As eCommerce accelerates, customer expectations grow sharper, and global freight movement becomes more complex, warehouses are under mounting pressure to handle higher volumes with greater efficiency. One of the biggest pain points in this process? Truck movement.

From unpredictable wait times and congested entry gates to poor tracking of fleet performance, warehouse operations often suffer due to inefficient truck turnaround. That’s where TITO — short for Truck-In Truck-Out — emerges as a transformative solution.

This blog breaks down what it is, the common challenges it solves, the features it offers, and how different industries can benefit from adopting this system.

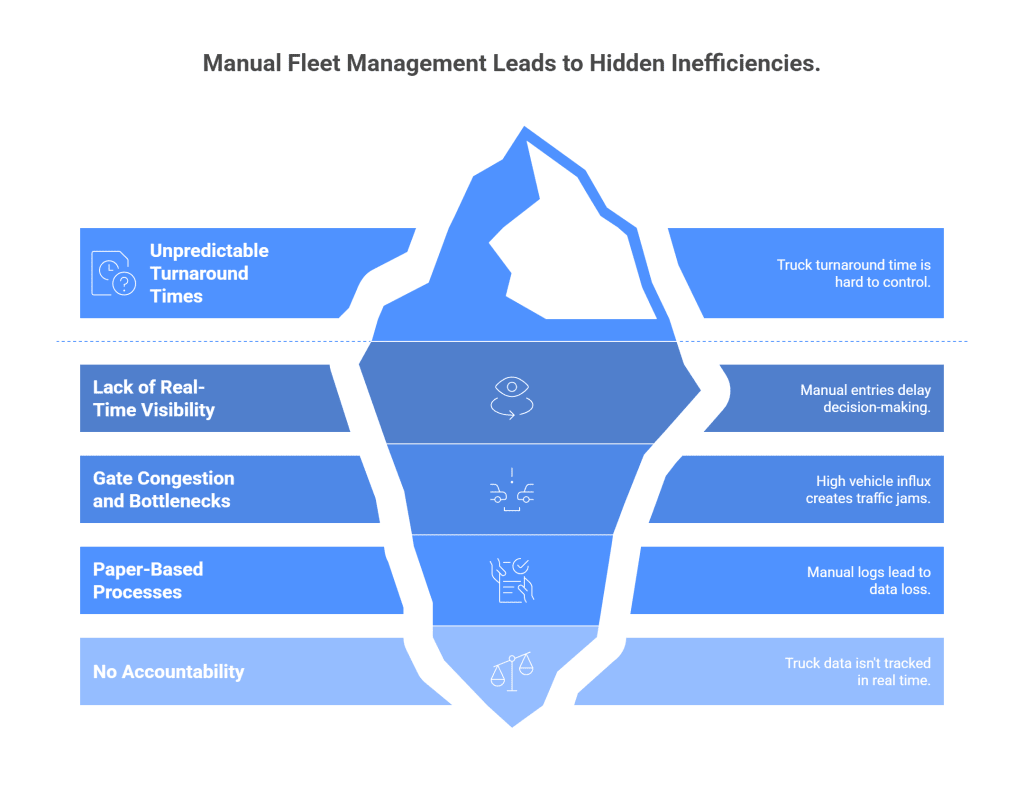

The Challenge: Manual Fleet Movement and Poor Visibility

Before understanding how TITO works, let’s examine the common problems faced by warehouse operators and logistics managers when handling truck movements:

1. Unpredictable Turnaround Times

Without a systematic approach, truck turnaround time (TAT) becomes difficult to monitor and control. Trucks may wait hours to load/unload due to poor coordination.

2. Lack of Real-Time Visibility

Most traditional systems rely on manual entries or calls to confirm a vehicle’s arrival, dock assignment, or departure — resulting in delayed decision-making.

3. Gate Congestion and Bottlenecks

A high influx of vehicles with no planned scheduling system can create traffic jams at entry/exit points, leading to chaos and increased operational costs.

4. Paper-Based Processes

Manual gate entry logs or paper passes lead to data loss, human errors, and limited traceability.

5. No Accountability

When truck data isn’t tracked in real time, it’s hard to measure carrier performance, detect delays, or identify process inefficiencies.

These fleet management challenges ultimately affect warehouse throughput, cost-efficiency, and customer satisfaction.

What is TITO?

TITO, short for Truck-In Truck-Out, is a digital solution designed to automate and optimize the entry, tracking, and exit of trucks at warehouse facilities or logistics hubs.

It provides a unified platform to manage truck movement — from gate-in to gate-out — with real-time visibility, automated timestamps, digital documentation, and performance tracking.

Think of fleet visibility as a smart access control and movement monitoring system tailored for warehouses and transportation yards.

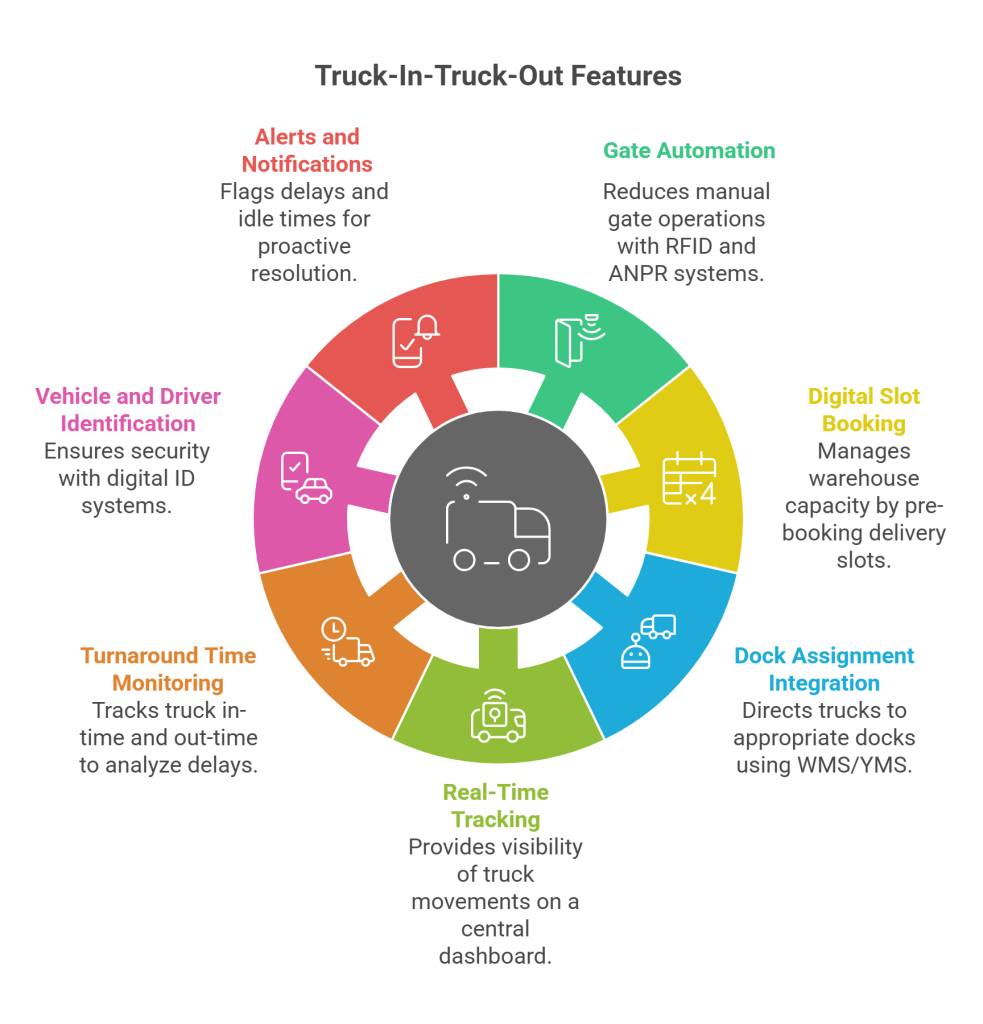

Core Features of Truck-In-Truck-Out

Here’s a breakdown of how fleet management works and the powerful features that enable faster and more controlled truck movement:

1. Gate Automation

With RFID, QR code scanners, or ANPR (Automatic Number Plate Recognition) systems, TITO automates vehicle check-in and check-out, reducing the need for manual gate operations.

2. Digital Slot Booking

Carriers or vendors can pre-book slots for delivery or pickup, helping warehouses manage capacity and avoid congestion.

3. Dock Assignment Integration

Fleet tracking can be integrated with WMS (Warehouse Management Systems) or YMS (Yard Management Systems) to direct trucks to the appropriate loading/unloading dock automatically.

4. Real-Time Tracking

Every stage of the truck’s journey — entry, movement, docking, loading/unloading, and exit — is digitally recorded and visible on a central dashboard.

5. Turnaround Time Monitoring

The system automatically logs the in-time and out-time of each truck, helping managers track TAT and analyze delays.

6. Vehicle and Driver Identification

With digital ID systems, fleet tracking ensures only authorized vehicles and personnel access the premises, improving security.

7. Alerts and Notifications

Delays, idle times, or no-shows are flagged instantly, allowing proactive resolution and better communication with stakeholders.

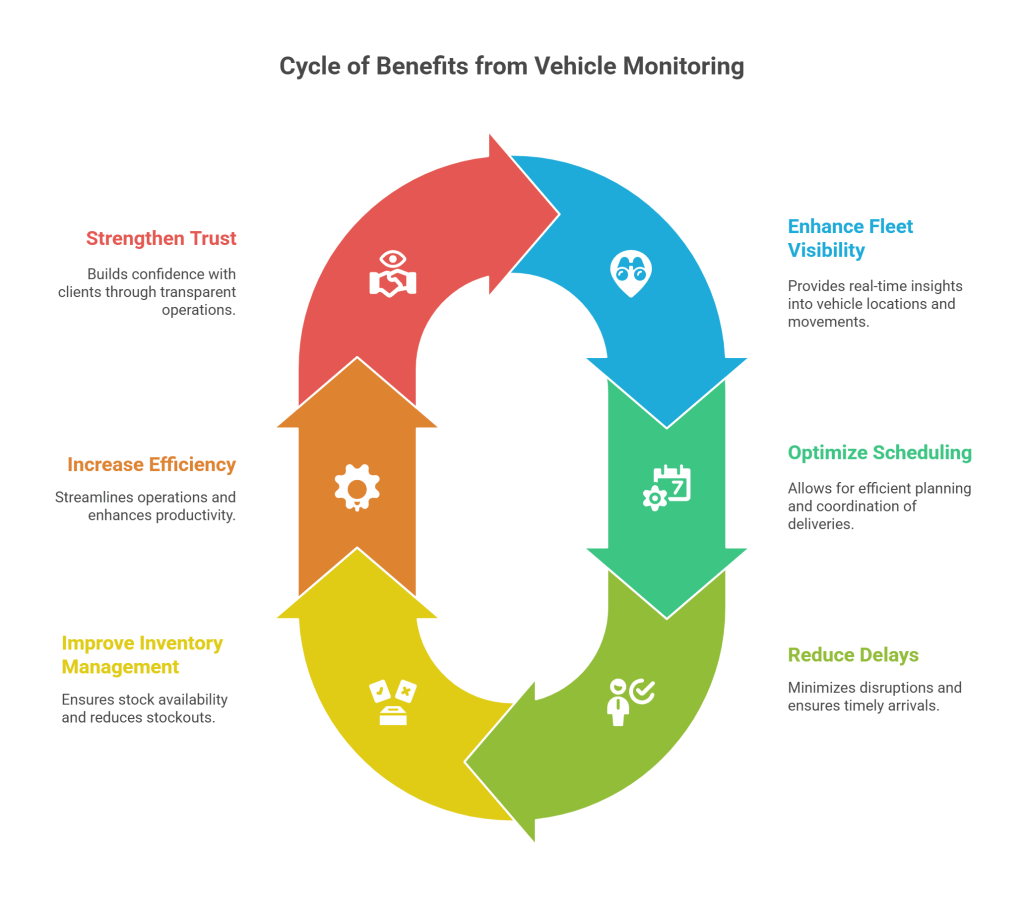

How TITO Improves Fleet Visibility

Truck-In-Truck-Out offers end-to-end visibility of truck management, which is crucial for effective logistics planning. Here’s how it delivers on that promise:

- Centralized Data Dashboard: You get a bird’s-eye view of all active and scheduled vehicles — entry/exit times, dwell time, and current location within the yard.

- Data-Driven Decisions: By identifying frequent bottlenecks or carriers with poor performance, you can optimize scheduling and resource allocation.

- Performance Metrics: It logs historical data, which can be analyzed for trends in truck delays, throughput, and loading efficiency.

- Live Communication: Integration with fleet systems and apps ensures drivers and operators receive real-time updates about gate changes or dock availability.

Ready to optimize fleet visibility? Book a free demo here: https://qodenext.com/tito/

Benefits for Truck Movement at Warehouses and Logistics

1. Reduced Dwell Time

Trucks don’t have to wait idly for a dock to become available. Pre-scheduling and real-time updates allow faster transport in warehouses.

2. Higher Throughput

With faster truck turnarounds, more vehicles can be handled in a day, increasing the operational capacity of the warehouse.

3. Improved Carrier Relationships

By minimizing waiting time and ensuring faster processing, TITO helps create smoother interactions with third-party transporters.

4. Error-Free Documentation

All entries, exits, and movements are digitally recorded, eliminating manual paperwork and reducing errors.

5. Stronger Security

Controlled access ensures only authorized vehicles and personnel enter restricted zones, reducing theft or misplacement of goods. Driver and vehicle identification through in-built RFID and ANPR cameras.

6. Lower Operational Costs

Fewer man-hours on manual gatekeeping, reduced delays, and optimized resource allocation help cut down overall logistics expenses.

7. Better Compliance

For industries requiring strict record-keeping (like pharma or food), truck tracking ensures all vehicle movements are traceable and auditable.

Industries Benefitting From Vehicle Monitoring

The beauty of TITO lies in its flexibility — it can be implemented across multiple industries, from traditional manufacturing to high-volume retail. Below are the key sectors that benefit the most from adopting fleet tracking:

1. Fast-Moving Consumer Goods (FMCG)

In the FMCG sector, speed and volume go hand in hand. Thousands of shipments move in and out of warehouses daily, and even minor delays can impact the entire distribution network.

Fleet visibility ensures faster truck movement, slot-based scheduling, and dock optimization, reducing the risk of stockouts and missed deliveries.

2. Automotive and Spare Parts

This industry involves just-in-time inventory and tight production schedules. Delayed truck movement can halt assembly lines or disrupt aftermarket supply chains.

Vehicle tracking provides real-time visibility into inbound and outbound parts movement, ensuring minimal downtime and better planning.

3. Pharmaceuticals and Healthcare

In pharma, compliance and timing are critical. Temperature-sensitive drugs and medical devices must move efficiently with full traceability.

Truck-In-Truck-Out supports secure, fast, and auditable truck movement while integrating with cold chain monitoring and quality assurance protocols.

4. E-Commerce Fulfillment Centers

For e-commerce giants, warehouse performance directly impacts delivery promises. Trucks must arrive, be offloaded, and exit quickly to maintain tight delivery windows. Fleet management helps optimize vehicle flow, avoid congestion during peak hours, and ensure faster fulfilment through intelligent scheduling.

5. Third-Party Logistics (3PL) Providers

3PL providers often manage multiple clients from a single location, making visibility and accountability crucial.

Transparent operations help them to serve clients with accurate vehicle logs, improved TATs, and automated reports, strengthening trust and efficiency.

6. Retail and Big-Box Stores

Retail distribution centers handle a vast assortment of SKUs across multiple transport carriers.

Vehicle optimization allows better coordination between carriers, real-time dock allocation, and smoother offloading/loading processes, ensuring shelves stay stocked without delays.

7. Cold Chain Warehousing

In cold storage facilities, reducing truck wait times is vital to maintaining temperature control and preventing spoilage.

TITO ensures faster gate movement, better queue management, and reduced time outside climate-controlled zones, protecting product integrity.

8. Industrial Manufacturing

Manufacturing units often deal with raw material inflow and finished goods outflow under tight schedules.

It enables synchronized inbound and outbound logistics by tracking material movement, helping prevent bottlenecks on the factory floor.

The Future of Smart Warehousing

As warehouses continue to adopt IoT and AI-powered tools, vehicle tracking will become more intelligent. With predictive analytics, machine learning for traffic forecasting, and integration with transportation management systems (TMS), next-generation TITO solutions will not only track but also predict delays and dynamically reroute vehicles for maximum efficiency.

Furthermore, as sustainability goals rise, fleet systems help reduce idle truck emissions by preventing long queues and unnecessary engine runtime.

FAQs: TITO and Truck Movement

1. What does TITO stand for?

It stands for Truck-In Truck-Out. It is a digital system that manages and automates the entry and exit of trucks at warehouses or logistics hubs.

2. How does fleet tracking help in reducing truck turnaround time?

It streamlines check-in/check-out processes, assigns docks digitally, and enables real-time tracking, which reduces waiting and idle time.

3. Can fleet visibility be integrated with our existing warehouse software?

Yes, most modern systems can be integrated with WMS, YMS, and ERP platforms for seamless data flow and automation.

4. Is Truck-In-Truck-Out suitable for small warehouses?

Absolutely. These systems are scalable and can be tailored for both small and large facilities, depending on traffic volume and complexity.

5. Does fleet tracking require a major infrastructure overhaul?

Not necessarily. Some solutions use cloud platforms and mobile devices, minimizing the need for extensive hardware or changes.

6. What technologies does TITO use for truck and driver identification?

TITO systems typically use technologies like RFID tags, QR codes, or Automatic Number Plate Recognition (ANPR) cameras to identify vehicles, along with digital IDs or biometric options for driver verification. This ensures only authorized trucks and drivers access the warehouse premises.

7. How does TITO help improve security and reduce theft in warehouses?

By digitally tracking each truck’s entry, route, docking, and exit, and controlling access with identification technologies, TITO creates a secure, auditable log of all vehicle activity. This transparency deters unauthorized access, reduces theft, and holds drivers and contractors accountable.

8. Can TITO help with compliance and audits in regulated industries?

Yes, TITO keeps detailed electronic records of every truck movement, including timestamps, driver credentials, loading/unloading events, and dock assignments. This data supports regulatory compliance and makes audits or investigations faster and more accurate—especially in industries like pharma, food, or chemicals.

9. Does the TITO system require special training for staff or drivers?

Most TITO systems are designed to be user-friendly, with intuitive dashboards and digital passes for quick check-in/check-out. Still, a short training for warehouse staff and drivers on using mobile apps or gate scanners can help maximize adoption and minimize errors.

Conclusion

Fleet visibility and truck turnaround time have a direct impact on warehouse efficiency, cost savings, and customer satisfaction. With TITO, warehouses no longer have to rely on guesswork, manual logs, or phone calls to manage vehicle flow.

If you’re looking to modernize your warehouse operations and improve your vehicle visibility, contact Qodenext today.