Warehouses are no longer just large storage spaces—they’re becoming intelligent, connected ecosystems. Welcome to the era of digital warehousing, where real-time data, automation, and smart technology converge to streamline operations and boost productivity. It’s not about stocking goods, it’s all about how efficiently you manage your inventory.

If you’re a supply chain manager, warehouse operator, or logistics head trying to wrap your head around digital warehouses, this step-by-step guide will walk you through everything you need to know—from the basics to the benefits and how to get started.

What Is Digital Warehousing?

Digital warehouse refers to the integration of technology into traditional warehouse operations to improve visibility, efficiency, accuracy, and scalability. It replaces manual processes with digital tools such as:

- Warehouse Management Systems (WMS)

- Internet of Things (IoT)

- Artificial Intelligence (AI)

- Barcode & RFID tracking

- Robotics and automation

With these technologies, a digital warehouse setup enables real-time inventory tracking, automated workflows, predictive maintenance, and seamless data sharing across the supply chain.

Why Digital Warehousing Matters in 2024

The rise of eCommerce, omnichannel fulfilment, and consumer demand for faster deliveries has exposed the limits of manual or semi-automated warehouses. Businesses are shifting toward digital warehousing to:

- Improve order accuracy and reduce fulfilment errors

- Gain real-time visibility of inventory across locations

- Optimize space utilization and layout

- Lower labor dependency and operational costs

- Scale operations to meet demand surges

- Implement different types of warehouse automation for faster results.

In a competitive environment where every second counts, a digital warehouse becomes a critical differentiator.

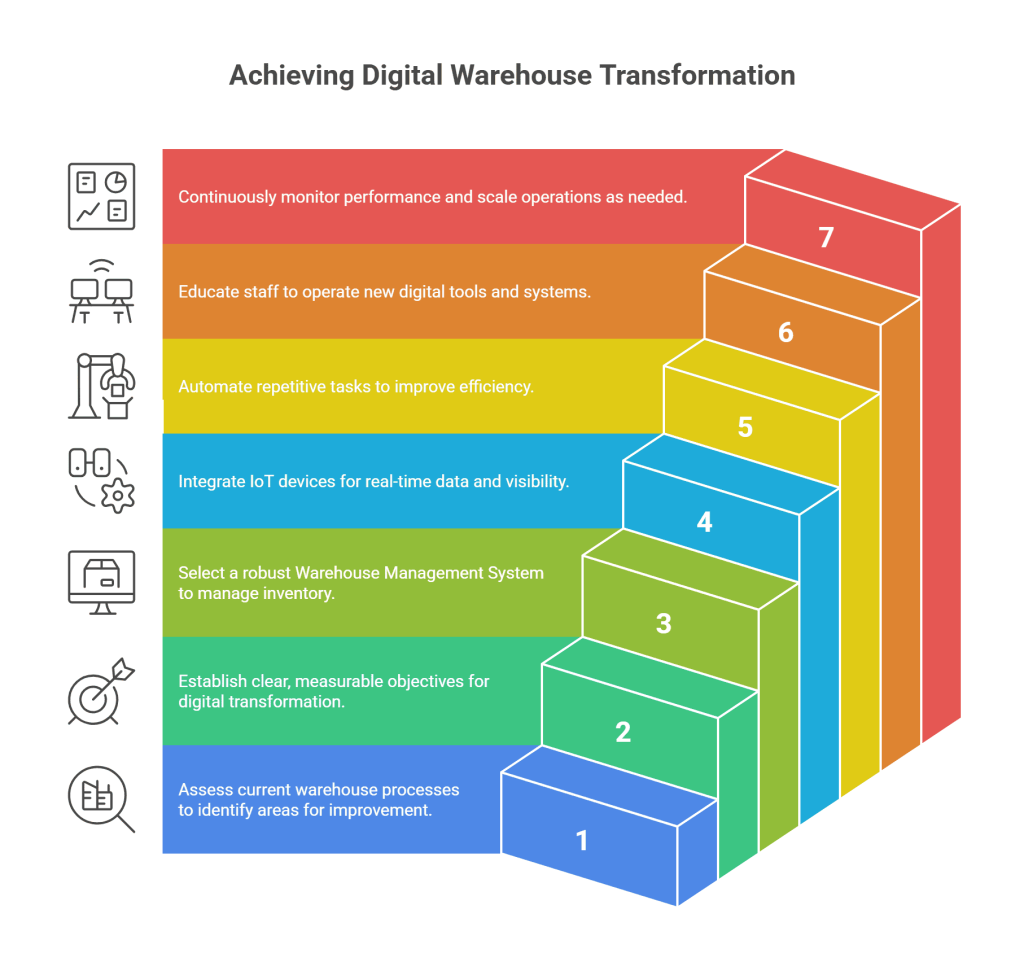

Step-by-Step Guide to Adopting a Paperless Warehouse

Step 1: Audit Your Current Warehouse Operations

Before going digital, assess the current state of your warehouse. Identify:

- Manual processes that are slow or error-prone

- Inventory inaccuracies or misplacements

- Bottlenecks in picking, packing, or shipping

- Integration gaps between ERP, WMS, or transport systems

This audit will uncover the key areas where digital warehousing can offer the most value.

Step 2: Define Your Warehousing Goals

What are you trying to achieve? Common goals include:

- Real-time inventory tracking

- Automated inbound/outbound processes

- Labor optimization

- Enhanced order cycle time

Having clear, measurable goals will help you choose the right digital warehousing technologies for your operations.

Step 3: Choose a Robust Warehouse Management System (WMS)

WMS is a crucial part of automated inventory protocols. This system:

- Tracks inventory movements in real time

- Optimizes picking paths and storage locations

- Generates actionable analytics and reports

- Integrates with ERP, TMS, CRM, and eCommerce platforms

- Look for cloud-based, scalable WMS platforms that support APIs and mobile devices.

Step 4: Implement IoT and Sensor-Based Tracking

IoT devices like RFID tags, barcode scanners, and geo sensors provide instant visibility into:

- Stock levels

- Product location

- Ambient conditions (for perishable goods)

These IoT devices feed real-time data into your WMS, creating a transparent, responsive digital warehouse environment.

Step 5: Automate Core Processes

Start small—automate repetitive tasks like:

- Barcode scanning

- Pick-to-light or voice picking

- Conveyor belt sorting

- Label printing

As your team gets comfortable, consider investing in robotics for high-volume zones. The beauty of a digital warehouse is that you can scale automation at your own pace.

Step 6: Train Your Workforce

No digital warehouse strategy succeeds without people. Train your staff to:

- Operate handheld scanners and IoT devices

- Understand digital dashboards

- Troubleshoot basic software/hardware issues

- Follow new workflows driven by automation

- A digitally literate workforce is essential for long-term ROI.

Step 7: Monitor, Optimize, and Scale

Use your WMS dashboard and analytics to monitor:

- Order accuracy

- Inventory turnover

- Labor efficiency

- Space utilization

With this data, tweak processes regularly. Digital warehousing allows you to test, adapt, and scale your operations with agility.

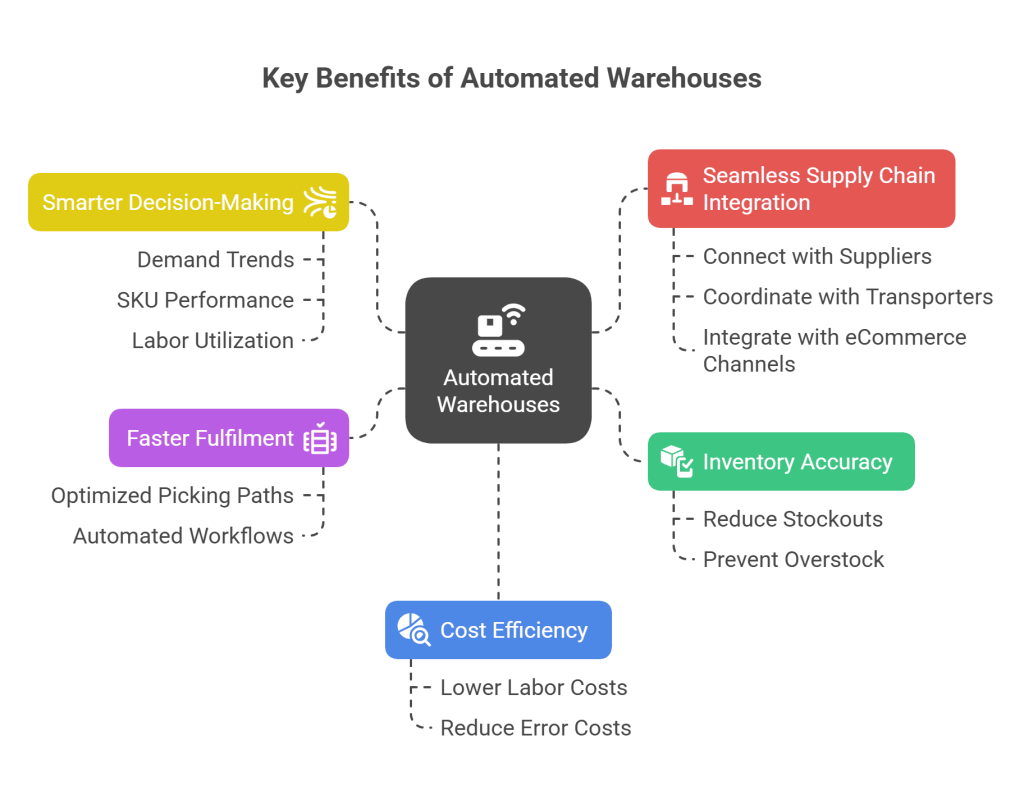

Key Benefits of Automated Warehouses

Implementing warehouse management systems delivers a range of tangible and strategic benefits:

1. Inventory Accuracy

Track every product’s movement in real time, reducing stockouts and overstock situations.

2. Faster Fulfilment

Optimized picking paths and automated workflows reduce order-to-dispatch time significantly.

3. Smarter Decision-Making

AI-powered analytics give actionable insights on demand trends, SKU performance, and labor utilization.

4. Cost Efficiency

While initial investments are required, digital warehouses lower long-term labor and error costs.

5. Seamless Supply Chain Integration

Digital systems connect easily with suppliers, transporters, and eCommerce channels for real-time coordination.

Digital Warehouse in Action: Real-World Example

A mid-sized retail distribution center in India adopted a digital warehouse by implementing RFID-based tracking, a WMS, and pick-to-light systems.

Within 6 months, they saw:

- 30% improvement in order accuracy

- 25% reduction in picking time

- 18% savings in labor costs

By integrating their WMS with transport partners, they also reduced last-mile delivery delays.

Common Challenges and How to Overcome Them

| Challenges | Solutions |

| Resistance to change | Involve workers early, explain benefits, and offer proper training. |

| High investment costs | Start with a modular warehousing approach. |

| Integration issues | Choose warehouse automation software with good API support and vendor integration. |

| Data overload | Focus on KPIs |

Future of Digital Warehouses

Looking ahead, digital warehouses will get smarter and more predictive, driven by:

- AI and machine learning for predictive analytics

- Autonomous mobile robots (AMRs)

- Drones for inventory audits

- Blockchain for tamper-proof inventory records

Digital-first warehouses will become the new norm as these technologies mature across industries.

FAQs – Digital Warehousing

1. Is digital warehousing only for large companies?

No. Businesses of all sizes can benefit. Even small warehouses can start with barcode systems and a cloud WMS.

2. What is the difference between a traditional and digital warehouse?

A traditional warehouse relies on manual logs and basic software. A digital warehouse uses integrated systems, real-time tracking, and automation to manage operations efficiently.

3. How long does it take to implement a digital inventory system?

Depending on scale, it can take 3 to 12 months. A modular approach allows you to implement in phases without major disruption.

4. Can digital warehouses reduce labor costs?

Yes. Automation, better planning, and error reduction contribute to 15–30% lower labor costs in most cases.

5. Is data security a concern in digital warehouses?

Cloud-based WMS platforms are typically secure and compliant. Always choose vendors with strong encryption, regular backups, and support protocols.

Conclusion

Digital warehousing is not just a trend; it’s the foundation of modern logistics. With the right tools, a clear roadmap, and trained staff, even traditional warehouses can evolve into smart, scalable, and resilient fulfilment hubs.

By embracing digital inventory, you future-proof your business, enhance customer satisfaction, and unlock new levels of efficiency. The journey starts with one small step: digitize your inventory, automate your process, and let data lead the way. Ready to automate your supply traceability? Start with Qodenext today.