Downtime doesn’t make noise, but every manufacturer feels its impact. A line stops, a machine slows, and suddenly productivity slips away. Each lost minute affects targets, delivery, and trust.

That is why shopfloor management matters. It gives manufacturers control over what happens on the floor, turning scattered processes into synchronized performance. When people, machines, and data work in sync, efficiency follows naturally.

From real-time production monitoring to lean shop floor techniques, it is about creating a floor that runs smoothly, reacts quickly, and performs consistently.

It is time to turn downtime into drive. Here are the top 7 shop floor management techniques to minimize costly stoppages:

1. Enhancing Visibility for Smarter Operations

You can’t fix what you can’t see. The first step toward reducing downtime is improving visibility across the shop floor. When teams have access to live information, small deviations can be corrected before they turn into costly halts.

Real-time production monitoring plays a crucial role here. It allows managers to track output rates, identify bottlenecks, and understand performance trends across lines or shifts. Combined with shop floor visibility tools, it gives decision-makers the data they need to act immediately rather than retrospectively.

Just like effective supply chain efficiency relies on real-time insight to stay balanced, manufacturing visibility ensures that downtime doesn’t catch anyone by surprise — it becomes measurable and manageable.

As visibility improves, the next step is ensuring reliability — and that’s where predictive maintenance comes in.

2. Predictive Maintenance: Preventing Problems Before They Happen

Once production data is visible, patterns begin to emerge. Machines start “talking” through vibration, temperature, and power data — and smart manufacturers listen. Predictive maintenance is the bridge between visibility and reliability within shopfloor management.

Instead of waiting for a breakdown, predictive systems alert teams when equipment shows signs of wear or abnormal behavior. Maintenance can then be scheduled proactively, reducing unexpected stops and extending machine lifespan.

This approach has transformed modern factories. Similar to how industrial conveyor operations detect belt wear early to avoid shutdowns, predictive maintenance gives manufacturers time to prepare, not panic.

And when machines run predictably, people can work consistently — which leads to the next pillar: standardization.

3. Standardization: Building Consistency Across Teams

A well-functioning machine can only perform as efficiently as the person operating it. Without standardized methods, even skilled workers may introduce variations that lead to inefficiencies or downtime.

That’s why clear, consistent workflows form the backbone of shopfloor management. Standard Operating Procedures (SOPs) ensure that every operator follows the same process, regardless of shift or experience. Visual instructions, quick-reference boards, and short training sessions make these procedures easy to follow.

The concept echoes the principle of pattern recognition — once consistency is established, any deviation becomes instantly visible. This predictability not only reduces downtime but also builds confidence across the team.

When people and processes align, the next step is timing — making sure every task and resource is in the right place at the right time.

4. Smarter Planning with Digital Scheduling

Even with visibility and standardized workflows, downtime can creep in through poor scheduling. Overlapping jobs, material shortages, or idle machines can easily derail an otherwise efficient operation.

Shop floor scheduling software eliminates this uncertainty by automating production planning. It sequences jobs logically, balances workloads, and adjusts schedules in real time when conditions change. The result? A smoother flow between shifts and fewer idle minutes between tasks.

This principle mirrors demand management, where smart planning keeps supply and demand in harmony. When integrated into shopfloor management, digital scheduling turns time into a measurable resource — not a guessing game.

With schedules optimized, manufacturers can focus on something deeper: improving the way work itself is done.

5. Lean Techniques: The Core of Continuous Improvement

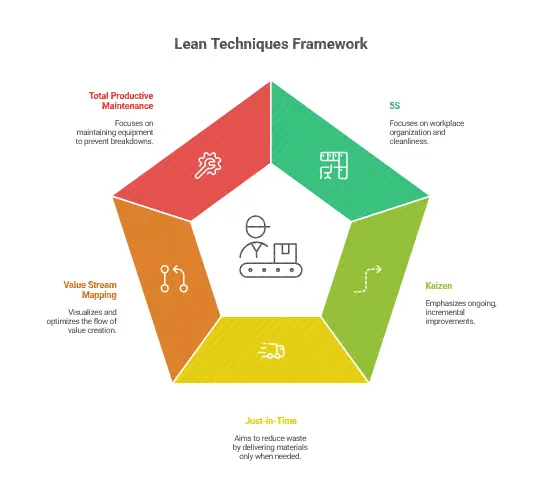

Sustained efficiency does not come from one-time efforts. It grows from small, consistent improvements made every day. Lean shop floor techniques help teams remove waste, simplify work, and make production flow smoothly.

Some of the most effective lean practices include:

1. 5S (Sort, Set in Order, Shine, Standardize, Sustain):

Keeps the workspace clean and organized, helping workers find what they need quickly and stay focused.

2. Kaizen (Continuous Improvement):

Encourages employees to share ideas for better ways of working. Small changes made regularly lead to big, lasting results.

3. Just-in-Time (JIT):

Ensures materials and parts arrive exactly when they are needed, avoiding excess storage and unnecessary delays.

4. Value Stream Mapping:

Helps identify steps in a process that do not add value, allowing teams to streamline their workflow and save time.

5. Total Productive Maintenance (TPM):

Involves operators in caring for equipment, reducing breakdowns and improving machine reliability.

When these practices become part of everyday shopfloor management, efficiency turns into a habit. People take ownership, processes stay organized, and the entire production floor moves with rhythm and purpose.

6. Using Data to Drive Decisions

Data is the language of modern manufacturing. Every machine, shift, and process generates insights — the question is how to use them.

Incorporating shop floor visibility tools into shopfloor management turns raw data into actionable intelligence. Managers can track performance trends, identify downtime causes, and compare shifts to uncover areas for improvement.

This data-driven mindset resembles cold chain logistics, where every temperature change is recorded to protect quality. On the shop floor, real-time analytics protect productivity. The result is faster, more informed decision-making — and less time lost to uncertainty.

When decisions are guided by evidence, not assumption, continuous improvement becomes sustainable.

7. Root Cause Analysis: Turning Downtime into Improvement

Even with all these systems in place, downtime can still occur — and that’s okay, as long as it leads to learning. Root cause analysis transforms downtime into an opportunity to get better.

By tagging each downtime event and categorizing its cause, shopfloor management helps teams see the bigger picture. Over time, patterns emerge: recurring delays, supplier-related issues, or specific machine inefficiencies. Tackling these root causes prevents repetition and drives long-term reliability.

Just like optimizing inventory management removes hidden bottlenecks, analyzing downtime sharpens overall performance.

With every cycle of reflection and refinement, factories move closer to zero downtime — a goal achieved not through luck, but through discipline and insight.

Comparison of Techniques and Their Impact

| Technique | How It Helps Reduce Downtime | Example | Related Topic |

| Real-Time Production Monitoring | Provides instant visibility and faster decisions | Live dashboards tracking performance | Supply Chain Efficiency |

| Predictive Maintenance | Prevents sudden equipment breakdowns | Sensor-based fault alerts | Industrial Conveyor Operations |

| Standardized Workflows | Improves consistency and reduces human error | Visual SOPs and structured training | Pattern Recognition |

| Shop Floor Scheduling Software | Balances workloads and eliminates idle time | Dynamic job sequencing | Demand Management |

| Lean Shop Floor Techniques | Removes waste and stabilizes operations | Kaizen and Just-in-Time | Stock Rotation |

| Shop Floor Visibility Tools | Enhances transparency and collaboration | Centralized performance dashboards | Cold Chain Logistics |

| Root Cause Analysis | Prevents recurring downtime through insights | Data-tagged downtime analysis | Inventory Management |

Conclusion

Reducing downtime isn’t about working harder — it’s about working smarter. With the right shopfloor management strategy, manufacturers can turn uncertainty into predictability, data into direction, and processes into progress.

By aligning real-time production monitoring, shop floor scheduling software, and lean shop floor techniques, production floors become more transparent, agile, and resilient.

Ultimately, shopfloor management isn’t just a system — it’s a mindset of continuous improvement that keeps operations running today and prepares them for tomorrow.

FAQs(Frequently Asked Questions)

1. What is shopfloor management in manufacturing?

It’s a system for monitoring, controlling, and improving production processes to reduce downtime and boost efficiency.

2. How does real-time monitoring reduce downtime?

It offers instant visibility into performance, helping managers act quickly when issues arise.

3. Why is predictive maintenance essential?

It detects wear and potential failures early, allowing maintenance before a breakdown occurs.

4. What are lean shop floor techniques?

They focus on removing waste, improving flow, and encouraging continuous small improvements.

5. Can small factories use shop floor scheduling software?

Yes. Scalable scheduling tools help even smaller facilities manage time and resources efficiently.

6. Why is downtime analysis important?

It turns interruptions into opportunities for learning and long-term performance improvement.