Walking into a poorly organized warehouse can feel like navigating a maze—rows of racks packed with products, but no clear way to find what you need. This lack of structure slows down operations, leads to errors, and frustrates workers.

Rack labeling solves this. With clear, consistent shelf labels, warehouses become faster, more accurate, and easier to manage. In fact, studies show a 30% boost in productivity when rack labels are used effectively. This guide will share smart labeling ideas to help streamline your warehouse.

The Importance of Rack Labels in a Warehouse

A well-organised warehouse is the backbone of any successful business, and rack labels play a crucial role in achieving this goal. Rack labels help identify storage locations, making it easier for warehouse staff to locate products quickly and accurately. This not only minimises picking errors but also reduces the time spent searching for items, ultimately boosting productivity.

Additionally, proper labelling is essential for inventory management and stock rotation. By clearly labelling the shelves, it becomes easier to track inventory levels, know when to restock, and ensure that older items are picked first (First-In-First-Out method). This leads to a reduction in waste and spoilage, particularly for perishable goods.

Rack Label Ideas to Improve Warehouse Efficiency

1.Colour-Coded Labels

Assign specific colours to different product categories or storage zones. For example, use blue labels for electronics, red labels for clothing, and green labels for household items. Colour-coding provides an instant visual cue to warehouse staff, allowing them to quickly identify and navigate to the desired items.

2.Barcode and QR Code Labels

Implement barcode or QR code labels for each shelf. These codes can be scanned using handheld devices, making inventory management and tracking a breeze. The use of technology in rack labelling ensures real-time updates, reducing human errors and data inaccuracies.

3.Magnetic Strip Labels

Magnetic strip labels are versatile and easily movable. They can be attached to metal shelves, racks, or even the floor. This flexibility allows you to adjust and reorganise your warehouse layout efficiently without leaving behind any adhesive residue.

4.Dual-Sided Labels

Improve visibility by using dual-sided rack labels. This way, no matter which side of the aisle warehouse staff is on, they can quickly identify the products and their details, reducing confusion and saving time.

5.Vertical Hanging Labels

Make use of vertical space by using hanging labels that extend down from the racks. These labels are particularly useful for long aisles, as they make it easier to spot the right products from a distance.

Essential Tips for Labeling Shelves in Your Warehouse

When labelling shelves in your warehouse, there are several essential guidelines to follow for optimal results:

- Consistency: Ensure consistency in the label placement and format throughout the warehouse. This consistency will make it easier for staff to understand and adapt to the labelling system.

- Clear and Readable Font: Use a clear and readable font for the labels. Avoid fancy or intricate fonts that may be difficult to decipher, especially in dimly lit areas of the warehouse.

- Size Matters: The size of the labels should be large enough to read from a reasonable distance. Consider the viewing distance within your warehouse and select the appropriate label size accordingly.

- Maintenance: Regularly inspect and maintain the rack labels. Labels that are faded, damaged, or peeling should be promptly replaced to avoid confusion and errors.

- Employee Training: Properly train warehouse staff on the use and importance of rack labels. Familiarity with the labelling system will ensure efficient operations and minimise errors.

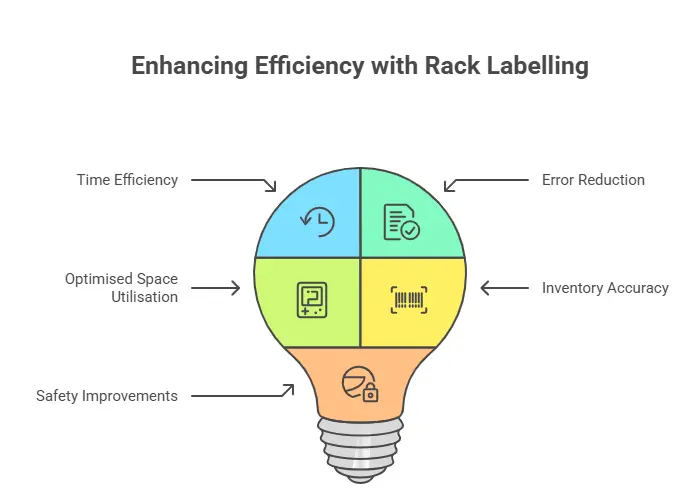

Key Advantages of Effective Rack Labelling

- Time Efficiency: Well-labelled shelves enable faster order picking and reduce the time spent searching for products, leading to an increase in overall productivity.

- Error Reduction: Clear rack labels reduce the chances of picking errors, thus minimising costly mistakes and enhancing customer satisfaction.

- Optimised Space Utilisation: With proper labelling, it becomes easier to identify and utilise all available storage space efficiently, maximising the warehouse’s capacity.

- Inventory Accuracy: An organised labelling system allows for accurate inventory tracking, making it simpler to manage stock levels and reduce overstocking or stockouts.

- Safety Improvements: Labelling hazardous or fragile items appropriately ensures that they are handled with care, promoting a safer work environment.

Step-by-Step Guide to Implementing Rack Label Solutions

Once you’ve decided on the rack label ideas that suit your warehouse best, it’s time to implement them effectively:

- Planning and Layout: Before applying the labels, create a well-thought-out plan for your warehouse layout. Determine the best locations for different product categories and ensure a logical flow of goods.

- Testing: Conduct a trial run with a small section of your warehouse to test the effectiveness of the label system. Take feedback from your staff and make necessary adjustments.

- Gradual Implementation: If you’re revamping an existing warehouse, consider implementing the label system gradually to minimise disruption to ongoing operations.

- Scalability: Choose a labelling system that can adapt to your future needs. As your business grows, your warehouse requirements might change, and the labels should accommodate those changes.

Significant Challenges and Solutions

Implementing a rack labelling system may come with its challenges, but with the right approach, they can be overcome:

- Resistance to Change: Employees may resist adopting a new labelling system, fearing a learning curve. Conduct thorough training sessions and highlight the benefits of the new system to gain their buy-in.

- Label Damage: In a bustling warehouse environment, labels can get damaged or dirty. Regular maintenance and using durable materials can address this issue.

- Data Accuracy: To avoid errors in the labelling system, ensure that all product information is accurately recorded in your inventory management system.

Conclusion

Properly labelling shelves in your warehouse is a fundamental aspect of efficient inventory management and operational productivity. Implementing creative rack label ideas, such as colour-coding, barcode usage, and magnetic strips, can significantly enhance your warehouse’s overall efficiency and organisation. So, the answer to your question- how to label shelves in warehouse is simple. Factors such as consistency, readability, and employee training are essential factors to consider when implementing your labelling system.

Remember, a well-organized warehouse leads to better inventory tracking, reduced errors, and improved safety—ultimately positively impacting your bottom line. So, invest in effective rack labelling solutions to take your idea warehouse to the next level!

If you’re looking for a cutting-edge, user-friendly, and customizable warehouse management system, get in touch with us at Qodenext. Our platform is designed to streamline your warehouse operations and maximise efficiency, allowing you to focus on growing your business.

FAQs: How to Label Shelves in Warehouse

1.How often should I update my rack labels?

It’s recommended to review and update your rack labels regularly, especially when reorganizing the warehouse or introducing new product categories.

2.Can I use digital screens instead of physical labels?

While digital screens are an option, physical labels are generally more cost-effective and easier to implement. However, digital solutions could be suitable for certain high-tech warehouses.

3.What information should be included on the rack labels?

Rack labels should include product names, SKUs, barcodes, and any other relevant information that helps identify and manage inventory.

4.How do I choose the right rack label size?

Consider the distance from which the labels will be read and choose a size that is easily visible from that distance. Also, take into account the available space on the shelves.

5.Can I use different label types in the same warehouse?

Yes, you can use a combination of label types based on your warehouse’s needs and the type of products you handle.

6.What materials are best for durable warehouse rack labels?

Durable materials like laminated paper, PVC, vinyl, or polyester offer resistance to moisture, tearing, and abrasion—ideal for harsh warehouse environments.

7.How can barcode and QR code labels improve warehouse operations?

They enable quick scanning for inventory tracking, reduce human errors, support real-time updates in warehouse management systems, and speed up picking and restocking.

8.Is colour-coding effective for all types of warehouses?

Colour-coding is highly effective in warehouses with multiple product categories, zones, or departments as it provides visual cues that speed up navigation and reduce errors. However, it should be combined with other labelling methods for best results.

9.How often should warehouse rack labels be inspected or replaced?

Labels should be inspected regularly—at least quarterly—to check for wear, fading, or damage. Replace labels immediately if they become unreadable to avoid confusion.

10.Can dual-sided or vertical hanging labels really save time?

Yes, dual-sided labels enhance visibility from both sides of an aisle, and vertical hanging labels make identifying rows easier from a distance, both reducing search and pick time significantly.