners, and inventory management software to streamline tracking. Digitalising the warehouse inventory checklist enhances accuracy and efficiency.

Step 7: Regularly Update the Checklist

Inventory needs change over time. Businesses should update their warehouse inventory checklist periodically to reflect new stock, discontinued products, and changes in demand.

The Role of Technology in Warehouse Inventory Management

Traditional inventory checklists have been replaced by digital solutions that automate tracking and reporting. Businesses are increasingly using:

- Warehouse Management Systems (WMS) – Software that integrates inventory tracking with warehouse operations.

- RFID and Barcode Scanners – Reduce manual errors and improve stock accuracy.

- Cloud-Based Inventory Systems – Allow remote access to real-time inventory data.

- Using these technologies alongside a warehouse inventory checklist enhances efficiency, reduces errors, and improves decision-making.

Common Mistakes to Avoid in Warehouse Inventory Checklists

While a warehouse inventory audit checklist is a powerful tool, common mistakes can reduce its effectiveness. Here are some pitfalls to watch out for:

- Inconsistent Record-Keeping – Inaccurate data can lead to stock discrepancies. Ensure regular updates.

- Not Conducting Routine Audits – Skipping periodic checks can result in unnoticed losses or mismanagement.

- Overcomplicating the Checklist – Keep it simple and relevant to avoid confusion.

- Ignoring Technology – Manual tracking increases the risk of errors. Digital solutions are more reliable.

- Lack of Staff Training – Employees should be well-trained in using the checklist effectively.

Conclusion

A warehouse inventory checklist is a fundamental tool for any business managing stock. It helps prevent stockouts, reduce losses, enhance warehouse organisation, and improve customer satisfaction. Whether using a manual checklist or an advanced digital solution, maintaining an accurate inventory record is crucial for efficient warehouse operations.

By implementing a well-structured warehouse inventory checklist, businesses can optimise their supply chain, reduce costs, and stay ahead of competitors in today’s fast-paced market.

Are you ready to enhance your warehouse efficiency? Contact Qodenext today.

FAQs – Warehouse Inventory Checklist

1. How often should a warehouse checklist be updated?

A warehouse checklist should be updated in real-time or at least once per week. High-turnover industries may require daily updates, while others may review stock monthly.

2. Can a warehouse checklist help reduce costs?

Yes, by preventing overstocking, stockouts, and inventory shrinkage, a warehouse stock checklist helps businesses reduce storage costs and avoid financial losses.

3. What’s the difference between a digital and a physical inventory count checklist?

A manual warehouse stock checklist is paper-based, requiring employees to write down stock details. A digital checklist uses inventory management software, allowing automated tracking, real-time updates, and fewer human errors.

4. How does a warehouse stock checklist improve order accuracy?

It ensures that stock records are up to date, preventing order processing errors, reducing incorrect shipments, and improving customer satisfaction.

5. What are the key features of an effective warehouse stock checklist?

An effective warehouse stock checklist includes product details, stock levels, storage locations, condition monitoring, supplier information, and restocking schedules.

6. Can small businesses benefit from a warehouse stock checklist?

Absolutely! Even small businesses with limited stock can use a warehouse checklist to prevent mismanagement, optimize inventory, and improve efficiency.

7. What is the best software for managing a warehouse stock checklist?

Popular inventory management software includes SAP WMS, NetSuite, Fishbowl, and Zoho Inventory. These systems help automate stock tracking and reporting.