The smart warehouse is no longer a futuristic concept – it’s a present-day reality. And at the heart of it lies one core enabler: sensors.

The Internet of Things (IoT) is transforming warehouses by embedding intelligence into every corner, from shelves to shipping docks. But what makes this transformation possible? The answer lies in the types of IoT sensors deployed across the warehouse floor.

From tracking temperature-sensitive goods to monitoring real-time movement of inventory, sensors are the silent heroes making warehouse management faster, safer, and smarter.

In this blog, we break down the different types of sensors in IoT, how they work, and why they’re essential to the modern supply chain.

What Are IoT Sensors and Why Do They Matter in Warehousing?

Before we get into the classification of sensors in IoT, let’s understand the basics. IoT sensors are devices that collect specific types of data from their surroundings and transmit it over a network.

In a warehouse, this could mean detecting movement, temperature, humidity, light, gas, or even vibration.

Their value? They bring real-time visibility, automate manual tasks, and enable predictive insights – which translates to better decision-making and reduced errors. With the right sensor applications in industry, warehouses can operate leaner and smarter.

Now that we know what sensors are and why they matter, let’s explore the key types used in warehouse management.

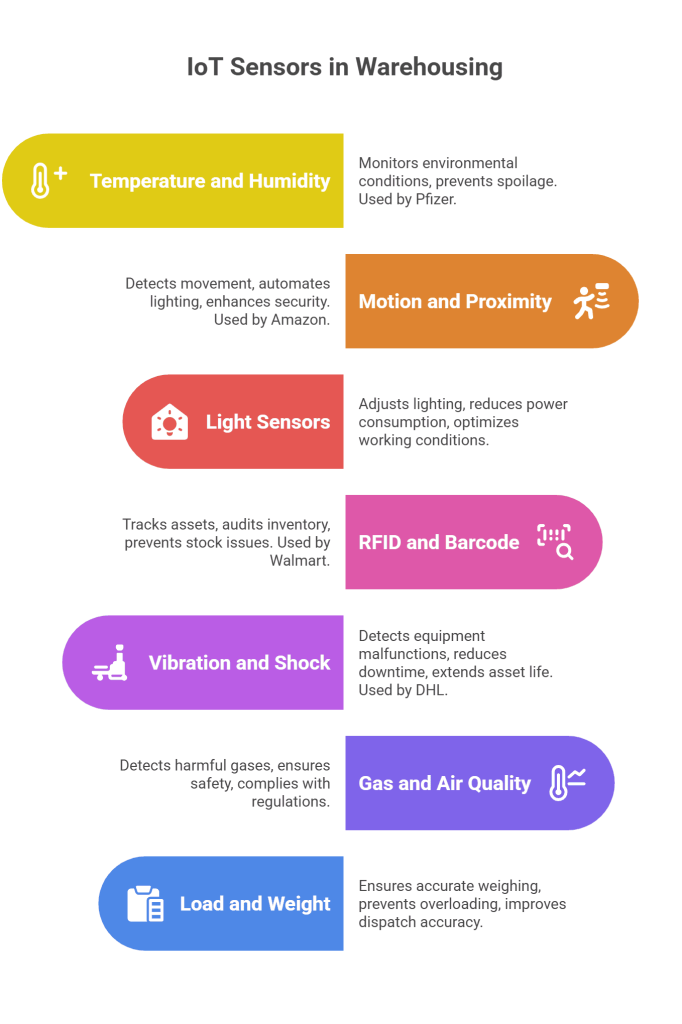

1. Temperature and Humidity Sensors

Especially important for warehouses storing pharmaceuticals, fresh produce, or chemicals, these sensors monitor environmental conditions in real time. Any deviation from the set range triggers alerts, helping prevent spoilage or product damage.

Pfizer, for instance, uses temperature sensors across its cold chain to ensure vaccine integrity during storage and transport.

These are among the most widely adopted industrial IoT sensors, making them crucial for sensitive inventory.

Now that we’ve seen how temperature and humidity sensors work, let’s look at sensors that track movement.

2. Motion and Proximity Sensors

Used to detect the presence or movement of people or objects, these sensors are essential for automating lighting, triggering security protocols, or monitoring product movement.

Amazon’s fulfillment centers use a variety of motion sensors to control automated guided vehicles (AGVs) and optimize picker routes in real time. These are classic examples of sensors used in IoT to enhance efficiency and safety.

Next, let’s explore how light sensors support warehouse energy efficiency.

3. Light Sensors

Light sensors detect the level of ambient light and adjust lighting systems accordingly. By automating brightness based on natural light availability, warehouses reduce power consumption and maintain optimal working conditions.

Some advanced facilities integrate these with motion sensors so lights only turn on in occupied zones – a popular strategy among companies aiming to go green.

Having explored lighting automation, let’s now look at how RFID sensors revolutionize inventory tracking.

4. RFID and Barcode Sensors

These aren’t traditional sensors in the physical sense, but they function as data collectors in IoT systems. RFID tags and barcode readers are pivotal for real-time asset tracking, inventory audits, and preventing stock-outs or overstocking.

Walmart is a long-time adopter of RFID to streamline supply chain processes. Their use of RFID-enabled packaging improved shelf availability by over 16%, according to industry reports.

Now that we’ve tackled RFID and tracking sensors, let’s move to those ensuring structural safety.

5. Vibration and Shock Sensors

These sensor types in IoT are ideal for detecting equipment malfunctions or damage during transit. Installed on conveyor belts, forklifts, or pallets, they help reduce downtime and extend asset life.

Logistics companies like DHL use vibration sensors to monitor high-value or fragile shipments, ensuring nothing gets damaged in transit.

Next up: sensors that help you manage air quality and safety.

6. Gas and Air Quality Sensors

These are used to detect harmful gases, humidity levels, or particulate matter. They’re especially useful in warehouses that store flammable or hazardous materials.

By integrating gas sensors with alert systems, companies reduce workplace hazards and ensure compliance with safety regulations. These are often part of larger IoT sensor applications in safety monitoring systems.

With air quality sensors covered, let’s now understand how weight and load sensors help in material handling.

7. Load and Weight Sensors

Installed on pallet scales or material handling equipment, these sensors ensure that goods are weighed accurately and equipment isn’t overloaded. This not only prevents accidents but also improves dispatch accuracy.

Many e-commerce warehouses integrate weight sensors to automatically verify packed shipments before they leave the warehouse.

Now that we’ve looked at physical measurement sensors, let’s briefly touch upon their classifications.

Classification of Sensors in IoT

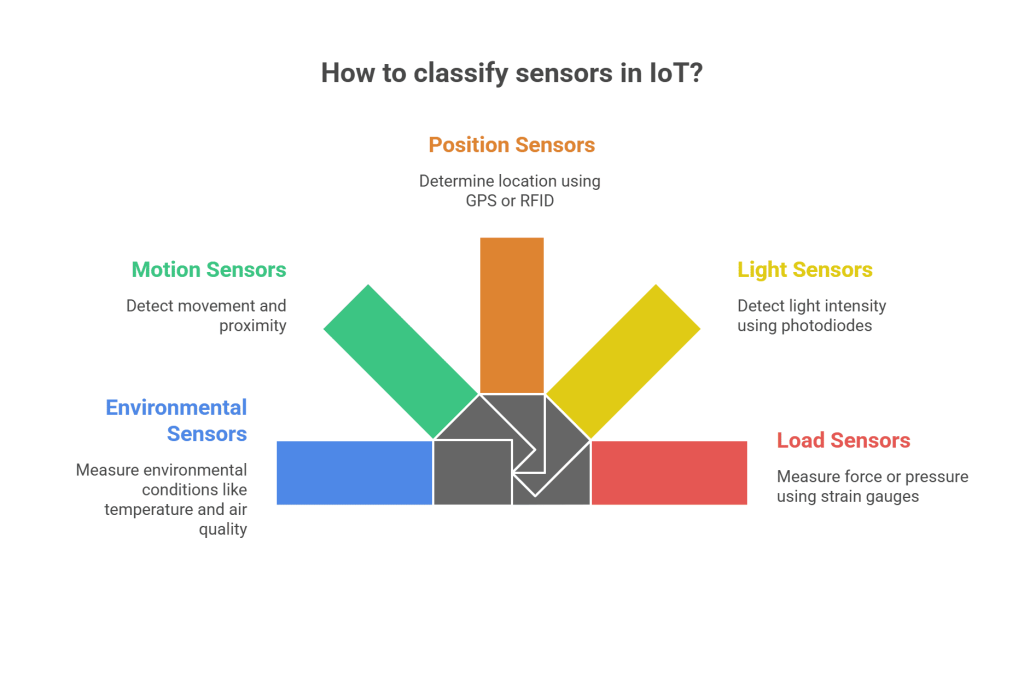

The classification of sensors in IoT is generally based on what they measure and how they function. Here are a few key classifications:

- Environmental Sensors: Temperature, humidity, gas, air quality

- Motion Sensors: Proximity, motion detectors, vibration sensors

- Position Sensors: RFID, GPS, barcode

- Light Sensors: Photodiodes, LDRs

- Load Sensors: Strain gauges, pressure sensors

This classification helps in selecting the right tools for your warehouse needs.

Now that we understand sensor types and categories, let’s explore some tech trends shaping their use.

Trends in Industrial IoT Sensors

Modern warehouses are now combining industrial IoT sensors with AI and machine learning to unlock predictive analytics. For example:

- Predictive maintenance using vibration and temperature data

- Automated restocking via real-time weight sensors

- Heat maps for warehouse traffic optimization using motion sensors

Bosch and Siemens have implemented sensor-driven analytics across their logistics arms, cutting operational inefficiencies and downtime.

With trends explored, let’s now understand how to choose the right sensor mix.

Selecting the Right Sensors for Your Warehouse

Choosing among the types of sensors in IoT depends on factors like:

- The nature of goods stored

- Temperature/humidity sensitivity

- Security and safety requirements

- Real-time visibility needs

- Integration with existing WMS or ERP

Cloud-enabled systems make it easier to scale and update sensor networks without huge infrastructure changes.

FAQs: 7 Smart Sensors Driving the Future of Warehouse Management

1. Are IoT sensors hard to integrate with legacy warehouse systems?

Not necessarily. Many cloud-based MES and WMS platforms now support plug-and-play integrations with popular sensor types.

2. How do sensors support warehouse sustainability goals?

They reduce energy usage through smart lighting, optimize space utilization, and improve transport planning to reduce carbon emissions.

3. Are all sensors wireless?

No, while most IoT sensors today are wireless for flexibility, some critical sensors still require wired connections for power and data reliability.

4. Do warehouses need to calibrate sensors regularly?

Yes, especially sensors measuring critical variables like weight or temperature, to ensure accuracy and avoid compliance issues.

5. Can sensors detect theft or unauthorized access?

Yes. Motion and proximity sensors can alert teams to unusual activity, especially after hours, enhancing warehouse security.

Conclusion

In 2025 and beyond, warehouses that fail to adopt sensor technology risk falling behind. The different types of sensors in IoT play a foundational role in improving safety, visibility, and operational speed.

From RFID to temperature sensors, every tool adds intelligence to warehouse operations.

Knowing how to integrate the right mix of sensors used in IoT could be your key to unlocking the next level of productivity.