Barcodes are used extensively across multiple industries. There are various types of barcodes. However, the most widely recognized is the UPC barcode. It is most commonly used in the United States and is found on every retail product.

Now, you must be wondering, “How to create a UPC barcode?”. This article will act as a complete tutorial for you on the ways you can create a UPC barcode.

Without further ado, let’s begin with the basic definition of a UPC barcode.

What is a UPC Barcode?

Before we embark on the journey of creating a UPC barcode, let’s understand what it is. A UPC barcode, short for Universal Product Code, is a standardized 12-digit barcode used for identifying consumer products in the retail sector. Each digit in the code carries specific information about the product, making it a unique and universally recognized identifier.

Why Are UPC Barcodes Important?

UPC barcodes play a pivotal role in the retail landscape. They streamline the checkout process, enhance inventory management, and provide accurate sales data. These barcodes are not merely lines and numbers; they are the backbone of modern commerce, ensuring efficiency, accuracy, and transparency in the supply chain.

Now, that you know the basics of UPC barcodes and why they are important, let’s explore they work and the step-by-step guide on – How to create a UPC barcode.

How UPC Barcode Works

A Universal Product Code (UPC) is a 12-digit numeric code represented as a barcode using a series of parallel black lines and white spaces. Widely used in retail, logistics, and inventory management, UPCs enable efficient and accurate product tracking and identification. Understanding how a UPC functions involves examining its structure, how it’s processed at the point of sale, and its critical role in inventory systems.

1. Structure of a UPC

The UPC consists of 12 digits, each serving a specific function:

- GS1 Company Prefix: The first six to nine digits are unique identifiers assigned to a company by the GS1 organization. This prefix ensures global uniqueness and allows every product from that company to be distinguished from others.

- Item Number: Following the prefix is the product or item number, which is determined by the company. This number uniquely identifies specific products within the company’s catalog. It may vary in length based on the company’s assigned prefix.

- Check Digit: The final digit is a check digit, calculated using a defined algorithm. This digit is used to verify the accuracy of the scanned UPC and helps detect errors in barcode data.

2. How UPCs are Used at the Point of Sale (POS)

When a product with a UPC barcode is scanned at a POS terminal, the scanner reads the pattern of lines and converts it into the 12-digit code. This code is then cross-referenced with the retailer’s database to retrieve essential product information such as:

- Product name

- Price

- Internal SKU

- Promotions and discounts (if any)

This process allows for faster checkout, minimizes manual entry errors, and enhances the overall customer experience.

3. Role of UPCs in Inventory and Supply Chain Management

UPCs are vital for tracking products throughout the supply chain and for maintaining accurate inventory levels.

- Inventory Tracking: Each scan during stock movement updates the inventory levels in real-time, helping businesses monitor product availability and avoid overstocking or stockouts.

- Warehouse and Distribution: UPCs streamline warehousing by enabling barcode-based picking, packing, and verification, ensuring products are correctly handled and shipped.

- Sales Analysis and Forecasting: By analyzing sales data linked to UPCs, businesses can forecast demand, adjust inventory planning, and identify best-selling items for strategic decision-making.

UPC barcodes are a cornerstone of modern retail and logistics operations. With their standardized 12-digit format, they ensure global product identification, enhance checkout accuracy, improve inventory control, and drive operational efficiency. By understanding how UPCs work, businesses can better manage products from manufacturing through final sale.

Now, let’s move to answering the question – How to create a UPC Barcode?

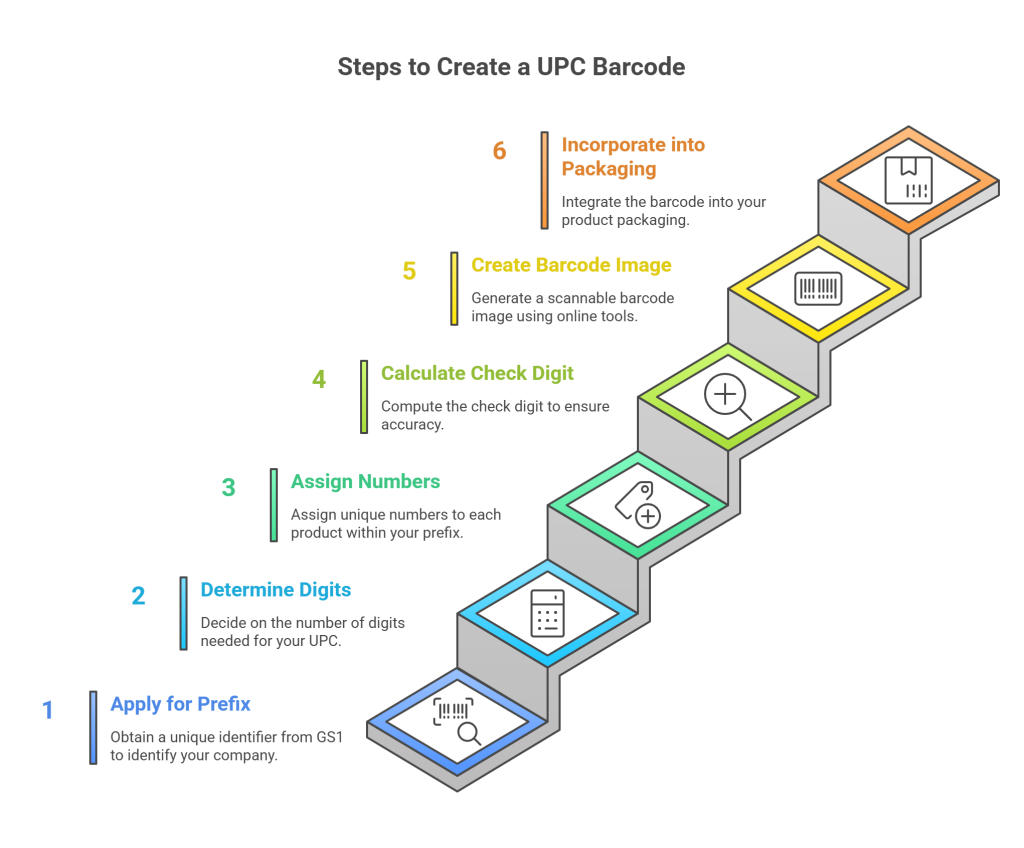

How to Create a UPC Barcode in 6 Easy Steps

1) Apply for a GS1 Company Prefix:

The first step in creating a UPC barcode is to obtain a GS1 Company Prefix. This unique identifier is assigned by GS1, the global organization that oversees barcode standards. The prefix identifies your company and ensures that each product you create has a distinct UPC.

2) Determine the Number of Digits:

Once you have your GS1 Company Prefix, decide on the number of digits you want for your UPC. While 12 digits are the standard, you may need more or fewer depending on your product’s complexity and your business requirements.

3) Assign Numbers to Products:

After obtaining your GS1 Company Prefix, assign specific numbers to each of your products. Ensure that each product has a unique identifier within your prefix to avoid conflicts.

4) Calculate the Check Digit:

The last digit in a UPC is a check digit, calculated to ensure the accuracy of the code. Numerous online tools are available to help you compute the check digit based on the other digits in your UPC.

5) Create the Barcode Image:

Use a barcode generator to convert your UPC into a scannable image. Various online tools and software allow you to input your UPC and generate a high-quality barcode image in different formats.

6) Incorporate the Barcode into Packaging:

Once you have the barcode image, incorporate it into your product packaging. Ensure that the barcode is clear, well-printed, and easily scannable by standard barcode scanners.

Furthermore, let’s check the applications of UPC barcodes.

Applications of UPC Barcodes:

UPC (Universal Product Code) barcodes are a key component in modern retail and logistics environments. Beyond their primary function of product identification, UPC barcodes serve a wide variety of applications that enhance operational efficiency, improve customer experience, and support strategic business decisions. Below are some of the most prominent applications of UPCs in business operations:

1. Point of Sale (POS) Systems

One of the most common and critical uses of UPC barcodes is in Point of Sale (POS) systems. At checkout counters in retail environments, barcode scanners read UPCs to instantly retrieve product data from a central database.

- This speeds up the transaction process, allowing for quick, error-free checkouts.

- It eliminates the need for manual price entry, thereby reducing human error.

- POS integrations automatically apply pricing, discounts, and promotions, enhancing the customer’s shopping experience.

- Accurate sales data is instantly recorded for reporting and inventory tracking.

With UPCs, store staff can focus more on customer service rather than manual data entry, which directly contributes to smoother operations and higher customer satisfaction.

2. Inventory Management

UPCs play a vital role in improving inventory accuracy and efficiency. Each product is tagged with a unique barcode, enabling automated tracking and real-time insights into stock movement.

- UPC scanning during inbound and outbound operations ensures precise inventory counts.

- Inventory management systems can use UPC data to monitor sale trends, reorder levels, and track shrinkage.

- Businesses can implement automatic replenishment triggers when stock reaches reorder points, reducing the risk of both stockouts and overstocking.

- It lowers inventory carrying costs by maintaining optimal inventory levels based on real-time demand and movement.

Overall, UPCs help in maintaining a lean, responsive inventory system that supports better decision-making and cost control.

3. Supply Chain Visibility

UPC barcodes are essential for achieving end-to-end traceability across the supply chain. From the point of manufacturing to final delivery in retail, barcodes help monitor the exact location and status of every unit.

- Each scan during shipping, receiving, or transit logs the UPC into the system, updating product status and location.

- Retailers and suppliers can identify supply chain bottlenecks or delays by tracing shipment paths.

- In case of product recalls or defects, UPCs provide a trail of distribution, making it easier to quickly identify and isolate affected products.

- Real-time supply chain data improves planning, coordination, and demand forecasting.

This level of tracking ensures not only improved efficiency but also accountability and compliance with logistics standards and regulations.

4. Marketing and Promotions

UPCs are also valuable tools in analyzing consumer behavior and supporting marketing strategies. Each scanned UPC provides quantitative data that companies can use to understand product performance.

- Retailers can track which products are selling well, analyze peak buying periods, and correlate promotions with sales uplifts.

- This data helps marketers build targeted advertising campaigns and optimize product placements within stores.

- Loyalty programs can integrate UPC data to personalize rewards or suggest related products based on purchase history.

- Manufacturers and brands can track the success of coupon or promotional offers tied to specific UPCs, measuring return on investment and customer interest.

By using UPC data to interpret consumer preferences and buying trends, businesses can develop data-driven campaigns that are more precise and effective.

Conclusion:

In conclusion, understanding how to create a UPC barcode is essential for businesses aiming to thrive in the modern marketplace. The process involves obtaining a GS1 Company Prefix, assigning unique numbers to products, calculating a check digit, and creating a scannable barcode image.

The applications of UPC barcode India span from improving the checkout experience to optimizing supply chain operations. If you want to embrace the power of UPC barcodes, connect with Qodenext today to enhance your business’s efficiency, accuracy, and overall productivity.

Also read: UPC barcode vs. EAN

Next, let’s address the frequently asked questions – How to create a UPC barcode?

FAQs – How to Create a UPC Barcode?

1. How do I get a UPC Barcode?

To obtain a UPC barcode, start by selecting the type of barcode your business needs. You must register your business with GS1 (Global Standards 1), the global organization that manages UPC standards. Once registered and the applicable fees are paid, you will receive a GS1 Company Prefix, which you can use to generate unique UPCs for your products. You can then download the barcode and print it onto product packaging or labels.

2. Are UPC and SKU the same?

No, UPC (Universal Product Code) and SKU (Stock Keeping Unit) are not the same. A UPC is a standardized 12-digit barcode used for scanning and identifying products in external-facing systems such as retail and distribution. In contrast, an SKU is an internal code assigned by businesses to track inventory, variations, or warehouse locations. Using them interchangeably can lead to errors in operations and tracking.

3. Can you convert EAN to UPC?

EAN (European Article Number) barcodes are 13-digit codes and include a country prefix, while UPCs are 12-digit codes without a country-specific indicator. You can convert UPC to EAN by adding a leading zero to the UPC if needed, but the reverse (EAN to UPC) conversion is not always feasible because EAN may contain country codes and structures that UPC systems do not support.

4. What is the difference between UPC and EAN barcodes?

UPCs are 12-digit codes primarily used in North America, while EANs are 13-digit codes used in Europe and other parts of the world. Both serve similar purposes—product identification and point-of-sale scanning—but EANs have a broader international application and may include a country code embedded in the number.

5. How to print UPC barcode labels?

You can generate and print UPC barcode labels using barcode generator tools—many of which are available online for free or as paid software. After entering your 12-digit UPC, the tool creates a barcode image, which you can download and print using a thermal printer or standard desk printer on label sheets. Ensure the resolution is high and the barcode is scannable.

6. Do I need a UPC for every product?

Yes, every unique product variation, including size, color, or model, requires its own unique UPC. This ensures that inventory, sales, and tracking systems can accurately distinguish between products and variants.

7. What is a check digit and how is it calculated?

The check digit is the last (12th) digit of a UPC code and is used for error detection when the barcode is scanned. It is calculated using a standard modulo-10 algorithm applied to the first 11 digits. Many online tools can calculate this automatically, making it easier to ensure your UPCs are valid and scannable.

8. Is it mandatory to buy UPCs from GS1?

While some barcode resellers offer UPCs at lower costs, only GS1-assigned UPCs are guaranteed to be globally unique and accepted by major retailers. For businesses intending to scale, sell in large retail chains, or maintain brand credibility, it’s highly recommended to purchase UPCs directly from GS1.

9. Can I reuse a UPC for a different product?

No, once a UPC is assigned to a specific product, it should not be reused. Reusing UPCs can cause confusion in the supply chain, lead to mismatched product data at retail, and result in non-compliance with GS1 standards.

10. What if I only sell a few products? Do I still need a GS1 prefix?

Yes, even small businesses are encouraged to obtain a GS1 Company Prefix, although GS1 now offers options like GS1 US GTIN that are more affordable for businesses needing a limited number of UPCs—perfect for startups or small product catalogs.