Shipping hazardous materials is a complex process that requires strict adherence to regulations, proper packaging, and thorough documentation. Whether you are transporting chemicals, flammable substances, or biological materials, understanding the shipping process ensures compliance and safety. This guide will provide a step-by-step breakdown of how to ship hazardous materials, covering regulations, packaging, labeling, and best practices.

Understanding Hazardous Materials Classification

Before diving into how to ship hazardous materials, it’s essential to classify the substances correctly. The U.S. Department of Transportation (DOT), the International Air Transport Association (IATA), and the United Nations (UN) have specific classifications for hazardous goods:

Hazard Classes

Hazardous materials are divided into nine major classes:

- Explosives – Fireworks, ammunition, and detonators.

- Gases – Compressed, flammable, or toxic gases like propane and chlorine.

- Flammable Liquids – Gasoline, ethanol, and paint.

- Flammable Solids – Matches, sulfur, and magnesium.

- Oxidizers & Organic Peroxides – Hydrogen peroxide and ammonium nitrate.

- Toxic & Infectious Substances – Pesticides, medical waste, and biological specimens.

- Radioactive Materials – Medical isotopes and uranium.

- Corrosives – Battery acid and sodium hydroxide.

- Miscellaneous Dangerous Goods – Lithium batteries and dry ice.

Understanding these classes is crucial in how to ship hazardous materials safely and legally.

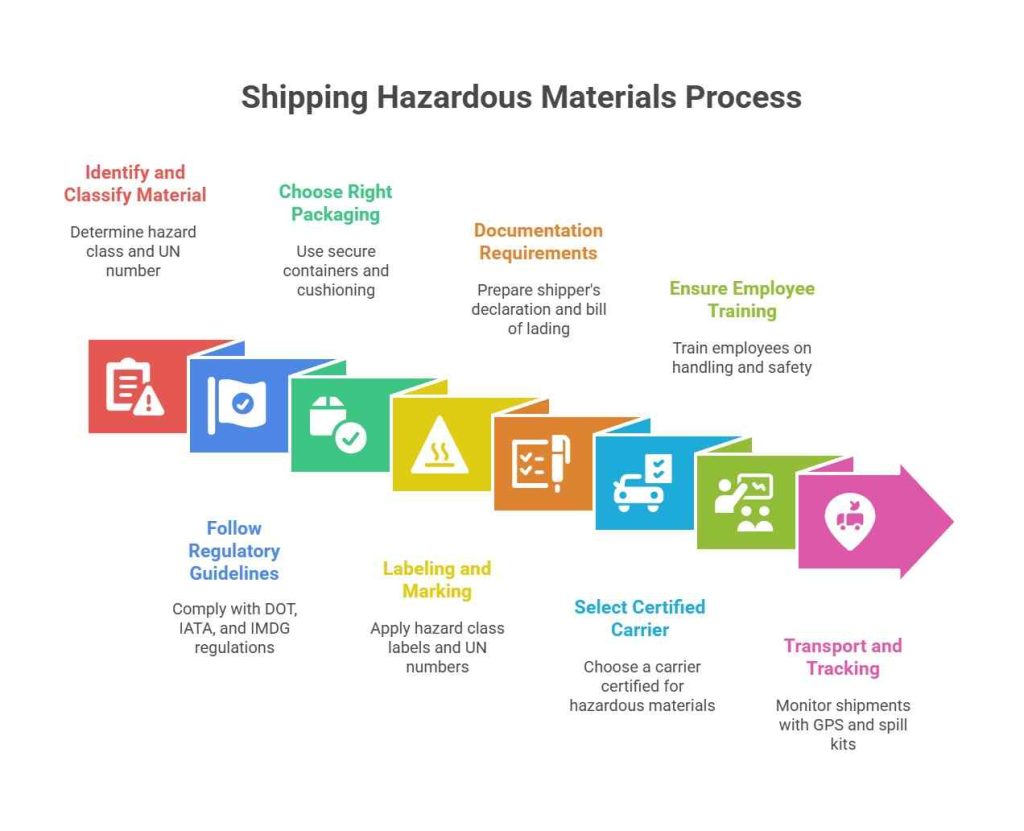

Step-by-Step Guide on How to Ship Hazardous Materials

1. Identify and Classify the Material

Determine the hazard class of your material using Safety Data Sheets (SDS).

Assign the correct UN Number, which is an international identifier for dangerous goods.

Identify the Packing Group (I, II, or III) based on the substance’s level of danger.

2. Follow Regulatory Guidelines

Domestic hazardous cargo shipping must comply with DOT regulations under 49 CFR (Code of Federal Regulations).

Air shipments must adhere to IATA Dangerous Goods Regulations (DGR).

International shipments must follow IMDG (International Maritime Dangerous Goods) Code for ocean freight.

3. Choose the Right Packaging

Proper packaging is vital in how to ship hazardous materials to prevent leaks, spills, or accidents.

- Primary Container – Ensure the substance is in a secure, leak-proof container.

- Secondary Packaging – Use cushioning material or absorbents to contain spills.

- Outer Packaging – Sturdy boxes or drums with UN-approved markings.

Example: If shipping flammable liquids, use metal or plastic drums with tight-sealing lids.

4. Labeling and Marking

Hazardous materials shipping labels must have clear, visible, and crisp markings.

- Hazard Class Label – Displays the category of the hazardous material.

- UN Number – Identifies the substance being shipped.

- Handling Instructions – Labels like “This Side Up” or “Keep Away from Heat” when necessary.

- Placards – Required for large shipments on trucks and containers.

5. Documentation Requirements

Proper documentation ensures regulatory compliance and prevents shipment delays.

- Shipper’s Declaration for Dangerous Goods – Lists the hazardous material, quantity, and emergency contact.

- Bill of Lading (BOL) – This is a written contract between the sender, carrier and the receiver.

- Emergency Response Information – Contact numbers in case of an incident.

6. Select a Certified Carrier

Not all carriers handle hazardous shipments, so choose a transporter certified in how to ship hazardous materials:

- FedEx, UPS, DHL, and specialized freight carriers transport hazardous goods under strict conditions.

- Confirm if the carrier accepts your specific hazardous materials shipping papers.

- Ensure the carrier follows training and security protocols.

7. Ensure Employee Training and Safety Compliance

The Hazardous Materials Regulations (HMR) require all employees handling hazardous shipments to be trained. Employees should complete training every three years under DOT guidelines. Training includes packaging, documentation, emergency response, and hazardous shipping certifications.

8. Transport and Tracking

- Use GPS-enabled tracking systems for real-time shipment monitoring.

- Ensure temperature-controlled shipping if the substance is sensitive to heat or cold.

- Keep emergency spill kits accessible during transportation.

Common Mistakes to Avoid When Shipping Hazardous Materials

- Incorrect Classification – Mislabeling or wrongly identifying materials leads to compliance violations.

- Improper Packaging – Weak or non-UN-certified packaging can result in leaks or fines.

- Missing Documentation – Incomplete or missing paperwork can cause shipment rejection.

- Using Unauthorized Carriers – Not all carriers are certified for hazardous goods.

- Lack of Employee Training – Employees must have up-to-date handling certification.

Best Practices for Safe and Compliant Shipping

Ensuring safe and compliant hazardous material shipping is critical for regulatory adherence and environmental protection. Here are the best practices:

1. Maintain Accurate Documentation

- Always double-check shipping manifests, Safety Data Sheets (SDS), and labels before transport.

- Keep hard and digital copies of all required forms for audits and legal compliance.

2. Use High-Quality, UN-Certified Packaging

- Choose sturdy, impact-resistant packaging that meets UN specifications.

- Use leak-proof, corrosion-resistant materials for toxic or flammable substances.

3. Follow Proper Labeling Protocols

- Ensure smart labels are legible, waterproof, and affixed to all visible sides of the package.

- Check that hazard symbols, handling instructions, and UN numbers are displayed correctly.

4. Implement Strict Safety Measures During Handling

- Use personal protective equipment (PPE) such as gloves, safety goggles, and respirators.

- Follow OSHA (Occupational Safety and Health Administration) safety guidelines when loading or unloading hazardous shipments.

5. Work with Certified and Experienced Carriers

- Partner with transporters that specialize in how to ship hazardous materials safely and efficiently.

- Verify that the carrier follows DOT, IATA, and IMDG safety protocols.

6. Regularly Train Employees on Compliance and Emergency Response

- Conduct annual refresher courses to keep employees updated on regulations.

- Organize mock emergency drills to prepare for potential hazardous spills or leaks.

7. Monitor and Track Shipments in Real-Time

- Use GPS tracking and automated alerts for high-risk shipments.

- Have a 24/7 emergency response team to handle any shipment disruptions.

Conclusion

Understanding how to ship hazardous materials is essential for regulatory compliance and safety. From proper classification and packaging to choosing the right carrier and completing documentation, every step ensures risk-free transportation. By following best practices, training employees, and staying updated on regulations, businesses can ensure safe and legal hazardous material shipping.

Do you need special guidance to resolve supply chain bottlenecks? Contact Qodenext today.

FAQs on How to Ship Hazardous Materials

1. Can hazardous materials be shipped by air?

Shipping hazardous materials by air requires strict identification, labeling, and protocol implementation. Consult with relevant authorities to follow the standard operating procedure.

2. Do I need special certification to ship hazardous materials?

Yes, businesses handling hazardous materials must comply with HAZMAT training and regulatory guidelines before shipping.

3. What happens if I ship hazardous materials without proper documentation?

Failure to comply with regulations can lead to fines, legal penalties, shipment rejection, or transport bans.

4. Can I ship hazardous materials internationally?

Yes, but international shipments must comply with IATA (air), IMDG (ocean), and country-specific regulations.

5. What are UN-certified packaging requirements?

UN-certified packaging must meet specific durability, leak resistance, and pressure tolerance standards for hazardous shipments.

6. Which shipping carriers accept hazardous materials?

FedEx, UPS, DHL, and specialized freight carriers handle hazardous shipments but require pre-approval.

7. How do I dispose of unused hazardous materials?

Unused hazardous substances must be disposed of following EPA (Environmental Protection Agency) and local hazardous waste disposal laws.

8. Do all carriers accept hazardous materials, and are there restrictions?

Not all carriers ship hazardous materials. Those that do, such as FedEx, UPS, and DHL, usually require pre-approval and compliance with specific safety and documentation protocols. Restrictions may apply to certain classes (like explosives or radioactive substances).

9. Are there specific training requirements for handling hazardous materials?

Yes, U.S. regulations require that anyone involved in shipping hazardous materials receives proper training, with recurrent training at least every three years to stay compliant.

10. Can hazardous materials be returned to the sender if refused or undeliverable?

Yes, but the return is subject to the same regulations as the original shipment to ensure safety and legal compliance.