In the rapidly changing scenario of the supply chain, the hunt for ideal technology to optimize their operations remains a constant pursuit. On this note, RFID, or Radio Frequency Identification, has become a game-changer in supply chain management.

RFID is associated with identifying and tracking objects, conveying important information, inventory management, and many more through radio waves in modern supply chain management.

In this way, RFID has boosted operational efficiency, transparency, and accuracy in supply chain management.

From factories to retail shops, RFID readers and tags have become a boon, building the roadmap for future innovations in the world of supply chain management.

Without further delay, let’s dive into the more exciting part of the blog about RFID and its types.

All About RFID & Its Types

RFID technology uses a radio transponder that gives a signal through radio waves, which is then picked up by the radio receiver. It has three components- RFID readers, tags, and a software program (central database).

You can attach RFID tags to products, containers, vehicles, or palettes per your supply chain requirements. These tags will help you track your product and store information simultaneously. They are instrumental in distribution and warehousing as they provide you with real-time data.

These tags can be further split into active and passive- active tags continue transmitting data and contain a battery. In contrast, passive tags start transmitting data only after being scanned by the RFID reader. Perhaps RFID readers communicate through radio waves as communicators to RFID tags.

Now, you might be wondering what the work of RFID readers is. Let’s take you to that part.

As the name suggests, RFID readers read the data of RFID tags and capture it, transporting it to the central database. The data is then processed here and made accessible to the required authority.

Now, do you know about RFID Antennas? Well, RFID antennas act as a communicator between RFID readers and RFID tags. There is also an electronic product code that serves as the coding system, enabling identification and tracking of each product using RFID technology and smoother operations in supply chain management.

If you have received a clear picture of what RFID is, let us explore the benefits of using this technology in supply chain management.

RFID Use in Supply Chain Management: Applications and Benefits

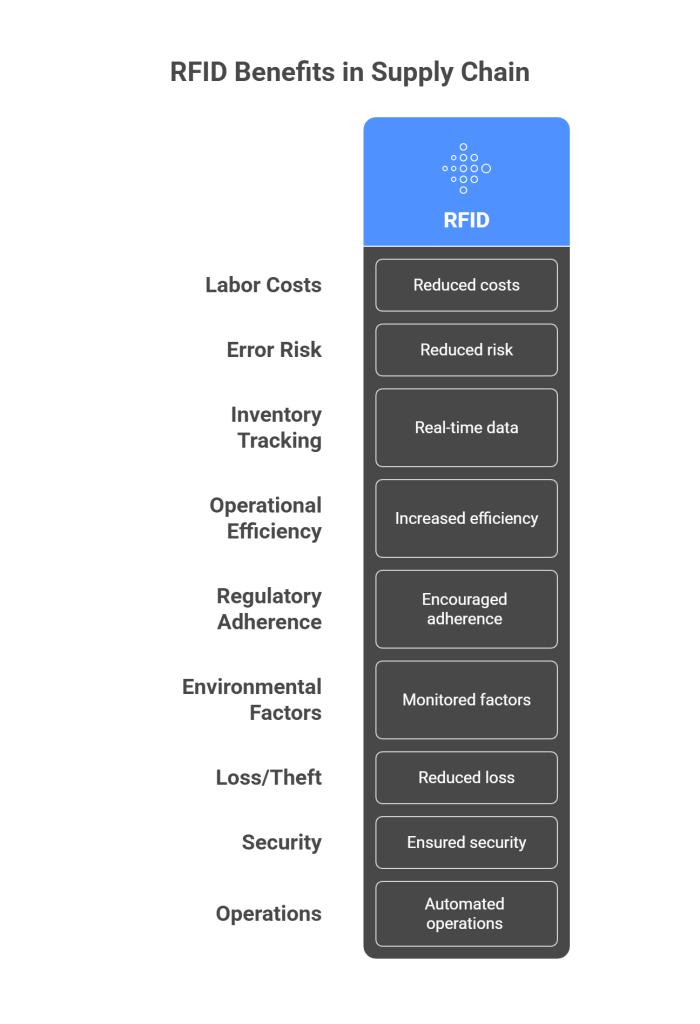

Here are some benefits of Radio Frequency Identification technology in supply chain management:

- Saving Cost of Manual Labour– RFID tags are much more advanced and more accessible than the traditional barcode system, which requires a lot of manual labour. With the advent of RFID tags, you can scan shipments quickly within a few seconds. Perhaps saving a lot of labour and time costs earlier required for inventory management.

- Reduced Risk of Errors– With RFID for tracking the details of product issues related to distributing, storing, and receiving, you can reduce the risk of human errors.

- Real-time Inventory Tracking– It also provides real-time data regarding- the location of goods, stock of goods, the performance of supply chain partners, and shipment status. This helps you improve your RFID inventory management and check that goods are always in stock whenever a customer wants them.

- Increasing Operations Efficiency- Automated data capture by RFID tends to reduce inaccuracies and misreads, ensuring reliability in the system. This leads to easy decision-making and increases the efficiency of operations.

- Encouraging Adherence to Regulations- You can monitor the product’s location and storage conditions with this tool. The handling of the products can also be verified using this information to ensure that all the rules have been followed while handling.

- Monitoring Environmental Factors- Using RFID, you can also monitor environmental factors like humidity and temperature. Using this information, you can ensure that the goods are transported safely without any damage.

- Reducing Loss or Theft- You can track your organisation’s assets, like tools, raw materials, vehicles, equipment, machinery, and other lost parts, with RFID, which prevents the risk of theft or loss.

- Ensuring Full Security- RFID can also help you track the movement of dangerous goods like explosives or harmful chemicals, ensuring high security so that products are not delivered to other locations.

- Automating Operations- From stock management, shipping labels, and packing lists to order fulfilment, RFID tags can automate several operations in supply chain management, thus making your task easier.

After learning about the applications of Radio Frequency Identification in supply chain management and also knowing about its benefits, let us explore the cons of the technology. Join us!

Cons of RFID Use in Supply Chain Management

- Intervention May Obstruct Accuracy- Sometimes metals, dirt, or sources of radio waves can block the accuracy of readings by your RFID tags.

- Higher Costs- RFID tag installation can be substantially more expensive than traditional barcodes.

- Requires More Infrastructure- A wide variety of infrastructures like scanners, data management systems, and wireless networks are needed to maintain RFID, which leads to high upfront costs.

- Question of Privacy- There might be a question of privacy concern since RFID also tracks the customers’ shopping behaviour while linking the customer’s debit or credit card number.

- Overwhelming- RFID generates a large amount of data, which you may find overwhelming for analyzing and managing.

- Required to Upgrade the Equipment- You will need scanners to recognize and register the tags automatically. Also, integration with RFID systems can be necessary for your WMS and other warehousing systems.

Now, let’s plunge into the impact of RFID on supply chain management to learn how this technology has been fruitful in this sector.

Impact of RFID On Supply Chain Management

Supply chain management has been significantly impacted by adopting RFID technology in several industries. It has changed how supply chains operate, opening up new possibilities for productivity, transparency, and flexibility.

Some significant effects are:

- Lowering operating costs as a result of optimization and automation.

- Reduced out-of-stock conditions and increased turnover of goods.

- Improved flexibility and transparency in the supply chain.

- Enhanced product tracking and compliance with regulations.

- Enhanced customer satisfaction due to proper shipment and quicker order fulfilment.

Even after getting an overview of RFID, have you not considered the future of RFID technology in supply chain management? Keep reading to find your answers!

Conclusion

With the upsurge of other technologies like AI(Artificial Intelligence), blockchains, and IoT (Internet of Things), RFID applications in supply chain management are increasing day-by-day rather than fading away.

It has become the ultimate key for maintaining efficiency, sustainability, accessibility, and resilience in supply chain management. RFID is undoubtedly leading this revolution, ushering in a new era of productive supply chain management.

Stop thinking much and grab this wonderful opportunity to use RFID technology to build a successful global supply network!

FAQs: How RFID in Supply Chain Management Works

1. What is the full form of RFID?

The full form of RFID is Radio Frequency Identification. It’s a technology that uses radio waves to read and capture information stored on a tag attached to an object, improving visibility and control in supply chain management.

2. What is the impact of RFID on the supply chain?

RFID enables real-time tracking of products, allowing quicker identification and location of items. This helps reduce costs associated with overstocking, stockouts, and inefficient manual processes. It boosts visibility, transparency, and automation across the supply chain.

3. How will RFID shape the future of logistics?

RFID is enhancing logistics by enabling faster and more accurate order picking, real-time shipment tracking, and improved delivery accuracy. These benefits result in better customer satisfaction and more agile supply chain processes.

4. How has RFID been a blessing in supply chain management?

RFID increases supply chain collaboration and visibility by automatically capturing item data and sharing it across systems. Over time, it enhances operational efficiency, improves ROI, and strengthens overall retail and logistics communication networks.

5. What are the key components of an RFID system?

An RFID system consists of three core components:

- RFID tags – attached to items to transmit data

- RFID readers – scan the tags and send the data

- A central software/database – stores and analyzes the data

Together, they create a network for tracking and managing inventory in real-time.

6. What is the difference between active and passive RFID tags?

- Active RFID tags have an internal battery and continuously broadcast signals, making them ideal for tracking high-value or moving assets over long ranges.

- Passive RFID tags do not have a power source; they rely on the reader’s signal to activate and transmit data, making them cost-effective for high-volume applications.

7. How does RFID improve inventory accuracy?

RFID offers automated, real-time data capture, eliminating manual entry errors. It ensures accurate counts, better demand planning, and improved stock visibility across warehouses and distribution centers.

8. What challenges come with RFID implementation?

Some potential drawbacks of RFID in supply chain management include:

- High initial setup costs

- Environmental interference from metal or moisture

- Privacy concerns around customer data tracking

- Large data volumes that require advanced analysis systems

- Infrastructure upgrades such as scanners and RFID-enabled WMS

9. Can RFID help reduce theft or loss in warehouses?

Yes, RFID is effective in asset tracking. It monitors the movement of tools, machinery, vehicles, and products in real time. This transparency helps prevent loss, misplacement, or theft, and ensures accountability throughout the supply chain.

10. Is RFID sustainable for long-term supply chain use?

Absolutely. RFID contributes to sustainable practices by reducing paperwork, minimizing waste from manual errors, and optimizing inventory levels. Its integration with IoT and AI technologies will further enhance energy efficiency, tracking precision, and overall supply chain resilience.