Warehouse slotting improves order accuracy, reduces labour costs, and maximises space utilisation. It’s the process of strategically organising inventory within a warehouse to streamline operations and enhance productivity. Whether you’re running an eCommerce fulfilment centre, a retail distribution hub, or a third-party logistics (3pl) operation, efficient slotting can significantly boost your bottom line.

In this blog, we’ll explore the top 10 strategies to help you implement smart and effective slotting in your facility.

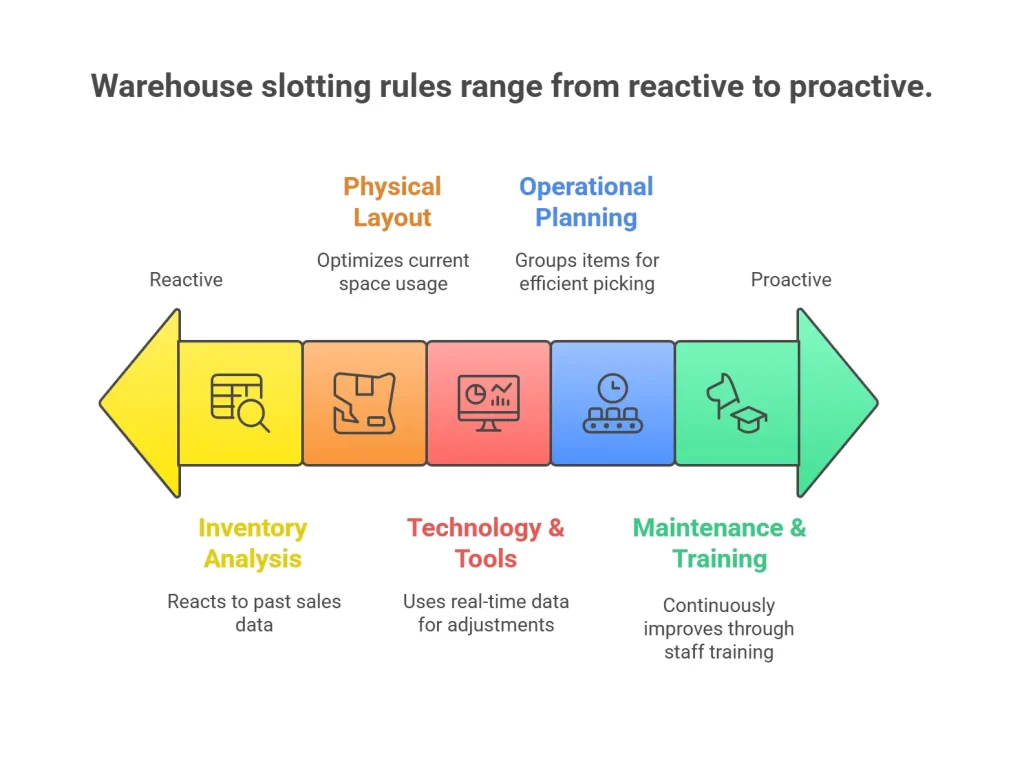

Warehouse Slotting Rules Checklist

Before implementing or reviewing your inventory slotting strategy, it’s essential to create a practical checklist to ensure every key element is covered. This helps align slotting decisions with your warehouse layout, labor resources, and operational goals.

Here’s a comprehensive product slotting checklist to guide your process:

1) Inventory Analysis

- Classify SKUS using ABC analysis based on velocity

- Identify top-performing and slow-moving items

- Determine seasonal or promotional demand variations

2) Physical Layout and Ergonomics

- Map out current slotting zones and travel paths

- Designate golden zones for high-frequency picks

- Place heavier items at waist level for ergonomic picking

- Assign lightweight or low-priority items to higher or lower slots

3) Technology and Tools

- Use warehouse slotting tools or WMS with analytics

- Set alerts for stockouts, replenishment, and SKU misplacements

- Integrate real-time data to adjust slotting on the fly

4) Operational Planning

- Group items based on picking methods (e.g., pallet, case, or piece)

- Create zones for temperature-sensitive or hazardous items

- Adjust slot sizes based on replenishment frequency and SKU dimensions

- Identify critical warehouse picking practices.

5) Maintenance and Training

- Conduct regular cycle counts to ensure accuracy

- Train staff on warehouse slotting excel templates, routes, and replenishment routines

- Review and adjust slotting quarterly or during peak seasons

Following this checklist ensures that your warehouse slotting process is not only well-planned but also adaptive, safe, and efficient, making it a cornerstone of a high-performing warehouse.

10 Slotting Strategies

1. Analyse SKU Velocity and Demand Trends

The first step in warehouse optimization is understanding which SKUS (stock-keeping units) move the fastest and which move the slowest. By analyzing SKU velocity—how often a product is picked—you can assign high-velocity items to easily accessible locations near packing or shipping areas. This helps delivery operators reduce travel time and enhance order fulfilment.

Pro tip: Use ABC inventory analysis.

- A items: high frequency

- B items: moderate frequency

- C items: low frequency

Slot accordingly.

2. Group Products by Picking Method

Different items require different picking strategies. If you’re using a combination of piece-picking, case-picking, and pallet-picking, consider organising products based on their picking method.

Group similar items in the same area to simplify workflows and reduce picker confusion.

3. Leverage Slotting Software for Data-Driven Decisions

Modern warehouse slotting is no longer a manual process. Advanced slotting software analyses multiple variables such as order history, seasonal trends, SKU sizes, weights, and velocity. It provides insights to optimise product locations dynamically.

These tools help identify:

- Overstocked vs underutilised SKUS

- Hot zones (frequent activity areas)

- Replenishment needs

By using AI-driven platforms, you minimise guesswork and enhance slotting precision.

4. Consider Product Dimensions and Ergonomics

Slotting must consider physical factors like item size, weight, and fragility. Bulky or heavy items should be stored at waist level to reduce strain on warehouse workers. Light or small items can go on higher or lower shelves.

This is a smart and sustainable approach to prevent workplace injuries.

5. Zone Your Warehouse Intelligently

Creating dedicated zones in your warehouse can reduce unnecessary movement and confusion. Consider zoning by:

- Temperature (for perishables or pharmaceuticals)

- Hazard (flammable or chemical items)

- Product category or department

By keeping related products close together, you reduce pick paths and create a more organised environment.

6. Use Slotting to Improve Replenishment Efficiency

Poor warehouse slotting can cause frequent stockouts and unnecessary replenishment runs. To address this, assign slot sizes based on expected demand and restock frequency.

High-demand SKUS should have larger or double-deep bins to reduce the need for constant refilling. Slotting should strike a balance between replenishment frequency and pick frequency to reduce labour cost and inefficiencies.

7. Optimise for Seasonal or Promotional Demand

Slotting is not a one-time setup—it must adapt to changing demands. For seasonal businesses, it’s crucial to adjust slotting strategies ahead of peak periods.

Move seasonal or promotional SKUS closer to dispatch areas before high-volume periods. Once the season ends, rotate them back to slower zones.

Flexible slotting strategies help maintain picking efficiency during demand fluctuations.

8. Reduce Travel Time with Golden Zones

“Golden zones” are ergonomic locations (typically between knee and shoulder height) where pickers can retrieve items with minimal effort. Place high-velocity SKUS in these zones to reduce picker fatigue and speed up operations.

For batch or wave picking, consider creating golden zones specific to that workflow to streamline efficiency even further.

9. Maintain Slotting Accuracy with Cycle Counts

Efficient warehouse allocation depends on accurate inventory data. Conduct regular cycle counts to ensure the right SKUS are in the right slots.

Inaccurate slotting leads to mispicks, slowdowns, and customer dissatisfaction. Incorporating a routine validation process minimises these errors and keeps your slotting plan optimised.

10. Train Warehouse Staff on Slotting Logic

Even the best warehouse strategies will fail without proper execution. Train your staff on:

- Slotting layouts

- Pick path logic

- Replenishment procedures

- Equipment handling in designated zones

When everyone understands the system, execution becomes faster, smoother, and safer.

Benefits of Efficient Warehouse Layout Optimisation

When implemented correctly, an efficient warehouse plan can lead to:

- 20–30% reduction in picker travel time

- Fewer mispicks and returns

- Improved space utilisation

- Lower labour costs

- Faster order fulfilment

- Better adaptability to business changes

Conclusion

Effective warehouse slotting is a low-cost, high-impact strategy for enhancing warehouse efficiency. It influences every aspect of operations—from picker productivity to order accuracy and customer satisfaction. By implementing the ten strategies outlined above, businesses can transform their warehouse into a streamlined, high-performance facility.

With the right tools, ongoing data analysis, and staff training, inventory storage can be a game-changer in building a scalable and competitive supply chain. For further assistance, contact Qodenext today.

FAQS about Warehouse Slotting

1. What is warehouse slotting?

Warehouse optimisation is the process of organising inventory in a warehouse based on factors such as item velocity, size, weight, and picking method to enhance efficiency and productivity.

2. Why is inventory slotting important?

It helps reduce picker travel time, improves order accuracy, and maximises the use of warehouse space—ultimately improving customer satisfaction and lowering operating costs.

3. How often should warehouse strategies be reviewed?

Ideally, slotting should be reviewed quarterly or ahead of peak seasons. Regular analysis ensures alignment with current demand patterns and avoids inefficiencies.

4. Can small warehouses benefit from slotting strategies?

Absolutely. Even small facilities benefit from strategic inventory storage by reducing chaos, improving pick rates, and minimising manual errors.

5. What tools help with SKU positioning?

Warehouse Management Systems (WMS), AI-driven slotting tools, and inventory analytics platforms help automate and optimise the slotting process based on real-time data.

6. What are the golden zones in slotting?

Golden zones refer to easy-to-reach areas within shelving or racking (usually between the knees and shoulders) where high-frequency items are stored for ergonomic efficiency.

7. Does warehouse slotting need to change for different product types?

Yes, slotting strategies may differ for products that vary in size, weight, temperature requirements, or turnover rate. For example, perishable items or hazardous materials often need dedicated slots or climate-controlled zones, while high-velocity items should always be placed for easy access.

8. Can technology fully automate warehouse slotting?

While advanced WMS and AI-driven analytics can automate much of the slotting process by continuously analyzing data and suggesting optimal layouts, human oversight is still needed to handle unique situations, exceptions, and on-the-floor adjustments.

9. What are some common mistakes in warehouse slotting?

Some typical mistakes include failing to update slotting plans for demand changes, ignoring ergonomic best practices, missing out on technology benefits, and not involving warehouse staff in the process. These can all lead to inefficiencies and higher operating costs.

10. What’s the best way to train staff on new slotting strategies?

The most effective approach combines clear documentation, hands-on demonstrations, and ongoing feedback. Use visual guides for layouts, job aids for picking routes, and refresher sessions during or after peak seasons to ensure everyone understands and adopts the new system smoothly.