HML analysis in inventory management is used to identify stock based on annual consumption. It classifies products based on their demand value, helping you allocate resources efficiently. Let’s explore the HML technique and its impact on your manufacturing product line-up.

What is HML Analysis in Inventory Management?

The HML analysis full form is High, Medium, and Low. It’s an inventory management process that categorizes items based on unit price, helping organizations prioritize efforts and optimize inventory costs. It categorizes inventory items based on their unit price, helping organizations prioritize their efforts and optimize inventory costs. Unlike ABC analysis, which considers consumption value, HML analysis solely focuses on unit price, making it an excellent tool for industries where cost management is paramount.

How Does HML Analysis in inventory management Work?

HML analysis in inventory management is straightforward yet insightful. Here’s how it works:

Data Collection

Gather data about inventory items, including their unit prices and quantities.

Sorting

Arrange items in descending order of unit price.

Classification

Divide the items into three categories:

- High (H): Items with the highest unit price.

- Medium (M): Items with moderate unit price.

- Low (L): Items with the lowest unit price.

Analysis

Evaluate the categories to determine strategies for procurement, stocking, and usage.

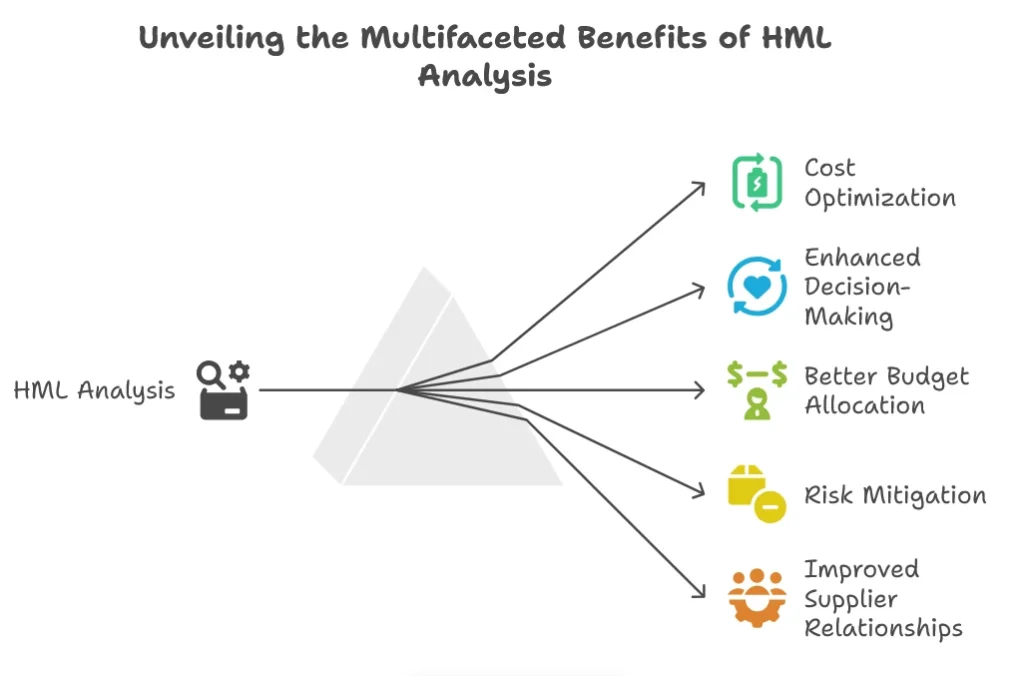

Benefits of HML Analysis in Inventory Management

Different methods of inventory management provide businesses with a systematic approach to classifying stock in real-time. Here are a few benefits of the HML inventory analysis.

1) Cost Optimization

By focusing on high-cost items, businesses can allocate resources more efficiently, reducing waste and overstocking.

2) Enhanced Decision-Making

HML analysis helps prioritise procurement strategies for high-value items, ensuring critical resources are always available.

3) Better Budget Allocation

Categorisation of inventory enables precise budgeting, especially for high-cost items that significantly impact financial planning.

4) Risk Mitigation

High-value items often require additional safeguards. HML analysis helps identify these items and mitigate risks associated with theft or damage.

5) Improved Supplier Relationships

Businesses can negotiate better terms with suppliers of high-value items by emphasising their criticality.

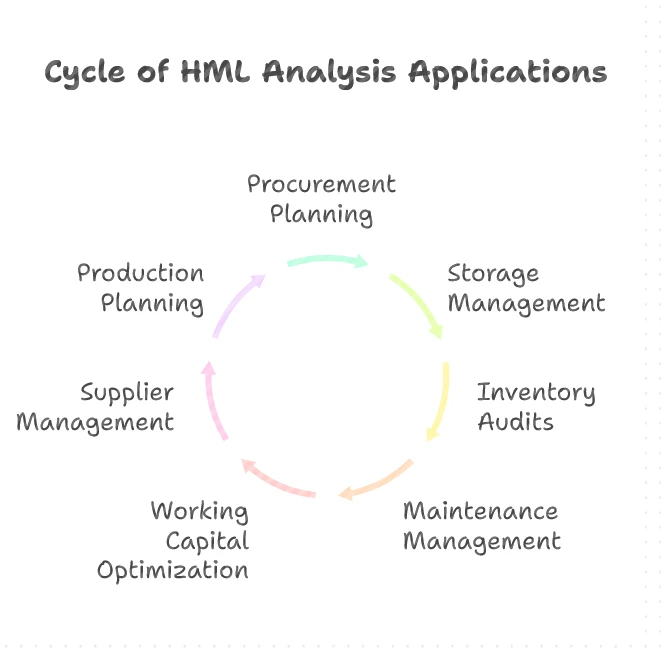

Practical Applications of HML Analysis

HML analysis in inventory management offers diverse applications across industries, helping businesses effectively prioritise and manage their resources. Below are detailed insights into how this analysis is applied:

1. Procurement Planning

HML analysis provides clarity on which inventory items should be procured more carefully. High-cost items, which fall under the “H” category, require rigorous supplier evaluation, negotiation, and prioritisation.

Procurement teams can use this analysis to ensure that these items are sourced from reliable suppliers, even if the lead times are longer. Medium-cost items may have a more flexible procurement process, while low-cost items can be purchased in bulk to benefit from economies of scale.

2. Storage and Security Management

High-value inventory items necessitate stricter storage measures. Businesses can implement advanced inventory optimization processes, such as surveillance cameras, RFID tagging, or biometric access controls, to protect these items. For instance, in a pharmaceutical warehouse, HML analysis helps allocate secure storage for expensive drugs or medical equipment, while less sensitive items can be stored in standard zones.

3. Inventory Audits and Stock Reconciliation

Audits are crucial for maintaining accurate inventory records, especially for high-cost items. With HML analysis, businesses can conduct more frequent and detailed audits for “H” category items, ensuring their presence and condition. This is particularly relevant for industries dealing with luxury goods, electronics, or automotive spare parts, where even minor discrepancies can result in significant losses.

4. Maintenance and Spare Parts Management

In manufacturing, HML analysis aids in managing critical spare parts with high unit prices. These items are often essential for keeping production lines running smoothly. For example, high-value machinery components identified through HML analysis can be stocked as safety inventory to minimise downtime during emergencies. Medium-cost items can be procured on demand, while low-cost items may follow a just-in-time approach.

5. Optimizing Working Capital

HML analysis helps allocate working capital more effectively. High-value items may require larger capital investments upfront, so companies can prioritise their funding and ensure adequate liquidity for procurement. Businesses can use this data to establish optimal reorder points, particularly for high-cost items, to prevent stockouts without overextending their financial resources.

6. Supplier Management and Negotiations

By identifying high-cost items, businesses can negotiate better terms with suppliers, focusing on pricing, quality, and delivery reliability. Building strong relationships with vendors who supply critical high-cost items ensures smoother operations and long-term partnerships. For low-cost items, businesses may choose multiple suppliers to reduce dependency on any single vendor.

7. Production Planning

In manufacturing industries, HML analysis helps prioritize the availability of high-cost raw materials or components. These items are critical for maintaining production schedules and ensuring minimal disruptions.

For example, an automobile manufacturer may use HML analysis to focus on sourcing high-cost components like engines and transmissions, which are integral to the production process, while allocating fewer resources to low-cost nuts and bolts.

Steps to Implement HML Analysis in Inventory Management

Here is a step-by-step guide to implementing the HML analysis technique.

1. Gather Accurate Data

Collect data on all inventory items, focusing on unit prices and quantities.

2. Sort and Categorize

Use software or spreadsheets to sort items by unit price and classify them into H, M, and L categories.

3. Review Regularly

Inventory dynamics change over time. Regular reviews ensure the classification remains relevant.

4. Integrate with Other Analyses

Combine HML analysis with techniques like ABC or XYZ analysis for a comprehensive inventory management approach.

Challenges in HML Analysis

While HML analysis in inventory management is highly beneficial, it comes with challenges:

1. Data Accuracy

Inaccurate pricing data can lead to incorrect categorization, impacting decision-making.

2. Neglect of Consumption Patterns

Since HML focuses solely on unit price, items with high consumption but low unit price may be overlooked.

3. Complexity in Implementation

For large organizations with extensive inventories, implementing HML analysis can be time-consuming without automation.

How HML Analysis Differs from ABC Analysis

Though both HML analysis in inventory control and ABC analysis classify stock, their parameters differ significantly:

| Aspect | HML Analysis | ABC Analysis |

| Classification Type | Unit Price | Consumption Value |

| Primary focus | Cost Management | Inventory Turnover |

| Key Advantage | Simplifies high-cost item | Improves inventory control |

Tips for Maximizing the Impact of HML Analysis

Predicting the annual product demand is difficult but it’s possible to maximise the benefits of your stock process. Here’s how you can achieve precision and efficiency.

1. Automate the Process

Use inventory management software to handle large datasets and perform classifications efficiently.

2. Combine with ERP Systems

Integrate HML analysis into ERP systems for real-time insights and actionable strategies.

3. Train Your Team

Educate your staff on the importance of HML analysis and how to use its insights effectively.

4. Use Visual Dashboards

Represent HML data through dashboards for better interpretation and quicker decision-making.

Conclusion

HML analysis in inventory management identifies seasonal sales patterns. You can focus more on high-value items that generate more revenue and push the low-demand products at the bottom. For more actionable tips to boost inventory efficiency, contact Qodenext today.

FAQs – HML Analysis in Inventory Management

1. What industries benefit most from HML analysis in inventory management?

Industries with high-cost items, such as manufacturing, healthcare, and electronics, benefit the most. It helps prioritize resources and manage costs efficiently.

2. Can HML analysis be used with other inventory management techniques?

Yes, combining HML with ABC or XYZ analysis provides a holistic view of inventory management.

3. How to optimise inventory levels?

It depends on the industry and inventory turnover. Quarterly or bi-annual reviews are common practices.

4. What tools can simplify HML analysis in inventory management?

Inventory management software like SAP, Oracle, or Zoho Inventory can automate the process, making it more accurate and efficient.

5. Does HML analysis consider seasonal variations?

No, HML analysis focuses on unit price. To account for seasonality, integrate it with other analytical methods.

6. What is HML analysis in inventory management?

HML analysis in inventory management is a method of classifying inventory into High, Medium, and Low categories based on unit price.

7. What is the full form of HML analysis?

The full form of HML analysis is High, Medium, and Low.

8. How does HML analysis differ from ABC analysis?

HML analysis focuses on unit price, while ABC analysis focuses on annual consumption value.

9. What are the main benefits of HML analysis in inventory management?

It optimizes costs, improves procurement planning, enhances supplier relationships, and reduces risks for high-value items.

10. Which industries use HML analysis the most?

Manufacturing, pharmaceuticals, healthcare, automotive, and electronics industries rely heavily on HML analysis for managing expensive items.