Managing global supply chain networks can be challenging. How do companies track, manage, and optimise complex logistics and operations? The answer lies in supply chain analytics.

What is supply chain analytics? In this guide, we will explore its benefits, key components, importance, and how businesses can leverage it for growth.

What is Supply Chain Analytics?

Supply chain analytics is the process of collecting, analyzing, and interpreting data to optimize supply chain operations. It helps businesses make data-driven decisions regarding inventory management, demand forecasting, logistics, and supplier relationships.

By using advanced analytics techniques, such as machine learning, predictive modeling, and artificial intelligence (AI), companies can identify patterns, mitigate risks, and improve efficiency.

Example: A retail company uses supply chain analytics to predict product demand based on past sales data, weather patterns, and market trends. This helps them stock the right products at the right time, reducing overstock and shortages.

Why is Supply Chain Analytics Important?

Supply chain managers understand the importance of supply chain analytics. Here is why it is crucial in the logistics industry.

- Enhanced Decision-Making

- Provides real-time insights for better inventory and logistics management.

- Reduces uncertainty in demand planning.

- Cost Reduction

- Optimizes transportation routes and supplier selection.

- Helps minimize waste and storage costs.

- Improved Customer Satisfaction

- Ensures faster and more accurate deliveries.

- Enhances product availability, reducing stockouts.

- Risk Mitigation

- Identifies potential supply chain disruptions.

- Helps develop contingency plans for unexpected delays.

- Greater Supply Chain Visibility

- Tracks goods from production to final delivery.

- Provides end-to-end transparency for better control.

Types of Supply Chain Analytics Tools

To better understand what is supply chain analytics, let’s explore its four main types:

1. Descriptive Analytics (What Happened?)

This type analyzes past supply chain data to identify trends and performance metrics.

Example: A logistics company reviews delivery delays over the past year to find recurring issues.

2. Diagnostic Analytics (Why Did It Happen?)

Focuses on uncovering the root causes of supply chain inefficiencies.

Example: A retailer analyzes warehouse data to discover why a specific product keeps running out of stock.

3. Predictive Analytics (What Might Happen?)

Uses historical data and AI-driven models to forecast demand and potential disruptions.

Example: A manufacturer predicts future raw material shortages based on geopolitical risks and past supplier delays.

4. Prescriptive Analytics (What Should Be Done?)

Recommends optimal solutions to improve supply chain efficiency and minimize risks.

Example: AI-driven analytics suggests the best delivery route to reduce fuel costs and transit time. Predictive vs prescriptive analytics is a common topic but both are different terms.

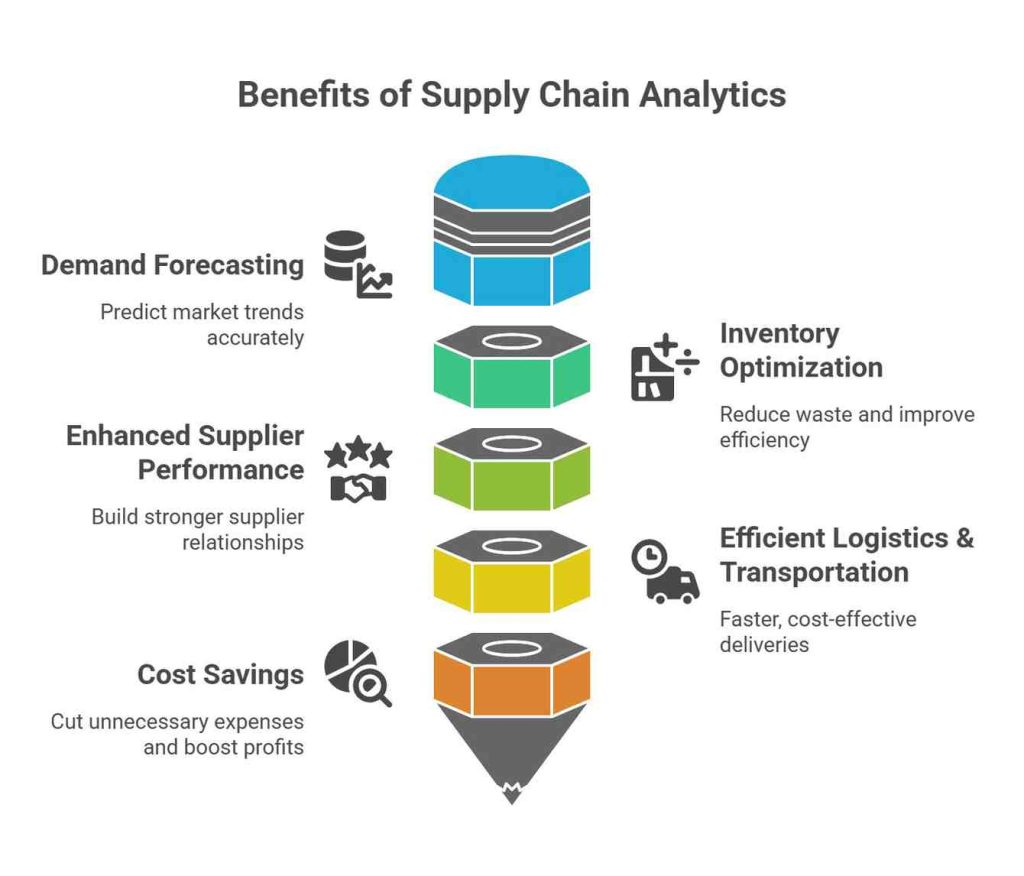

Key Benefits of Supply Chain Analytics

Now that we have covered what is supply chain analytics, let’s discuss its benefits in detail:

1. Demand Forecasting: Predict Market Trends Accurately

One of the biggest advantages of supply chain analytics is its ability to predict customer demand with high accuracy. By analyzing historical sales data, market trends, seasonal patterns, and external factors like weather or economic conditions, businesses can:

- Stock the right products at the right time to prevent shortages.

- Avoid overstocking, reducing inventory holding costs.

- Improve production planning, ensuring resources are allocated efficiently.

Example: A fashion retailer uses supply chain analytics to anticipate demand for winter clothing based on past sales, weather forecasts, and regional preferences, allowing them to stock up before peak demand hits.

2. Inventory Optimization: Reduce Waste & Improve Efficiency

Maintaining the right amount of inventory is crucial for profitability. Supply data chain analytics helps businesses:

- Identify slow-moving inventory and reduce excess stock.

- Ensure real-time inventory tracking to prevent stockouts.

- Use automated replenishment systems to keep shelves stocked efficiently.

Example: An electronics manufacturer uses real-time analytics to monitor warehouse stock levels. If a particular microchip is running low, the system triggers an automated purchase order to replenish it before it runs out.

3. Enhanced Supplier Performance: Build Stronger Relationships

Choosing reliable suppliers is critical to a smooth supply chain. Analytics provides insights into supplier performance by tracking:

- On-time delivery rates and consistency.

- Quality control metrics to ensure minimal defects.

- Cost variations to identify the most cost-effective vendors.

Example: A pharmaceutical company uses analytics to evaluate supplier reliability. If a supplier consistently delivers raw materials late, the company switches to an alternative provider to maintain production timelines.

4. Efficient Logistics & Transportation: Faster, Cost-Effective Deliveries

Transportation and logistics are among the highest cost factors in supply chains. Inventory analysis helps optimize:

- Route planning to reduce transit time and fuel costs.

- Carrier performance tracking to ensure timely deliveries.

- Real-time shipment monitoring to avoid delays and theft.

Example: A logistics company uses AI-powered analytics to suggest the fastest and cheapest delivery routes, reducing fuel costs and improving delivery times.

5. Cost Savings: Cut Unnecessary Expenses & Boost Profits

With advanced analytics in supply chain management, businesses can eliminate inefficiencies and cut costs in various areas, including:

- Minimizing operational expenses through automation.

- Reducing waste by improving demand forecasting and inventory accuracy.

- Optimizing labor allocation, ensuring workers are utilized effectively.

Example: A food processing company reduces waste by using analytics to track perishable goods, ensuring that older stock is shipped out first to avoid spoilage.

Now that you understand what is supply chain analytics, let’s delve into how you can implement it the right way.

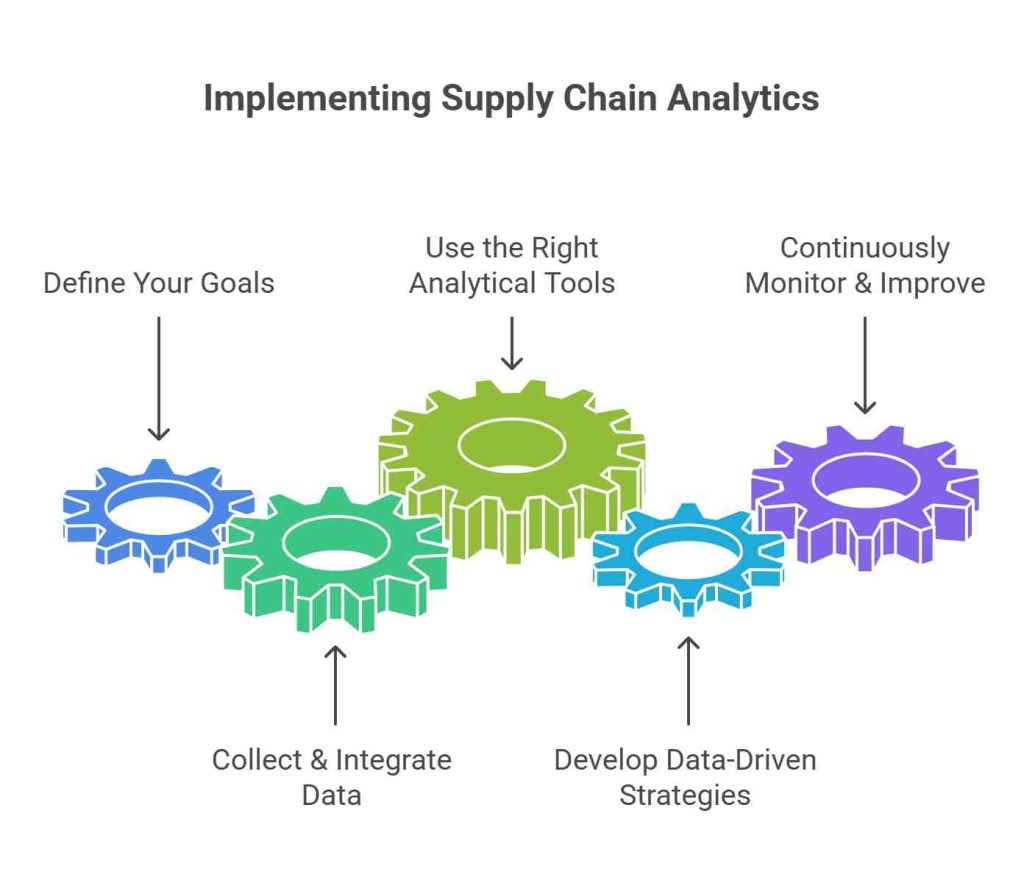

How to Implement Supply Chain Analytics?

Here’s how to implement supply chain and data analytics in your system:

Step 1: Define Your Goals

Identify key areas for improvement, such as reducing lead times, lowering costs, or improving demand forecasting.

Step 2: Collect & Integrate Data

Gather data from various sources, including ERP systems, IoT devices, and customer insights.

Step 3: Use the Right Analytical Tools

Leverage AI, machine learning, and big data tools to analyze patterns and trends.

Step 4: Develop Data-Driven Strategies

Use insights to optimize inventory, streamline logistics, and enhance supplier management.

Step 5: Continuously Monitor & Improve

Regularly update analytics models and adjust strategies based on new data trends.

Real-World Applications of Supply Chain Analytics

- Amazon – Uses AI-driven supply chain analytics to optimize warehouse operations and delivery routes.

- Walmart – Utilizes predictive analytics for demand forecasting and inventory management.

- Tesla – Leverages real-time analytics to track supply chain disruptions and adjust production schedules.

Conclusion

Understanding what is supply chain analytics is crucial for modern businesses looking to optimize operations and stay competitive. By leveraging data, AI, and automation, companies can enhance efficiency, reduce costs, and improve customer satisfaction.

Want to streamline your supply chain? Get in touch with Qodenext today.

FAQs – What is Supply Chain Analytics?

1. What is supply chain analytics, and how does it differ from traditional supply chain management?

Supply chain analytics uses data-driven insights, AI, and predictive models, whereas traditional supply chain management relies on manual tracking and historical trends.

2. Is supply chain analytics applicable across industries?

Industries like retail, manufacturing, healthcare, logistics, and eCommerce benefit the most by improving efficiency and reducing costs.

3. Can small businesses use supply chain analytics?

Yes! Many cloud-based analytics solutions are cost-effective and scalable for small businesses.

4. How does AI impact supply chain analytics?

AI improves predictive accuracy, automates demand forecasting, and enhances real-time decision-making.

5. What are the major challenges of supply chain analytics?

Common challenges include data integration issues, lack of skilled personnel, and high initial investment costs.

6. How do companies ensure data quality for effective supply chain analytics?

Companies ensure data quality by implementing robust data governance policies, regularly cleaning and validating data, and integrating information from trusted sources. High-quality data is essential for accurate analytics outcomes and better decision-making.

7. What role does cloud computing play in supply chain analytics?

Cloud computing provides scalable storage and processing power, allowing businesses to handle large datasets in real time. It also facilitates collaboration across global teams and offers access to advanced analytics tools without heavy upfront investments.

8. Can supply chain analytics help with sustainability goals?

Yes, supply chain analytics can identify inefficiencies that contribute to waste and carbon emissions. By optimizing routing, reducing excess inventory, and selecting environmentally responsible suppliers, companies can advance their sustainability and corporate social responsibility objectives.

9. How often should companies update their supply chain analytics models?

Supply chain analytics models should be updated regularly—usually quarterly or whenever significant changes in the market or operations occur—to maintain accuracy and relevance. Continuous monitoring helps businesses adapt strategies to evolving conditions.

10. What skills are essential for professionals working with supply chain analytics?

Essential skills include data analysis, statistical modeling, a strong understanding of supply chain processes, and proficiency with analytics software such as Python, R, or SQL. Additionally, domain knowledge, problem-solving abilities, and effective communication skills are vital to translating analytics into actionable business insights.