Hologram stickers serve as a critical tool for authentication, branding, and tamper-evident packaging. Whether you’re a business looking to secure your products or a collector protecting your merchandise, applying these labels correctly is just as important as choosing high-quality holograms.

Improper application can cause peeling, air bubbles, or even render the sticker ineffective. This guide breaks down everything you need to know for a smooth and easy hologram sticker application, step by step.

Why Hologram Stickers Matter

Before we delve into application techniques, it’s important to understand what makes hologram stickers so valuable. These tamper-evident labels are typically made from polyester or vinyl materials and embedded with a laser-generated 3D image that changes colour or appearance when viewed from different angles.

Hologram stickers are commonly used for:

- Brand Protection: Prevent counterfeiting of products.

- Security Authentication: Ensure original packaging and goods are intact.

- Tracking and Inventory: Serve as part of the traceability systems.

- Visual Appeal: Enhance the packaging with a premium touch.

Given their multifaceted utility, proper application becomes essential. A misaligned or damaged hologram can reduce both its aesthetic and security value.

Pre-Application Preparation

1. Clean the Surface

One of the most common reasons for sticker failure is applying to a dusty, oily, or moist surface. Use an isopropyl alcohol wipe or a lint-free cloth dipped in a mild detergent solution to clean the area. Avoid harsh chemicals that might leave a residue.

Tip: The surface must be dry, smooth, and at room temperature before application.

2. Choose the Right Material for the Right Surface

Not all hologram stickers are created equal. There are different adhesive types suited for various surfaces—plastic, metal, glass, cardboard, and even textiles. Ensure that your sticker’s adhesive is compatible with the target surface.

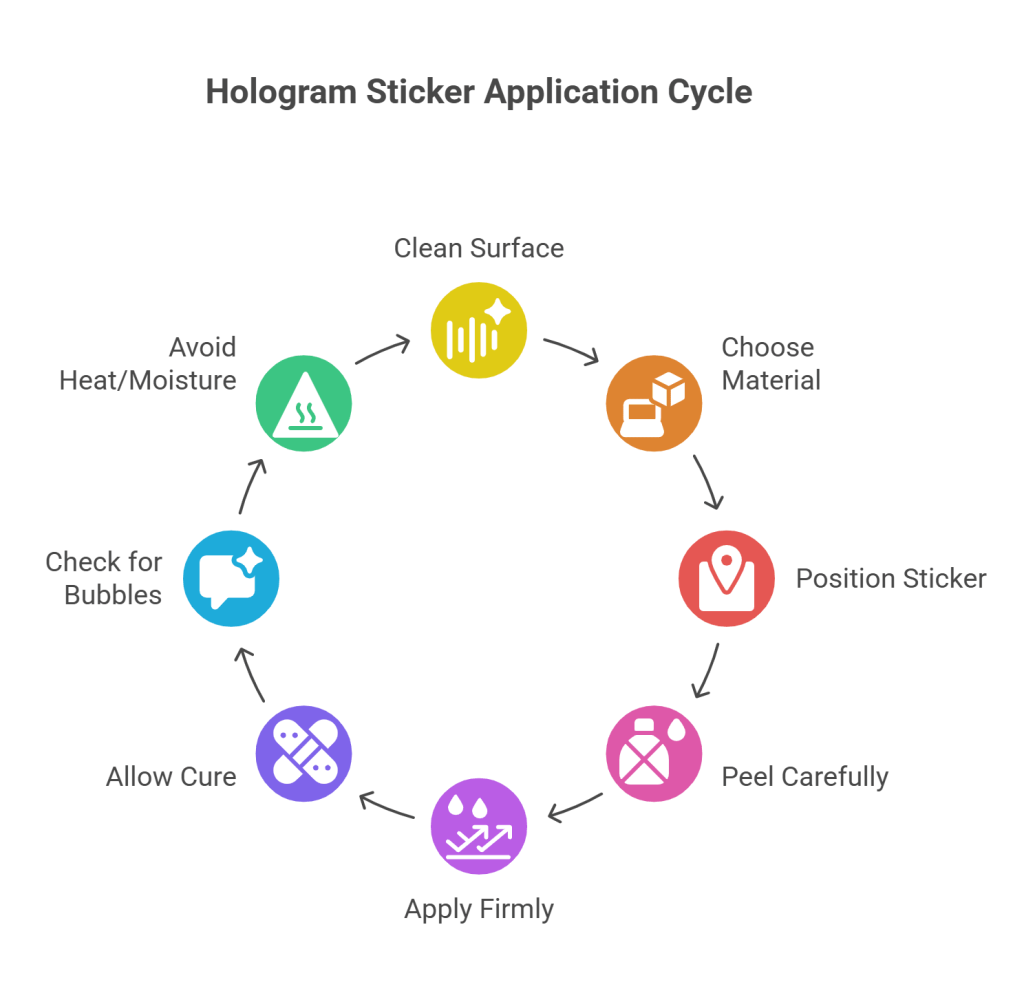

Step-by-Step Guide for Application

Step 1: Positioning is Key

Before peeling off the backing, do a dry run. Hold the holographic label above the surface and determine the precise position. You can use a small piece of painter’s tape as a reference mark if necessary.

Pro Tip: If you’re applying multiple stickers, use a ruler or stencil to maintain consistent alignment across all items.

Step 2: Peel Carefully

Using clean hands or tweezers, peel the sticker slowly from its backing. Avoid touching the adhesive side to prevent oil transfer, which may weaken the bond.

Step 3: Apply Gently but Firmly

Place one edge of the sticker on the surface first and slowly press down while smoothing out the rest of the sticker with a plastic squeegee, credit card, or silicone roller. This technique minimises air bubbles and creases.

Post-Application Tips

1. Allow the Adhesive to Cure

Even pressure-sensitive adhesives require a few hours to bond fully. Avoid touching or manipulating the sticker immediately after application.

2. Check for Air Bubbles

If air bubbles appear, use a pin to puncture them gently and push out the air with a squeegee. Some authentic hologram stickers come with air-release channels built into the adhesive layer to prevent this issue.

3. Avoid Moisture and Heat for 24 Hours

To ensure maximum bond strength, keep the product away from excessive heat or moisture for at least a day.

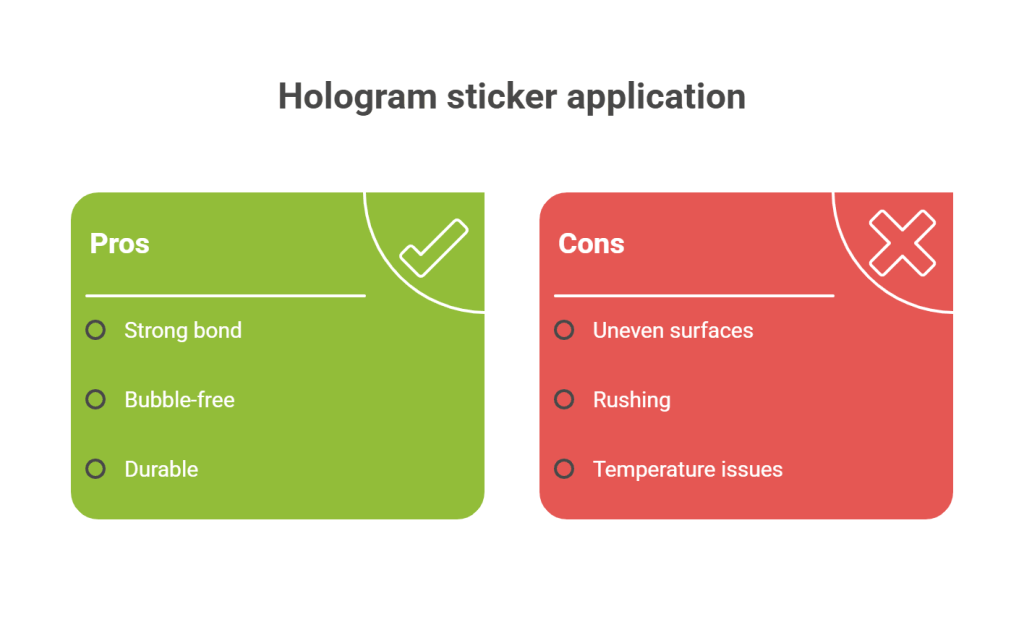

Common Mistakes and How to Avoid Them

1. Applying on Uneven or Textured Surfaces

This can cause the sticker to warp or peel. If necessary, sand down or flatten the area beforehand. This will help you enable robust anti-counterfeiting operations.

2. Rushing the Process

Slapping a sticker on without alignment or smoothing can create permanent creases or misplacement. Take your time.

3. Ignoring Temperature and Humidity

Ideal application temperatures for hologram stickers range from 15°C to 30°C (59°F to 86°F). High humidity can compromise adhesion.

Special Considerations for Industrial Applications

For businesses applying security hologram stickers in bulk:

- Use Label Dispensers: Manual or automated dispensers can help maintain consistency.

- Conduct Sample Testing: Always test a few stickers on the packaging material before full-scale application.

- Batch Coding: Some holograms can be printed with batch numbers or serial codes for tracking.

If your company integrates these labels into a high-speed production line, consult with the sticker provider to ensure the adhesive properties and backing liner suit your machinery.

Long-Term Care of Custom-Security Hologram Stickers

Once applied, maintenance is minimal but still essential:

- Do not scrub or scrape the sticker—this can remove the holographic film.

- Avoid exposure to direct sunlight for extended periods, as UV rays can degrade certain adhesives and colour layers.

- Clean with a soft, dry cloth if necessary.

Environmental and Regulatory Compliance

Certain industries, such as pharmaceuticals and electronics, require hologram stickers to comply with regulatory standards. Always request documentation or certification from your supplier.

- RoHS Compliant

- FDA or ISO-Certified Materials

- Tamper-Evident Standards (e.g., VOID pattern)

These ensure that your sticker solution is not only functional but also legally viable.

FAQs on Hologram Sticker Application

1. Can I reuse a hologram sticker once removed?

No. These stickers are designed for single use. Most will show tamper-evident patterns or break apart upon removal.

2. What is the best surface for applying custom hologram stickers?

Smooth, clean surfaces like plastic, glass, or metal work best. Textured or dirty surfaces reduce adhesive strength.

3. How can I remove air bubbles after application?

Use a sterilised pin to puncture the bubble gently and push the air out with a squeegee or card.

4. How to print hologram stickers?

Printing stickers requires vinyl, printers, a cutting machine and scissors. The design is pasted onto the holographic material and then cut to give a uniform shape.

5. How long do holographic stickers last once applied?

Most high-quality holographic stickers can last 3–5 years, depending on environmental exposure and usage conditions.

6. Can I laminate over a hologram sticker?

It’s generally not recommended unless the sticker is specifically made for lamination. Lamination can reduce the visibility of the holographic effect.

Conclusion

Whether you are applying one label or a thousand, the key to smooth and easy hologram sticker application lies in preparation, precision, and patience. Proper surface cleaning, alignment, and pressure application are non-negotiables in achieving a seamless result.

As businesses and consumers alike rely more on visible markers of authenticity, hologram stickers continue to be a powerful blend of security and style. Take the time to apply them correctly—you’ll be safeguarding both your product and your reputation. Need robust traceability to prevent counterfeiting? Contact Qodenext for seamless traceability solutions.