The year 2024 is a promising one with businesses reaching sky-high predictions. But it still has a few bumps on the road, keeping everyone on their toes. With the pandemic, three years ago, supply chains had to modify themselves accordingly. Now that everything’s back to “normal”, how have certain things changed, especially in the sourcing and procurement sector?

We will explore cutting-edge strategies, industry best practices, and emerging trends shaping sourcing or procurement in supply chains. From leveraging technology to streamline processes to building relationships with suppliers, this insight provides businesses with the insights they need to move towards a more robust supply chain to make the organisation successful.

Procurement serves as the central nerve of your business, uniquely poised to foster agility within your organisation and fortify resilience across the board. Companies can achieve it through adept inventory management strategies and rigorous cost control measures.

Difference Between Sourcing and Procurement

| Aspect | Sourcing | Procurement |

|---|---|---|

| Definition | Identifies, evaluates, and selects suppliers for goods/services. | Acquires goods and services for the organization, including ordering, payment, and delivery. |

| Primary Focus | Supplier selection, negotiation, and long-term supplier relationships. | Transaction execution, order fulfillment, and supplier relationship management. |

| Key Activities | Market research, supplier evaluation, contract negotiation, risk analysis. | Purchase requisition, order placement, receipt of goods, payment processing. |

| Timeframe | Months to years (strategic/long-term). | Days to weeks (operational/short-term). |

| Goals | Reduce costs, ensure quality, build resilient supply chains. | Streamline workflows, manage supplier relationships, ensure compliance. |

| Roles | Sourcing managers, strategic sourcing specialists. | Procurement officers, purchasing managers. |

| Impact | Influences cost-efficiency and supply chain sustainability. | Affects operational efficiency, inventory, and delivery timelines. |

| Supplier Involvement | Builds and manages supplier relationships, negotiates contracts. | Leverages contracts to order, track deliveries, and manage supplier performance. |

| Feedback Loop | Uses procurement data to refine supplier selection and contracts. | Provides feedback and data to sourcing for continuous improvement. |

Sourcing refers to finding the products or services internally. Companies can do this through partnerships or joint ventures or companies. This includes buying or sourcing materials from buyers, off-the-shelf providers or even through auctions or bidding.

Global sourcing meaning also includes a longer lead time than purchasing. This means there is a waiting time for the products before you can start to use them. On the other hand, procurement refers to the process of acquiring goods and services on behalf of a business.

Supply chain players can conduct procurement by direct purchases from suppliers, intermediaries, formal contracts, or informal arrangements. The goal of purchasing is to obtain lower costs and faster delivery times. Purchasing can also involve issuing written contracts between buyers and sellers.

But that is not all, like all other aspects sourcing and procurement in supply chain management is also constantly evolving. These trends will govern how the supply chain functions and its efficiency as well.

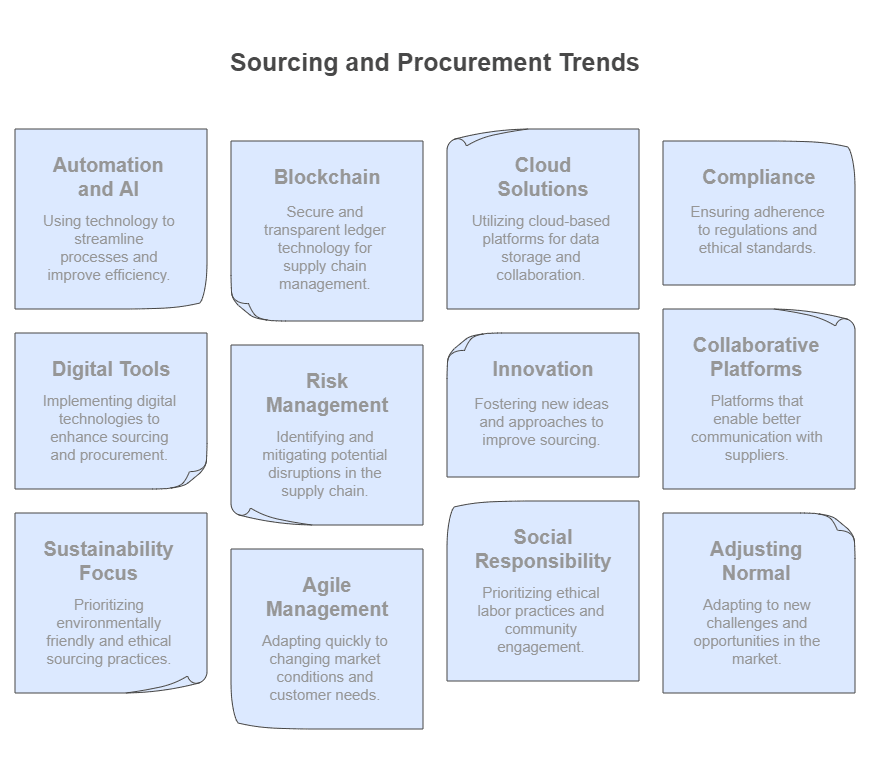

12 Key Emerging Trends in Sourcing and Procurement

Here are some of the trends of sourcing and procurement in the supply chain:

1. Automation and Artificial Intelligence

Currently, “AI” is the buzzword in the corporate sector. With Technology 4.0, AI has started to show its presence in the supply chain industry as well. Machine Learning (ML) and Robotic Automation (RPA) are the two ways that automation affects procurement. Machine learning can learn from past behaviour. This allows automation of certain tasks like inventory management and spend analytics.

RPA is a form of automation where the AI learns human behaviour. Companies can use it to automate repetitive manual tasks. For instance, the supply chain industry can automate invoice processing.

2. Blockchain

Using blockchain in procurement means that every player in the supply chain has visibility on the entire process. It also allows for the highest degree of security for the entire process. There are two applications within the blockchain like chain of custody and batch tracking that are significant to procurement.

Building trust throughout the entire supply chain speaks to the emerging importance of the Blockchain and its importance to procurement.

3. Cloud-Based Solutions

Cloud-based solutions make it easier and cheaper to handle procurement tasks. These solutions are more flexible and can grow with your needs. They also integrate better with other systems. Making sure you have plans in place to recover data if something goes wrong is crucial when using cloud solutions.

4. Compliance

Compliance is about following rules and regulations. In procurement, it means sticking to standards and controlling spending within an approved framework. This helps manage risks and ensures everything is done legally. As rules change, businesses need to be flexible and adapt their procurement policies.

5. Digital Tools

Digital tools are changing how supply chains are managed. Things like automated sourcing and predictive analytics are making processes faster and more efficient. By moving from manual to digital processes, teams can handle procurement tasks better.

These tools help manage relationships with suppliers, handle contracts, keep track of inventory, and control costs. They are the latest innovation that has transformed the sourcing and procurement process flow process in supply chains.

6. Risk Management

With the global supply chain constantly expanding, it is bound to face more risks· For this, it needs proper risk management· Risk management plays an important role in the supply chain process· It identifies, assesses and mitigates potential threats that might disrupt the flow of goods and services·

This phenomenon is there to anticipate challenges like natural disasters, supplier features or geopolitical instability· It also helps to develop strategies that can mitigate their impact·

Effective risk management ensures continuous operations, increases flexibility, and enables proactive decision-making to manage uncertainty among suppliers, distributors and stakeholders·

7. Innovation

Innovation has emerged as a critical component of procurement strategies· This has become so important that organisations are forging partnerships with suppliers to foster the development of new technologies and products aimed at enhancing profitability·

While traditional methods have historically dominated procurement practices, there’s been a noticeable shift towards embracing innovation· Sourcing and procurement in supply chains have swiftly adapted to these changing trends, poised to leverage the rapid pace of innovation in this domain·

8. Collaborative Platforms

Platforms like e-sourcing and reverse auctions enable organisations to find more efficient, cost-effective ways to source goods and services. Such platforms within the organisations allow you to govern how your procurement can undergo modernisation.

With the help of quick and easy internal communication, coupled with robust supplier communication is one of the key measures of procurement practices. Collaboration tools allow you to partner with your suppliers and internal stakeholders alike to quickly execute robust negotiations, effective fulfilment, and comprehensive spend management & analysis.

9. Increased Focus on Sustainability

Organisations prioritise sustainability. They can recognise the vital role that procurement plays in sourcing eco-friendly products and services. Environmental, Social, and Governance (ESG) practises gain prominence, crucial for investor appeal and overall organisational value. Strategic sourcing and procurement teams contribute significantly to investors’ perception of value, emphasising sustainable practices.

10. Agile Supplier Management

Given the business’s dynamic nature, agile supplier management is paramount. Understanding supplier capabilities and swiftly adapting to market shifts is essential. While originating from software development, agile principles apply to procurement, ensuring alignment with consumer needs and customer-centric decision-making. Collaboration with like-minded suppliers is crucial for success.

11. Corporate Social Responsibility Takes Center Stage

A global wave of dissatisfaction prompts a focus on corporate social responsibility (CSR). Businesses recognize the need for significant changes in environmental, employee, and community support initiatives. Adapting to these demands strengthens a business’s reputation and acceptance, while failure to do so results in declining support. Embracing CSR throughout the supply chain reflects a commitment to a fairer and more equitable world, essential for future-oriented organisations.

12. Adjusting to the New Normal

Events in 2024 highlight existing vulnerabilities and the importance of strategic planning. Sourcing and procurement face unprecedented challenges. Therefore businesses need to adapt and innovate. While uncertainties remain, proactive planning and flexibility allow companies to manage risks and take advantage of changing opportunities, allowing them to continue to thrive condition in an ever-changing

Conclusion

Companies have to navigate a complex environment of sourcing and procurement habits and processes. As the new normal unfolds, strategic planning and proactive measures are essential to success in an ever-changing environment. Consult with the experts at Qodenext.

FAQs: Mastering Sourcing and Procurement: Tactics, Trends, and Techniques

1. What is source procurement?

Sourcing procurement involves the process of identifying, evaluating, and selecting suppliers or vendors to obtain products or services needed to meet an organisation’s business needs

2. How can organisations best integrate sustainability practices into their sourcing and procurement processes?

Organisations can integrate sustainable practices by setting clear sustainability objectives, taking into account the sustainability performance of suppliers, and non-productive resources prioritising the environment, and fostering collaboration with suppliers committed to sustainable practices

3. What emerging trends in sourcing and procurement should businesses prioritise?

Trends like the digitisation of procurement processes, the adoption of advanced analytics for data-driven decision-making, and supplier diversity and practices derive priority from an emphasis on ethics to compete in the marketplace

4. What is procurement and sourcing?

Procurement is the strategic process of acquiring goods and services for a business or organization, encompassing everything from identifying needs and selecting suppliers to negotiating contracts, placing orders, and managing payments. Sourcing, on the other hand, specifically refers to the process of identifying, evaluating, and selecting suppliers who can provide the required goods or services at the best value and quality. While procurement covers the entire acquisition cycle, sourcing is the foundational step that ensures reliable and cost-effective supplier relationships are established before actual purchasing occurs.

5. What are the 7 steps of sourcing?

The seven steps of sourcing provide a structured approach to supplier selection and management. These steps are: (1) analyzing internal needs and defining the spend category, (2) researching the supply market to identify potential suppliers, (3) developing a sourcing strategy, (4) issuing requests for quotes (RFQs) or proposals (RFPs) and vetting suppliers, (5) negotiating and selecting suppliers, (6) arranging supplier integration and contract signing, and (7) managing supplier performance and ongoing relationships. This process ensures that organizations select the best suppliers and establish strong, sustainable supply chains.

6. Which comes first sourcing or procurement?

Sourcing comes first in the procurement cycle. Sourcing involves identifying and evaluating potential suppliers, negotiating terms, and selecting the best partners based on cost, quality, and reliability. Once sourcing is complete, procurement takes over to manage the transactional aspects, such as placing orders, managing contracts, and overseeing supplier relationships. In essence, sourcing lays the groundwork for procurement, ensuring that the organization acquires goods and services efficiently and cost-effectively.

7. What are the 3 main types of procurement?

The three main types of procurement are direct procurement, indirect procurement, and services procurement. Direct procurement involves purchasing raw materials, components, or goods that are directly used in the production of a company’s products. Indirect procurement covers the acquisition of goods and services that support business operations but do not become part of the final product, such as office supplies or maintenance services. Services procurement refers to hiring temporary staff, consultants, or vendors to provide specific services required by the organization.

8. What is a sourcing method?

A sourcing method refers to the approach or technique used to identify and select suppliers for goods or services. Common sourcing methods include using supplier databases or directories, issuing tenders or requests for quotations (RFQs), leveraging online marketplaces, networking with industry contacts, employing agents or brokers, and conducting reverse auctions where suppliers compete to offer the lowest price. The choice of sourcing method depends on factors such as the complexity of the requirement, the desired level of competition among suppliers, and the organization’s procurement strategy.