In a typical factory, there are two powerhouse systems at work – MES (Manufacturing Execution System) and ERP (Enterprise Resource Planning).

One runs the shop floor, and the other handles business operations.

But when these two systems operate in silos, inefficiencies creep in, data gets duplicated, and decision-making slows down.

That’s why ERP integration with MES is not just nice to have – it’s now a necessity.

This blog unpacks why MES ERP integration is the key to smart manufacturing. From real-time data exchange to full traceability, we’ll break down how connected systems are reshaping factories in 2025 and beyond.

What Happens Without Integration?

Imagine running your production line without knowing your inventory status or planning your shop floor without sales forecasts.

When MES integration with ERP is missing, operations rely on manual updates or delayed batch data, leading to misaligned schedules, wasted resources, and costly downtime.

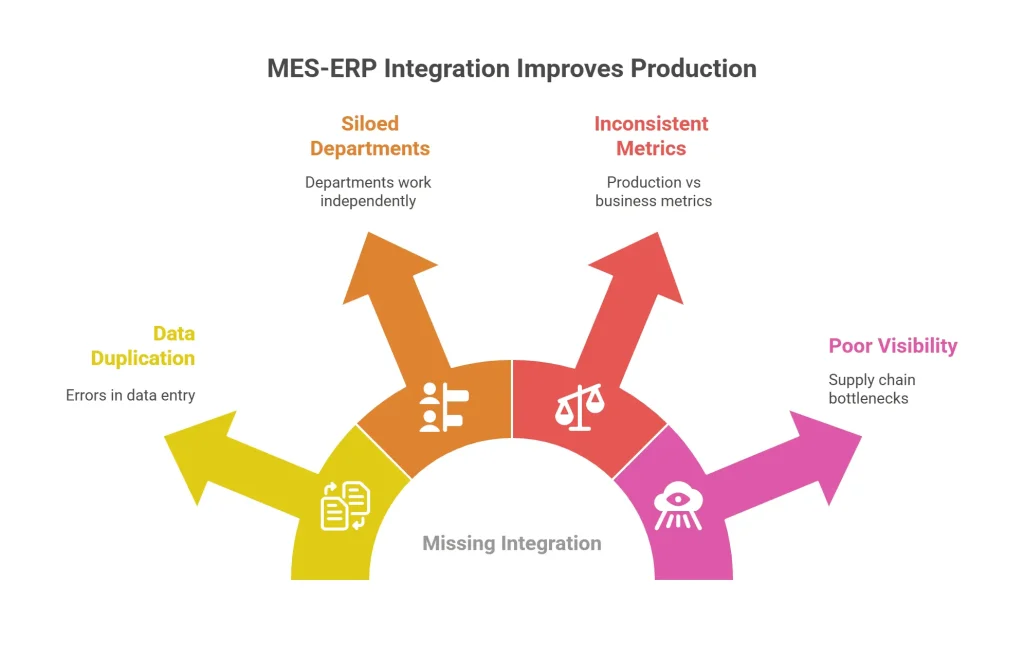

Lack of integration often leads to:

- Duplicate data entry and errors

- Siloed departments

- Inconsistent production vs. business metrics

- Poor visibility into supply chain bottlenecks

Now that we’ve seen the risks of disconnected systems, let’s dive into why connecting ERP and MES matters so much.

Real-Time Visibility Across Operations

When ERP and MES integration is done right, real-time data flows seamlessly between the shop floor and the front office. If a production batch is delayed, planners see it immediately. If sales spike, MES adjusts production priorities.

Take Siemens for example. Their MES platform integrates with SAP ERP to create closed-loop manufacturing systems that sync sales forecasts, machine performance, and material usage in real-time.

This level of visibility helps:

- Improve responsiveness to market changes

- Reduce production downtime

- Align production plans with business goals

Now that we understand the value of data flow, let’s look at another big win: traceability.

Complete End-to-End Traceability

In industries like pharmaceuticals, automotive, and food, traceability isn’t optional – it’s compliance.

MES ERP integration ensures every material, part, and process is recorded and can be traced from raw material to finished product. This is crucial for recalls, audits, and compliance with industry standards.

Companies like Nestlé use MES systems connected to ERP to trace every ingredient back to its source and match it to batch records, supplier lots, and final product labeling. ERP integration with MES makes traceability automatic, rather than an afterthought.

Now that traceability is sorted, let’s move on to the financial side of things.

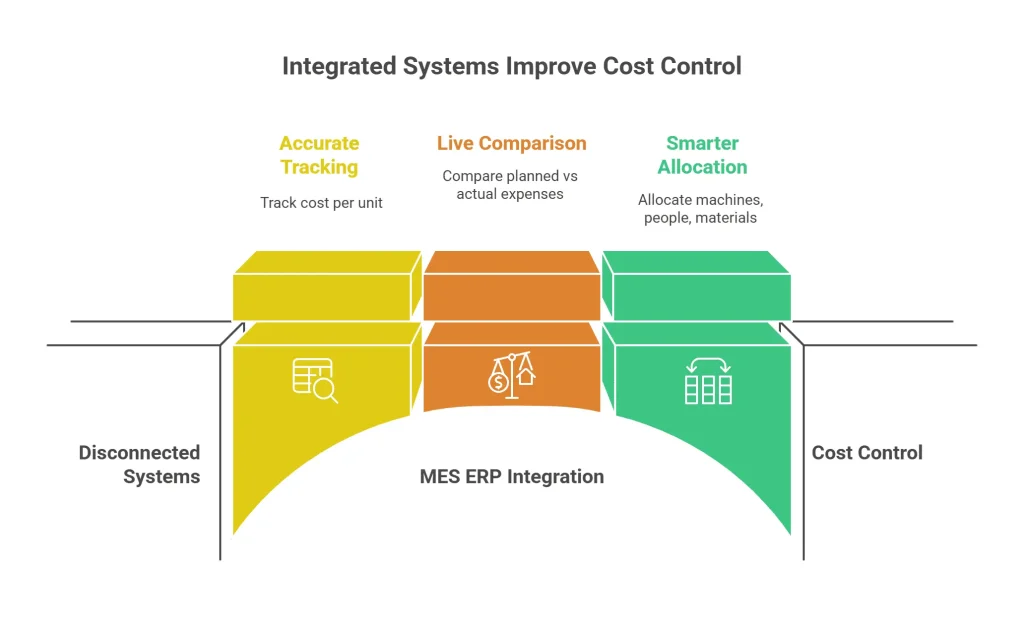

Better Cost Control and Resource Allocation

Disconnected systems create blind spots when it comes to true manufacturing costs. MES knows how many units were produced; ERP knows the cost of labor and materials. Put them together and you unlock powerful cost insights.

MES ERP integration enables:

- Accurate cost-per-unit tracking

- Live comparison of planned vs. actual expenses

- Smarter allocation of machines, people, and raw materials

For instance, Toyota’s just-in-time manufacturing system relies heavily on integrated ERP-MES platforms to balance resource use with lean production.

Let’s now look at how this integration can improve demand planning.

Smoother Demand Forecasting and Production Scheduling

MES integration with ERP brings sales, inventory, and production into one synchronized loop. Demand spikes don’t take manufacturers by surprise because MES is already adjusting batch sizes or shift schedules in response to ERP-driven forecasts.

Companies like Procter & Gamble leverage MES and ERP integration to dynamically adjust production runs based on real-time retail data, minimizing waste and ensuring on-time delivery.

Once forecasts are aligned with factory output, the next step is ensuring compliance.

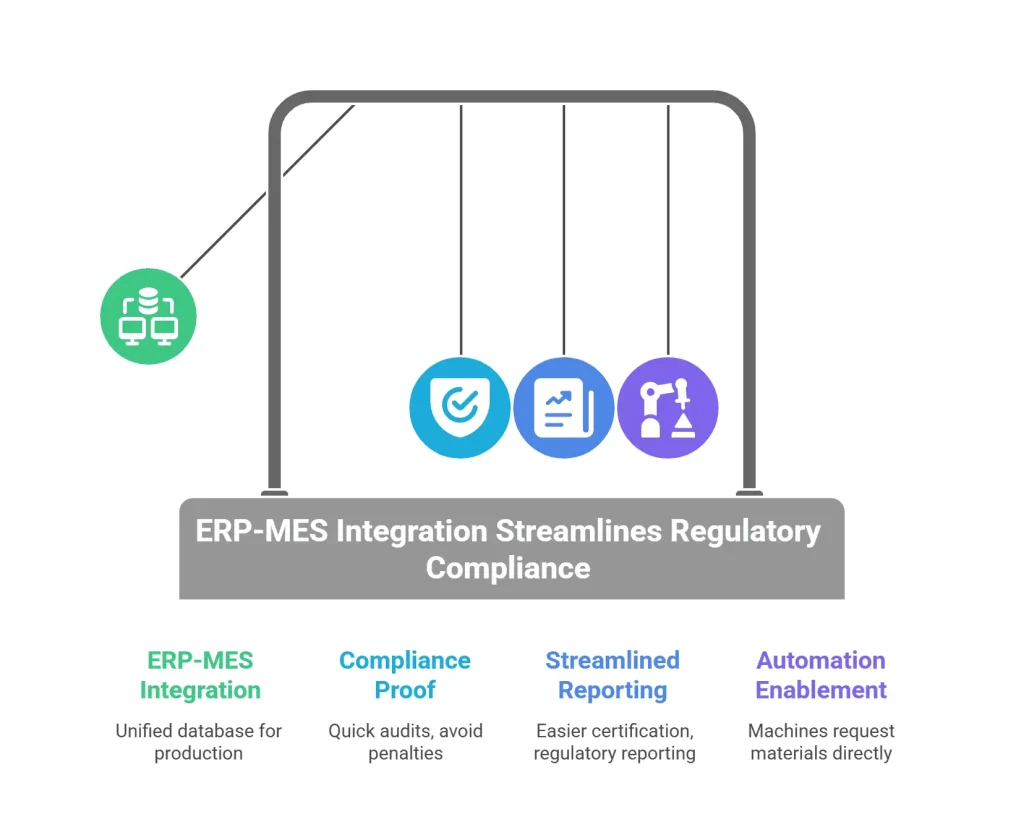

Regulatory Compliance Made Easier

Whether it’s FDA regulations, ISO standards, or industry-specific audits, documentation is key.

With ERP and MES integration, all production data, process controls, quality checks, and shipment records are captured in one unified database automatically.

This helps businesses:

- Prove compliance quickly during audits

- Avoid costly penalties

- Streamline certification and regulatory reporting

Johnson & Johnson uses ERP-MES integration across its global manufacturing facilities to ensure quality standards are enforced consistently.

Let’s now explore the role of automation and how integration supercharges it.

Enabling Automation and Smart Factory Initiatives

A key building block of Industry 4.0 is seamless communication between systems.

MES ERP integration allows:

- Machines to request materials directly from ERP

- MES to pause or escalate workflows based on ERP exceptions

- Predictive maintenance data to inform supply chain planning

Bosch is a notable example of a smart factory leader using ERP-MES integration to enable autonomous manufacturing cells that self-adjust based on real-time conditions.

Next, let’s consider what you should look for when implementing integration.

Important Considerations Before You Integrate

Not all integrations are created equal. Before jumping in, companies should ask:

- Does the MES support standard protocols (e.g., ISA-95, OPC-UA)?

- Can the ERP system handle real-time data exchange?

- Do we need middleware for data harmonization?

- Is cloud-based or on-prem integration more suitable?

A well-executed MES integration with ERP strategy balances short-term wins with long-term scalability.

FAQs: Why MES Without ERP Is Holding Your Factory Back

1. Can small manufacturers afford MES-ERP integration?

Yes. Scalable solutions like cloud MES platforms and plug-and-play APIs make integration accessible even for SMEs.

2. What industries benefit most from this integration?

Pharma, food and beverage, automotive, and electronics gain the most due to high compliance and traceability needs.

3. How long does ERP-MES integration take?

Anywhere from 3 to 12 months depending on system complexity, customization, and internal readiness.

4. What challenges should be expected?

Data silos, legacy system compatibility, lack of IT expertise, and change management are common roadblocks.

5. Is cloud better than on-prem integration?

Cloud-based solutions offer faster deployment and lower costs, while on-prem is preferred for high-security environments.

Conclusion

If you’re looking to improve factory efficiency, reduce costs, and strengthen compliance, ERP integration with MES isn’t just an upgrade – it’s essential.

From real-time visibility to full traceability, the benefits of MES ERP integration go far beyond IT. They touch every part of your manufacturing strategy.

As more companies aim to build smart factories and lean operations, now is the time to embrace ERP and MES integration and future-proof your production floor.