Introduction:

In the dynamic landscape of supply chain management, staying ahead requires leveraging cutting-edge tools to enhance efficiency and streamline operations. As we approach 2024, the importance of adopting advanced supply chain management tools cannot be overstated. These tools play a pivotal role in optimizing key concepts of supply chain management, ensuring seamless processes and improved overall performance. From supply chain optimization software to operations management tools, organizations are increasingly relying on these innovations to navigate the complexities of the modern business environment.

Supply Chain Management Tools

In today’s dynamic business landscape, effective Supply Chain Management (SCM) has become the cornerstone for success. To navigate the complexities of global commerce, businesses are increasingly turning to innovative tools that streamline processes, boost visibility, and optimize overall performance. Let’s delve into the realm of Supply Chain Management tools and explore how they can revolutionize your business operations.

1.Improved Visibility:

- Supply Chain Management tools empower organizations with real-time visibility across the entire supply chain. This heightened transparency allows for better decision-making and proactive problem-solving.

- By leveraging advanced tracking and monitoring features, businesses can trace the movement of goods, identify potential bottlenecks, and ensure timely deliveries.

2.Enhanced Collaboration:

- Modern SCM tools facilitate seamless collaboration between various stakeholders in the supply chain ecosystem. From suppliers to manufacturers and distributors, everyone stays connected and informed.

- The Supply Chain Management Tools- plays a pivotal role in fostering collaboration by providing a centralized platform where data is accessible, shared, and updated in real-time.

3.Optimized Inventory Management:

- Inventory control is a critical aspect of SCM, and tools in this category offer intelligent solutions for efficient inventory management.

- With the Supply Chain Management Tools – at the forefront, businesses can automate inventory tracking, minimize excess stock, and ensure that products are readily available when needed.

4.Forecasting and Demand Planning:

- Accurate demand forecasting is essential for preventing stockouts and reducing excess inventory. SCM tools utilize advanced analytics and AI algorithms to predict future demand trends.

- Integrating Supply Chain Management Tools – into the planning process ensures that businesses can adapt swiftly to changing market demands and stay ahead of the competition.

5.Risk Mitigation:

- The global supply chain is susceptible to various risks, including geopolitical issues, natural disasters, and economic fluctuations. SCM tools offer risk management features that enable businesses to identify and mitigate potential threats.

- Through Supply Chain Management Tools – organizations can proactively assess risks, develop contingency plans, and build a resilient supply chain that can withstand unforeseen challenges.

The adoption of advanced Supply Chain Management Tools is no longer a choice but a strategic imperative for businesses aiming to thrive in today’s competitive landscape. From bolstering visibility to optimizing inventory and mitigating risks, these tools are catalysts for operational excellence. Embrace the power of SCM tools and transform your supply chain into a well-oiled, responsive, and efficient engine that drives success.

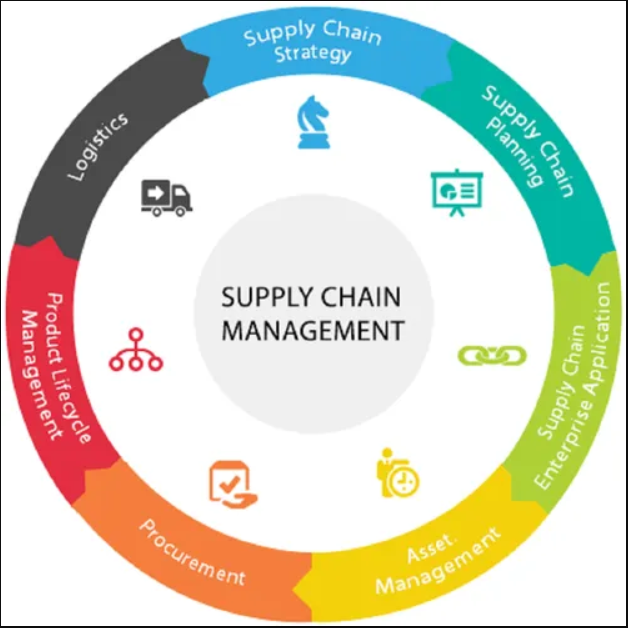

Key Concepts Of Supply Chain Management

Supply chain management is a critical aspect of modern business operations, encompassing a multitude of interconnected processes aimed at efficiently moving products or services from production to the end consumer. Understanding the key concepts of supply chain management is essential for businesses to streamline their operations and enhance overall performance. Here are the key concepts explained in detail:

1. Supply Chain Planning:

- Effective supply chain planning involves forecasting demand, setting production schedules, and managing inventory levels.

- The goal is to align supply with demand, minimizing excess inventory while ensuring products are readily available when needed.

2. Supplier Relationship Management (SRM):

- SRM focuses on developing strong partnerships with suppliers to enhance collaboration, reduce costs, and improve the overall efficiency of the supply chain.

- Establishing transparent communication channels and fostering mutually beneficial relationships are crucial components of successful SRM.

3. Logistics and Transportation:

- The physical movement of goods from suppliers to manufacturers, and ultimately to customers, involves logistics and transportation.

- Efficient transportation and logistics strategies contribute to reduced lead times and lower operational costs, contributing to overall supply chain optimization.

4. Inventory Management:

- Balancing the costs of holding inventory with the risk of stockouts is a key challenge in supply chain management.

- Utilizing advanced technologies like RFID and barcoding can enhance accuracy and visibility in inventory tracking.

5. Demand Forecasting:

- Accurate demand forecasting is crucial for optimizing inventory levels and ensuring that production meets market demand.

- Leveraging data analytics and historical trends can improve the precision of demand forecasting, minimizing the impact of uncertainties.

6. Risk Management:

- Identifying and mitigating risks is an integral part of supply chain management.

- Supply chain professionals must assess potential disruptions, such as natural disasters or geopolitical events, and implement strategies to minimize their impact.

7. Continuous Improvement:

- Embracing a culture of continuous improvement involves regularly evaluating and refining supply chain processes.

- Implementing feedback loops and learning from both successes and failures fosters adaptability and resilience within the supply chain.

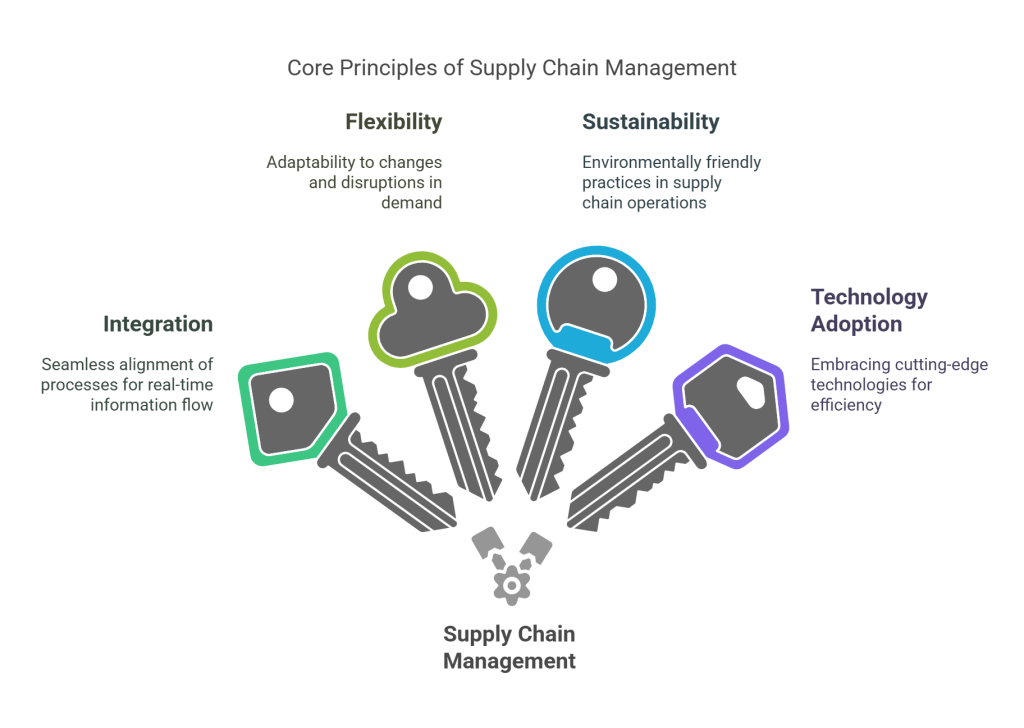

Key Concepts of Supply Chain Management:

1. Integration:

- Seamless integration of all supply chain activities ensures a holistic approach to operations.

- From procurement to distribution, aligning processes facilitates real-time information flow and enhances decision-making.

2. Flexibility:

- A flexible supply chain can quickly adapt to changes in demand or unexpected disruptions.

- Strategies such as dual sourcing and agile manufacturing contribute to increased flexibility in supply chain management.

3. Sustainability:

- Integrating environmentally friendly practices is becoming increasingly important in supply chain management.

- Sustainable sourcing, green logistics, and eco-friendly packaging contribute to a positive environmental impact.

4. Technology Adoption:

- Embracing cutting-edge technologies, such as blockchain and artificial intelligence, enhances visibility and efficiency in supply chain processes.

- Automation of routine tasks and the use of predictive analytics contribute to data-driven decision-making.

A comprehensive understanding of these key concepts is essential for businesses aiming to build resilient and efficient supply chains. By incorporating these principles into their operations, organizations can adapt to the dynamic business landscape and gain a competitive edge in the market.

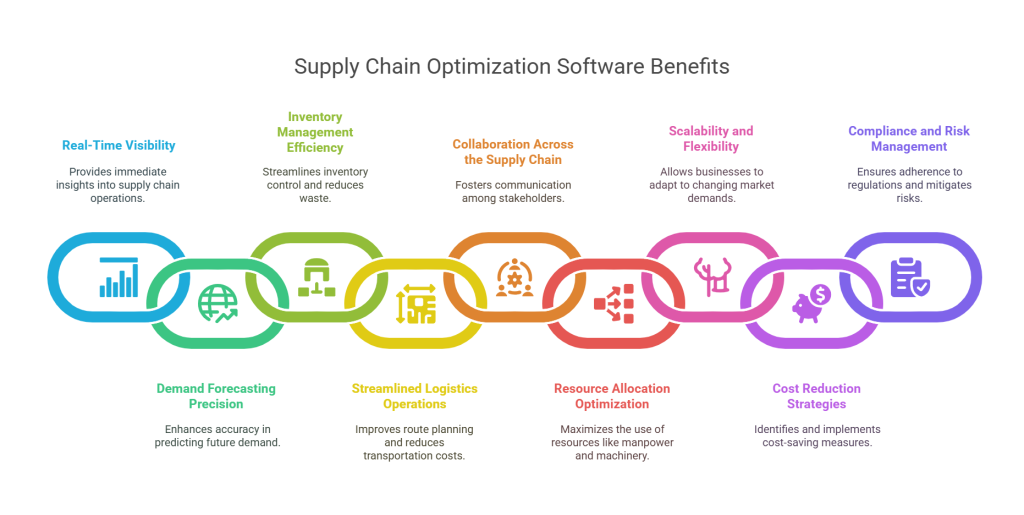

Supply Chain Optimization Software

In the fast-paced realm of modern business, maintaining a competitive edge requires more than just adaptability—it demands a finely tuned, efficient supply chain. Enter supply chain optimization software, a transformative solution that holds the potential to redefine your operational landscape. Let’s explore the diverse facets of this cutting-edge technology and how its integration can catalyze a revolution within your organization.

1. Real-Time Visibility:

- Immerse yourself in the heartbeat of your supply chain through the lens of optimization software.

- Experience the power of real-time insights, allowing for swift and informed decision-making that resonates throughout your entire operation.

2. Demand Forecasting Precision:

- Elevate your forecasting game with the precision offered by supply chain optimization software.

- Harness the prowess of intelligent algorithms, unraveling historical data and market trends to chart a course of predictive accuracy in demand forecasting.

3. Inventory Management Efficiency:

- Navigate the delicate balance of inventory levels with finesse using supply chain optimization software.

- Say goodbye to the uncertainties of stock management, as automated controls seamlessly orchestrate the ebb and flow of your inventory.

4. Streamlined Logistics Operations:

- Transform your logistics network into a symphony of efficiency through the adoption of supply chain optimization software.

- Unleash the potential for improved route planning, minimized transportation costs, and the assurance of punctual deliveries via intelligent logistics algorithms.

5. Collaboration Across the Supply Chain:

- Cultivate a culture of collaboration amongst suppliers, manufacturers, and distributors within the centralized embrace of supply chain optimization software.

- Witness the harmonious exchange of information and communication, crafting a supply chain that resonates with responsiveness and agility.

6. Resource Allocation Optimization:

- Conduct a symphony of resource allocation efficiency, orchestrating manpower, machinery, and transportation assets seamlessly.

- Employ the analytical capabilities of supply chain optimization software to fine-tune resource utilization, unveiling opportunities for operational refinement.

7. Scalability and Flexibility:

- Take center stage in the market by seamlessly adapting to its ever-evolving dynamics.

- Supply chain optimization software is not just a tool; it’s a composition of flexibility, allowing your business to scale operations in harmony with changing demands.

8. Cost Reduction Strategies:

- Conduct a thorough audit of your supply chain, uncovering opportunities for cost optimization.

- Implement strategies that resonate with cost efficiency, touching every aspect from inventory management to transportation logistics.

9. Compliance and Risk Management:

- Navigate the regulatory landscape with finesse, ensuring compliance and mitigating risks associated with disruptions.

- Proactively engage with potential risks through the lens of supply chain optimization software, crafting contingency plans that echo resilience.

The integration of supply chain optimization software is not merely a technological addition; it’s a revolution waiting to unfold within your operational framework. Embrace this transformative technology, and witness the crescendo of efficiency, cost reduction, and adaptability reverberate throughout your supply chain ecosystem. Welcome to a new era of operational excellence—fueled by the symphony of supply chain optimization software.

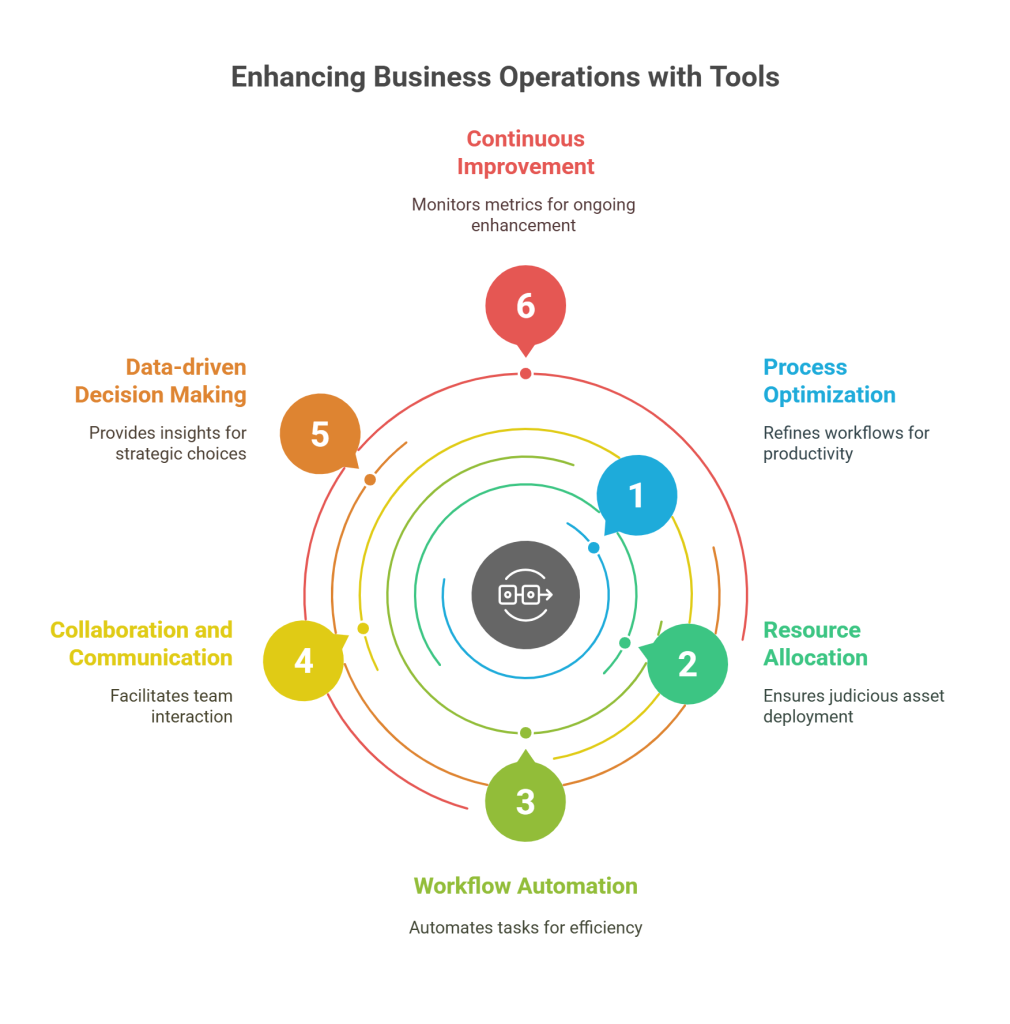

Operations Management Tools

In the dynamic realm of business operations, the strategic utilization of advanced operations management tools has emerged as a linchpin for organizations striving to streamline processes, elevate productivity, and achieve a paramount level of overall efficiency. These tools are indispensable, playing a pivotal role in managing resources, optimizing workflows, and fostering seamless collaboration across diverse departments. Let’s delve into the pivotal facets of operations management tools that render them indispensable for contemporary businesses.

1. Process Optimization:

- Operations management tools meticulously analyze and refine existing processes within an organization.

- By identifying bottlenecks and inefficiencies, these tools empower businesses to fine-tune workflows, resulting in a substantial uptick in overall productivity.

2. Resource Allocation:

- Operations management tools provide organizations with insightful, real-time data on resource utilization.

- By monitoring resource allocation, businesses can ensure that their assets are deployed judiciously, curbing unnecessary costs and fostering financial prudence.

3. Workflow Automation:

- A hallmark feature of operations management tools is their ability to automate repetitive tasks and workflows seamlessly.

- Automation not only saves invaluable time but also significantly reduces the margin for errors, contributing to a more reliable and efficient operational landscape.

4. Collaboration and Communication:

- These tools facilitate a seamless exchange of ideas and collaboration among team members, transcending geographical constraints.

- Features such as real-time messaging, file sharing, and collaborative workspaces serve as catalysts for team efficiency, fostering a connected and engaged work environment.

5. Operations Management Tools:

- The phrase “Operations Management Tools” encapsulates the essence of modernizing and optimizing business processes.

- The implementation of Operations Management Tools is a strategic imperative for organizations aiming to fortify their competitiveness in the dynamic market milieu.

- With Operations Management Tools, businesses can proactively address challenges, capitalize on growth opportunities, and steer their operations toward sustainable success.

- The versatility of Operations Management Tools renders them adaptable across diverse industries and scales of operation.

6. Data-driven Decision Making:

- Operations management tools serve as robust data repositories, offering invaluable insights for informed decision-making.

- By leveraging real-time data, businesses can make strategic decisions that translate into tangible advantages, providing a competitive edge in the market.

7. Continuous Improvement:

- These tools play a pivotal role in fostering a culture of continuous improvement by enabling organizations to monitor key performance metrics.

- Regular analysis of these metrics empowers businesses to pinpoint areas for enhancement, facilitating ongoing improvements that contribute to sustained operational excellence.

The integration of operations management tools into the fabric of business operations is a transformative stride towards achieving operational excellence. The recurring presence of the keyword “Operations Management Tools” serves as a constant reminder of the instrumental role these tools play in modernizing operations, fostering collaboration, and propelling organizations toward enduring success in a dynamic marketplace. Embracing these tools is not merely a technological evolution but a strategic imperative that positions businesses for triumph in an ever-evolving business landscape.

Conclusion:

As we step into 2024, the landscape of supply chain management is evolving, and staying competitive requires the integration of advanced tools. Qodenext, a trusted brand in the industry, stands at the forefront, offering innovative solutions that align with the key concepts of supply chain management. To optimize operations, organizations must invest in supply chain management tools, ensuring a seamless and efficient journey from production to delivery in the ever-changing business environment.

FAQs:

1. What are supply chain management tools, and why are they essential?

Supply chain management tools refer to software and technologies designed to enhance the planning, execution, and monitoring of supply chain activities. They are essential for achieving operational efficiency, cost savings, and improved customer satisfaction.

2. How do these tools contribute to the optimization of supply chain processes?

Supply chain management tools optimize processes by providing real-time visibility, automating tasks, and facilitating data-driven decision-making. This leads to improved coordination among various stakeholders and enhances overall supply chain performance.

3. Can you provide examples of key concepts of supply chain management addressed by these tools?

These tools address key concepts such as demand forecasting, inventory management, order fulfillment, and logistics coordination. By automating and optimizing these processes, organizations can achieve better resource utilization and cost-effectiveness.

4. What role does supply chain optimization software play in improving efficiency?

Supply chain optimization software utilizes algorithms and data analytics to identify areas for improvement in the supply chain. It helps organizations optimize routes, reduce lead times, and minimize costs, ultimately leading to enhanced operational efficiency.

5. How do operations management tools contribute to overall supply chain effectiveness?

Operations management tools focus on improving the day-to-day execution of supply chain activities. They enhance communication, collaboration, and resource allocation, ensuring smooth operations from manufacturing to delivery.

6. Are these tools suitable for businesses of all sizes?

Yes, supply chain management tools are designed to cater to businesses of all sizes. Whether you’re a small start-up or a large enterprise, these tools can be customized to meet the specific needs and scale of your operations.

7. How can organizations integrate Qodenext into their supply chain management toolkit?

Qodenext, a leading brand in supply chain solutions, offers a comprehensive suite of tools designed to complement and enhance existing supply chain management systems. From advanced analytics to real-time tracking, integrating Qodenext ensures a robust and future-ready supply chain.