Your supply chain works best when everything is clear, connected, and exact. Every time you have to wait, get the wrong order, or run out of stock, it doesn’t just mess up your schedule; it also hurts your customers’ trust and your overall efficiency. If you still run your warehouse by hand, you might be spending more time fixing problems than stopping them from happening in the first place. This makes it harder to stay flexible and competitive.

That’s where a Warehouse Management System (WMS) comes in. It fills in the gaps between your planning and execution, giving every warehouse process structure, accuracy, and control. A WMS makes sure that every product moves through your supply chain quickly and on time, from keeping track of your inventory to organising your team.

As your warehouse becomes more like a digital ecosystem, it’s important to know how a WMS works so you can stay ahead of the competition. You’ll learn how to run your warehouse better, how automation is helping small businesses all over India, and how mobile barcode software lets you see everything happening on the floor in real time.

What Is Warehouse Management

When you run a warehouse, you have to plan, control, and improve every part of your business, from getting goods to storing and shipping them quickly and accurately. You want everything to go smoothly, with as few mistakes as possible and as much efficiency as possible.

But when you do things by hand, it’s easy for things to get missed. Things that are lost, orders that are late, and teams that can’t see each other well can all slow you down. That’s when automation, through a warehousing management system, makes a big difference.

A WMS lets you keep track of your inventory in real time, show your employees the best ways to get around, and give you the information you need to make better, faster decisions.

In short, good warehouse management is the key to operational excellence. A WMS makes that key a digital advantage.

The Role of a Warehousing Management System in Supply Chain Visibility

In today’s connected world, visibility drives performance. A warehousing management system brings transparency across all warehouse functions, connecting people, materials, and machines through real-time data.

It records every movement — from when goods arrive to when they leave — providing end-to-end traceability. Managers can see which orders are being processed, where stock is located, and what performance bottlenecks may appear.

By integrating a WMS with other enterprise tools, companies gain a unified view of their supply chain. This enables faster decision-making, fewer stock discrepancies, and a smoother order flow. Over time, these insights translate into measurable improvements in productivity and cost control.

When data flows seamlessly between systems, warehouse operations stop working in isolation and start functioning as a coordinated part of the larger supply chain network.

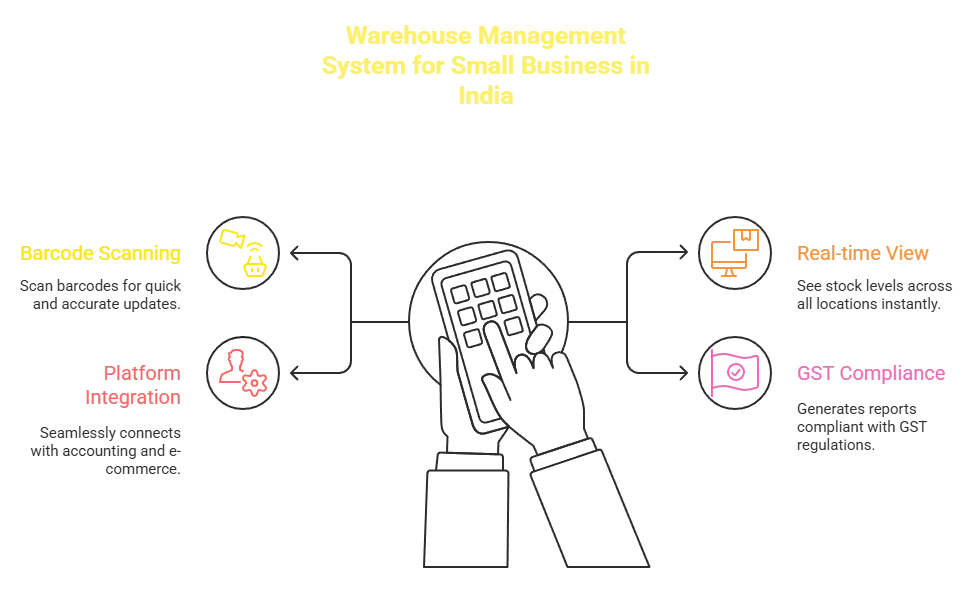

Warehouse Management System for Small Business in India

You already know the problems that come with running a small or medium business in India: not enough workers, demand that isn’t always predictable, and fierce competition. A warehouse management system for small businesses in India can help you get past these problems by making daily tasks easier without needing a lot of infrastructure or money.

Modern cloud-based WMS solutions are made with businesses like yours that are growing in mind. They are cheap, easy to set up, and can grow with your business. With the right system, you can easily keep track of multiple sales channels, automate inventory tracking, and make sure that orders are correct—all from one dashboard.

Here’s what you can get:

- Scanning barcodes to get updates faster and more accurately

- Real-time view of stocks at all locations

- Works perfectly with your accounting and e-commerce platforms

- Reports that follow GST rules and smart analytics

When you use a WMS, you get the same level of operational efficiency and control that bigger companies have. It lets you stop keeping track of things by hand and filling out forms, so you can focus on what really matters: growing your business and making your customers happier.

You can grow your business in a way that is good for the environment while still keeping the high level of service that your customers expect.

Mobile Barcode Warehousing Management Software

The way you run your warehouse has changed completely because of technology. Mobile barcode warehousing management software is one of the most important tools for changing the game. It lets you scan, keep track of inventory, and update records all from a handheld device or smartphone.

Your system automatically keeps track of inventory movement with each scan, so you don’t have to do any more manual entries or paperwork. You can see where every item is right away, from when it arrives to when it leaves.

But the advantages go beyond just speed. Mobile barcode software reduces mistakes, increases accountability, and lets you keep an eye on operations in real time, even when you’re not on the warehouse floor.

Here’s what you get:

- Tracking that is always up to date and without mistakes

- Picking and putting away things faster

- Guided workflows lead to more work getting done.

- Instant syncing between system data and warehouse activity

You can make a digital ecosystem by connecting mobile barcode tools to your warehousing management system. This way, every movement in your warehouse is instantly shown in the system. What happened? A smarter, more connected supply chain with real-time synchronisation and full visibility.

Understanding Warehousing Management System Cost per User

When you start exploring a Warehouse Management System (WMS), one of the first things you’ll likely wonder about is the warehousing management system cost per user. The truth is that there isn’t a set number. It depends on the size of your business, the modules you need, the type of deployment, and the integration needs.

A cloud-based WMS can be a good way to save money if you own a small or medium-sized business. It usually works on a subscription basis, gets automatic updates, and doesn’t need much IT help. An on-premise WMS might cost more to set up for bigger businesses, but it gives you full control over your data and customisation.

It’s better to look at the total value of the warehousing management system over time, including the efficiency gains, fewer mistakes, and ability to grow with your business, rather than just the upfront cost per user. When you think about those benefits, a WMS is more than just a piece of software you buy. It’s an investment that will pay for itself over time by making your business more productive and easier to run.

Comparison of WMS Options

| Type of WMS | Ideal For | Deployment Style | Key Advantages |

| Cloud-Based | Small and medium enterprises | Subscription-based | Quick implementationLow maintenanceRemote access from any device |

| On-Premise | Large enterprises | Local installation | Full control over dataCustomizable to business workflows |

| Hybrid | Mid-sized companies | Mix of cloud and local | Combines flexibility of cloud with local reliabilityBalanced performance and security |

How a WMS Improves Supply Chain Efficiency

A warehousing management system does a lot more than just automate tasks. It makes sure that every operation is precise and on time, so that products move smoothly from suppliers to customers.

A WMS uses algorithms for slotting, picking, and routing to cut down on travel time and make the most of available space. Forecasting tools help you better predict demand, and real-time data stops you from overstocking.

Better use of workers and warehouse space also makes things more efficient. The system assigns tasks in the best way possible based on when workers are available and makes sure that materials are stored where they can be easily reached. Because of this, productivity goes up, the time it takes to fill orders goes down, and operational costs go down a lot.

A well-implemented WMS turns the warehouse into a dynamic, self-correcting space where data drives every choice. This level of efficiency speeds up delivery, lowers operating costs, and builds customer trust, all of which are important for long-term success.

Choosing the Right Warehousing Management System

You need to be clear about your operational goals before you choose a WMS. Businesses should pay attention to how easy it is to use, how well it works with other systems, and how well it can grow. A good WMS should fit with the way you work, not make you change how you do things.

When looking at systems, think about how well they work with ERP systems, accounting software, or tools for managing transportation. Another important feature is mobile access, which is especially important for businesses that need to be able to move around in the field or warehouse.

Training and help from the vendor are both very important. A smooth onboarding process makes sure that teams can use the system correctly and keep the data accurate from the start.

Conclusion

In today’s competitive market, how quickly and accurately you move will determine your success. You can do that with a Warehouse Management System (WMS). It lets you see what’s going on in your warehouse, makes daily tasks easier, and helps you make better choices at every stage of your supply chain.

A WMS can help your small business grow without needing a lot of infrastructure. And if you have more than one facility, it makes sure that everything is the same and runs smoothly at all of them.

A WMS makes your warehouse a place of productivity and accuracy by bringing together your people, processes, and technology. This is the basis for a smarter, stronger supply chain.

FAQs(Frequently Asked Questions)

1. How does a warehousing management system support sustainability?

It reduces waste, saves energy, and promotes paperless operations.

2. Can a warehousing management system handle seasonal demand?

Yes, it adjusts inventory and staffing using demand forecasts.

3. What security features does a warehousing management system include?

It offers data encryption, role-based access, and activity tracking.

4. How does AI enhance a warehousing management system?

AI predicts demand, minimizes errors, and improves efficiency.

5. Can a WMS be customized for specific industries?

Yes, it can be tailored for sectors like pharmaceuticals, retail, or e-commerce.

6. How is the ROI of a warehousing management system measured?

By tracking order accuracy, fulfillment speed, and cost savings.

7. Does implementing a warehousing management system disrupt daily operations?

No, cloud-based systems integrate easily with existing tools.

8. Can a WMS integrate with ERP or e-commerce platforms?

Yes, most modern systems integrate seamlessly with ERP, CRM, and online sales channels, ensuring consistent and accurate data flow across departments.