Remember the days when inventory audits meant teams of people climbing ladders, scanning barcodes manually, and spending hours – if not days – trying to reconcile stock levels? It was tedious, error-prone, and often exhausting. But that’s quickly changing.

Today, drones are quietly – and quite literally – flying into warehouses, transforming how businesses manage and audit their inventory.

Drone inventory management is no longer a futuristic fantasy. It’s here, and it’s solving some of the biggest problems that warehouses face: inefficiency, inaccuracy, and unsafe working conditions. Think of it this way – while traditional inventory audits crawl, drone-based audits fly.

This blog dives deep into how warehouse drones are rewriting the rules of inventory management, from their core functionality to real-world impact.

Understanding Drone Inventory Management

So, what exactly is drone inventory management?

At its core, it’s about using autonomous flying drones equipped with barcode scanners, RFID readers, and cameras to perform inventory checks. These drones can zip through warehouse aisles, scan racks several feet above the ground, and instantly sync that data with your warehouse management system (WMS).

Imagine drones conducting inventory counts overnight while the warehouse is empty – no need for ladders, scissor lifts, or shut-downs. That’s the kind of operational agility that drones are bringing to the table.

Companies like IKEA and Walmart are already piloting and scaling warehouse drone programs, proving the technology isn’t just viable – it’s valuable. Now that we’ve seen the benefits, let’s dive into how these drones actually function in a real-world warehouse setting.

How Warehouse Drones Actually Work

A warehouse drone is more than just a flying camera. It’s an intelligent auditing tool. Here’s a breakdown of how it functions:

- Smart Navigation: Drones navigate using GPS, obstacle-detection sensors, and sometimes LiDAR, which helps them fly safely through tight warehouse aisles without crashing into racking or infrastructure.

- Scanning on the Fly: High-definition cameras and barcode or RFID scanners allow drones to scan pallet labels and product barcodes in real-time. Some systems also use AI to recognize labels even when they’re partially obscured or damaged.

- Instant Sync with WMS: Once scanned, the data is transmitted to the WMS, updating stock records instantly. No delay. No data loss.

- Autonomous Flight Paths: Most drones can be pre-programmed with specific flight paths. They know exactly where to go and what to scan, without human input.

This seamless blend of hardware and software is what makes drone warehouse inventory both efficient and scalable. Let’s now look at the real-world applications of these drones within the warehouse environment.

Where Drones Fit in Inventory Audits

Drones are versatile. They’re not just for full warehouse counts; they can assist in a variety of inventory-related tasks:

- Cycle Counting: Instead of waiting for quarterly audits, drones can perform continuous cycle counts weekly or even daily, helping maintain real-time inventory accuracy.

- Stock Location Mapping: Drones can help locate items faster by scanning large areas quickly, saving hours of manual searching.

- Damaged Goods Detection: Equipped with cameras, some drones can even flag visibly damaged boxes or misplaced pallets as part of their scanning routine.

- Inventory Reconciliation: By matching scanned data with WMS records, drones can spot discrepancies instantly and alert warehouse teams to take corrective action.

All of these use cases help warehouse managers get a better handle on operations – without adding more personnel or overhead. Speaking of overhead, what challenges should businesses keep in mind before going airborne with inventory?

Now that we understand what drone inventory management is, let’s explore the game-changing benefits it brings to warehouse operations.

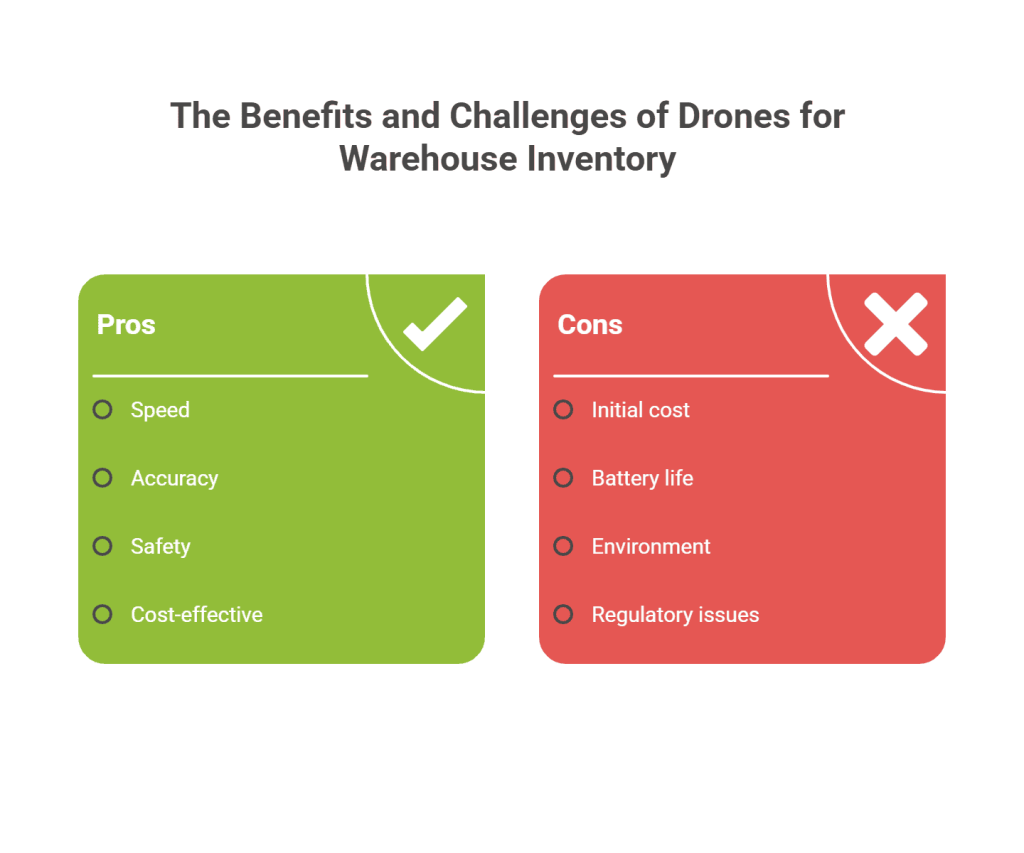

The Benefits of Drones for Warehouse Inventory

Implementing drones for warehouse inventory isn’t just about looking futuristic. It’s about solving real problems with smart automation. Here’s how drones add serious value:

- Speed Like Never Before: Manual inventory counts can take hours or even days. Drones can complete the same audit in a fraction of the time, drastically reducing downtime.

- No More Human Errors: Fatigue, misreads, and skipped items are common in manual processes. Drones use sensors and software to capture accurate data with every scan, every time.

- Improved Safety: With drones doing the heavy lifting at heights and hard-to-reach areas, workers stay on the ground, where it’s safer. No more ladders or forklifts for inventory checks.

- Cost Efficiency: Over time, drones can cut down on labor costs, reduce shrinkage, and improve data accuracy – all of which lead to a healthier bottom line.

Challenges of Drone-Based Inventory Audits

Like any tech solution, drone inventory management comes with its own set of considerations:

- Initial Investment: While the ROI can be strong, the upfront cost for drones, integration, and training can be significant for small to midsize operations.

- Battery Life & Flight Time: Most drones operate for 20–30 minutes before needing a recharge. For large warehouses, this might require a fleet working in rotation.

- Environment Limitations: Warehouses with lots of obstructions, poor lighting, or variable ceiling heights may pose challenges for drone navigation.

- Regulatory Concerns: Drones need to comply with workplace safety standards. Some regions may also have regulations for indoor UAV use.

Despite these challenges, most are solvable with the right planning, pilot testing, and software configuration. Now let’s take a quick peek into what the future holds for drones in inventory operations.

The Future of Drone Inventory Management

The future is looking even brighter and more autonomous. Here’s what we can expect next:

- AI-Driven Flight Paths: AI will soon enable drones to create their own flight paths based on historical inventory inaccuracies or high-risk areas.

- Drone Swarms: Multiple drones operating in coordination can cover larger areas faster without overlapping or interfering with each other.

- Blockchain Integration: This can improve traceability and security of inventory data, especially in regulated industries like pharma or food.

- Predictive Maintenance Alerts: Drones could detect not just product issues, but also flag potential infrastructure risks like shelf misalignments or damaged racking.

With these developments, the drone isn’t just a flying scanner – it’s becoming a flying warehouse assistant.

FAQs : Why Drone Inventory Management is the Future of Warehousing

1. How much time can drones save during an audit?

Depending on the warehouse size, audits that typically take days can be done in just a few hours using drones.

2. Can drones operate in dark or low-light warehouses?

Yes, many drones are equipped with infrared or low-light cameras to function in dimly lit environments.

3. Are drones suitable for all warehouse sizes?

Drones are most effective in mid to large-scale warehouses where manual inventory is more time-consuming and physically demanding.

4. What industries are adopting drone warehouse inventory first?

Retail, e-commerce, pharmaceuticals, and 3PLs are early adopters due to their scale and need for accurate, frequent inventory audits.

5. Can drones detect errors or just scan inventory?

Some advanced drone systems use AI to detect errors like duplicate inventory, wrong SKUs, or even damaged items.

Conclusion

Drone inventory management is reshaping the very foundation of how warehouses operate.

These nimble, flying assistants are cutting down audit times, improving data accuracy, and reducing safety risks. As costs drop and capabilities expand, drones will become an integral part of warehouse inventory operations – not a luxury, but a necessity.

It’s not about replacing humans. It’s about giving them smarter tools. And in today’s fast-paced, accuracy-obsessed supply chain world, drones might just be the best co-pilot a warehouse can have. Contact QodeNext today and experience the benefits firsthand!