In the global supply chain landscape, businesses must ensure stock availability while minimising excess inventory. This is where automated replenishment plays a crucial role. By leveraging technology to monitor stock levels and trigger restocking processes, businesses can improve efficiency, reduce waste, and maintain a seamless flow of goods.

In this guide, we’ll explore AI-driven replenishment, how it works, its benefits, challenges, and best practices for modern supply chains.

What is Automated Replenishment?

Automated replenishment is a technology-driven approach that uses software, artificial intelligence (AI), and real-time data to manage inventory levels and automatically reorder products when stock reaches a predefined threshold.

Unlike manual replenishment, where businesses rely on human intervention to monitor stock and place orders, automated replenishment ensures continuous availability by analyzing demand patterns, sales trends, and supply chain factors.

How Does Automated Replenishment Work?

The process of automated replenishment typically follows these steps:

1️) Stock Monitoring: AI-driven systems track real-time inventory levels.

2️) Demand Forecasting: Algorithms analyse historical sales data, seasonality, and market trends to predict future demand.

3) Replenishment Trigger: When stock reaches a pre-set reorder point, the system automatically generates a purchase order.

4️) Supplier Communication: Orders are placed with suppliers or warehouses, ensuring timely replenishment.

5) Stock Updates: Inventory levels are updated once replenished, and the system continues monitoring.

This seamless auto-replenishment cycle eliminates stockouts and overstocking, improving overall supply chain efficiency.

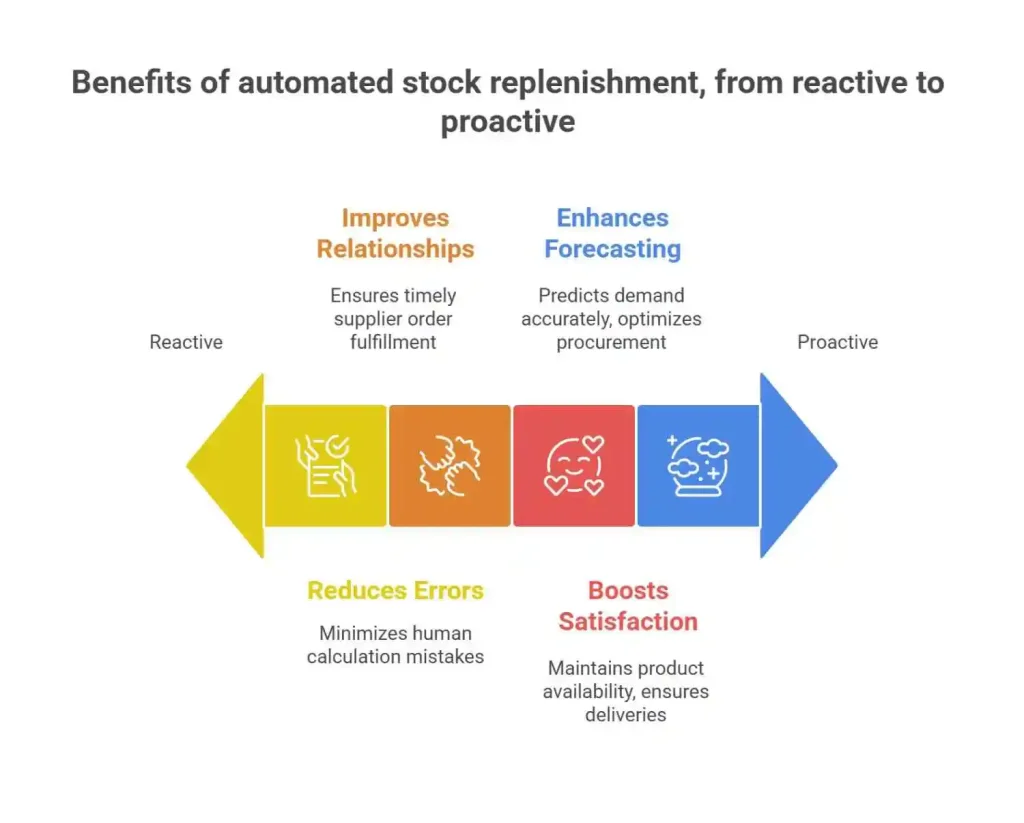

Key Benefits of Automated Stock Replenishment

Implementing automated replenishment provides several advantages:

1. Eliminates Stockouts & Overstocking

One of the biggest challenges in inventory management is balancing stock availability with demand. Automated EPM and BI-based inventory planning ensures that businesses:

- Always have the right amount of inventory.

- Avoid inadequate inventory during peak seasons.

- Reduce excess inventory, minimizing storage costs and waste.

2. Reduces Human Error & Labor Costs

Manual stock tracking and order placement are prone to errors and inefficiencies. By automating the process, businesses:

- Minimize errors in inventory calculations.

- Reduce labor costs associated with manual monitoring.

- Free up employees to focus on strategic tasks rather than routine ordering.

3. Enhances Demand Forecasting Accuracy

AI-powered automated replenishment systems analyze historical sales, seasonal trends, and customer behavior to predict demand more accurately. This helps businesses:

- Optimise procurement schedules.

- Adjust stock levels based on real-time demand fluctuations.

- Avoid sudden shortages during peak seasons.

4. Improves Supplier Relationships

Consistent, automated ordering improves coordination with suppliers, ensuring:

- Timely order fulfillment.

- Reduced delays and backorders.

- Better negotiation leverage due to consistent purchase volumes.

5. Boosts Customer Satisfaction

Customers expect fast, reliable service. Self-regulated replenishment helps businesses:

- Maintain product availability across all locations.

- Ensure on-time deliveries.

- Enhance brand loyalty by providing a seamless shopping experience.

6. Increases Profit Margins

Optimized E-commerce inventory management leads to cost savings in multiple areas, including:

- Lower storage and warehousing costs.

- Reduced waste from expired or obsolete products.

- Higher sales due to continuous product availability.

Challenges of Implementing Automated Replenishment

Despite its advantages, automated stock replenishment comes with certain challenges:

1. Initial Setup Costs

Investing in AI-driven inventory management software and integrating it with existing systems can be expensive. However, the long-term savings outweigh the initial investment.

2. Data Accuracy Dependence

The effectiveness of automated inventory replenishment relies on accurate data. Poor data quality can lead to incorrect forecasts, resulting in overordering or understocking.

3. Supplier Reliability Issues

If suppliers fail to fulfill automated orders on time, businesses can still experience stock shortages. Establishing reliable supplier networks is essential.

4. Customization Complexity

Different businesses have unique replenishment needs. Some systems may require customisation to align with specific workflows, which can be time-consuming.

Best Practices for Successful Automated Replenishment

To maximise the benefits of automated replenishment, businesses should follow these best practices:

1. Invest in AI & Cloud-Based Inventory Systems

Modern AI-powered inventory management tools provide real-time insights and automated decision-making. Cloud-based systems ensure scalability and remote access.

2. Define Accurate Reorder Points

Setting appropriate minimum and maximum stock levels helps optimize replenishment cycles and prevents excessive ordering.

3. Integrate with Supplier Networks

Establishing seamless digital communication with suppliers ensures smooth order fulfillment and reduces delays.

4. Regularly Audit Inventory Data

Automated supply replenishment systems rely on accurate data. Conducting periodic inventory audits helps identify discrepancies and system errors.

5. Use Predictive Analytics for Better Forecasting

Leveraging machine learning algorithms helps businesses forecast demand trends more accurately, reducing the risk of stockouts and overstocking.

6. Monitor & Optimize Performance

Regularly reviewing automated stock refilling metrics allows businesses to fine-tune inventory strategies for continuous improvement.

Industries That Benefit from Automated Stock Replenishment

Major industries rely on consistent replenishment to meet rising customer expectations. Here are the industry types listed below.

1. Retail & eCommerce

Retailers use automated stock management to maintain product availability, ensuring customers always find their favourite products.

2. Manufacturing

Factories rely on an automatic replenishment system to avoid raw material shortages and streamline production.

3. Healthcare & Pharmaceuticals

Hospitals and pharmacies use automated stock monitoring to maintain essential medical supplies and medications.

4. Food & Beverage

Grocery stores and restaurants use automated stock renewal to manage perishable goods efficiently, reducing food waste.

5. Automotive Industry

Auto manufacturers and spare parts suppliers use automated stock tracking to avoid production delays.

Conclusion

Automated replenishment is revolutionising inventory management across industries. By leveraging AI, real-time data, and predictive analytics, businesses can optimise stock levels, reduce costs, and enhance customer satisfaction. While implementation challenges exist, following best practices and investing in reliable systems ensures a smooth and efficient replenishment process.

Do you want to optimise your traceability systems? Contact Qodenext today.

FAQs – Automated Replenishment

1. What is the main purpose of automated stock management?

The primary goal of automated refilling is to ensure that businesses always have the right amount of inventory by automatically restocking items when stock levels reach a predefined threshold.

2. How does AI-driven replenishment differ from manual replenishment?

Unlike manual replenishment, which requires human monitoring and ordering, automated renewal uses AI and real-time data to predict demand and place orders automatically.

3. What types of businesses benefit from automated stock renewal?

Retailers, manufacturers, healthcare providers, food suppliers, and logistics companies benefit from automated restocking by optimising stock levels and reducing operational inefficiencies.

4. Can small businesses implement automated restocking?

Yes, many cloud-based inventory management solutions offer scalable automated restocking features tailored for small businesses.

5. What are the risks of stock replenishment?

Potential risks include data inaccuracies, supplier delays, and software integration challenges. However, these can be mitigated through regular audits, reliable supplier partnerships, and system optimization.

6. How can businesses choose the right automated restocking system?

Businesses should look for AI-driven analytics, cloud integration, real-time tracking, and customization capabilities when selecting an automated stock renewal solution.

7. What types of automated replenishment strategies exist?

There are several strategies businesses can adopt, including minimum/maximum replenishment (setting lower and upper stock limits), forecast-based replenishment (using sales history to predict demand), vendor-managed inventory (where the supplier handles restocking), just-in-time replenishment (ordering only when needed), and automatic top-off for high-turnover items. Each strategy suits different business needs and product types.

8. How do businesses ensure automated replenishment adapts to demand fluctuations?

Modern systems use AI and machine learning algorithms to analyze real-time and historical sales data, seasonal trends, and even external events. By continuously updating forecasts, these systems adjust reorder points dynamically, helping businesses respond swiftly to sudden changes in demand or unexpected spikes.

9. What are the risks of relying solely on automated recommendations?

Automated replenishment suggestions may not always align perfectly with sudden market shifts or unique customer behaviors. If systems depend too heavily on historical data or rigid rules, they might not react quickly enough to rapid changes, leading to overstocking or stockouts. Human oversight remains essential to review exceptions and override automated decisions when necessary.

10. How do companies manage data integration for automated replenishment?

Effective automated replenishment depends on seamless integration between inventory management, sales, and supplier systems. Many businesses use cloud-based platforms and robust APIs to connect different software tools, ensuring real-time data accuracy and cutting down on manual data entry errors.