The logistics industry is undergoing a massive transformation driven by artificial intelligence. As warehouses become smarter, faster, and more data-driven, the implementation of AI in logistics is no longer a futuristic concept—it’s a present-day necessity. From optimizing storage to managing supply chains, AI-powered systems are drastically improving operational efficiency, accuracy, and scalability.

In this blog, we’ll explore five key logistics systems that are revolutionizing warehouse operations and shaping the future of supply chain management.

5 AI in Logistics Systems that Are Revolutionizing Warehouses

The Rise of Logistics Automation

The logistics industry has long been the backbone of global trade and commerce. Whether it’s moving raw materials to factories or delivering finished products to customers, logistics ensures that goods reach the right place at the right time. But with growing consumer expectations, shrinking delivery windows, and increasingly complex supply chains, traditional logistics processes are no longer enough. The solution? Logistics automation is a game-changer that is reshaping warehouse operations from the ground up.

Logistics automation refers to the use of technology to perform logistics tasks with minimal human intervention. These tasks can range from inventory tracking and order picking to shipment scheduling and delivery route planning. By replacing manual processes with digital and mechanical systems, businesses gain faster turnaround times, improved accuracy, and significantly reduced operational costs.

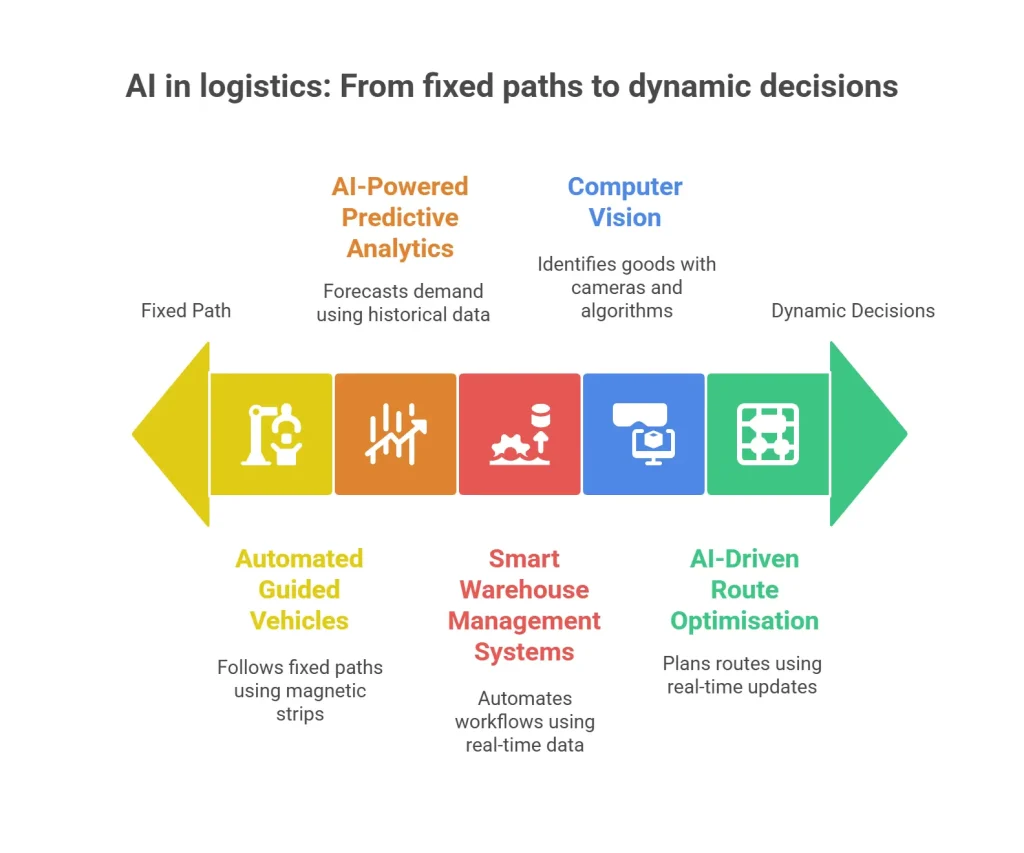

5 AI in Logistics Systems – Detailed Breakdown

1. Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs)

One of the most significant advancements in AI in logistics is the integration of AGVs and AMRs into warehouse environments. These AI-powered machines are designed to handle repetitive, labor-intensive tasks such as transporting goods from one point to another.

How They Work:

AGVs typically follow fixed paths using magnetic strips or wires, while AMRs use sensors, maps, and machine learning algorithms to navigate dynamically. Powered by AI and machine vision, these robots identify obstacles, recalculate routes, and avoid collisions in real time.

Benefits:

- Increased efficiency in material handling

- Reduced human error and workplace injuries

- Optimized labor utilization

- 24/7 operation, resulting in faster turnaround times

Many warehouse giants like Amazon and Alibaba have already deployed fleets of AMRs in their fulfilment centers, highlighting the growing reliance on AI in logistics.

2. AI-Powered Predictive Analytics

Forecasting is crucial in warehouse management, and AI has taken predictive analytics to the next level. With the ability to analyze vast volumes of historical and real-time data, AI algorithms forecast inventory demands, supply chain disruptions, and even maintenance schedules. Modern tools use a combination of predictive vs prescriptive to analyze patterns.

How It Works:

AI systems extract patterns from sales data, weather forecasts, consumer trends, and economic indicators to make data-driven predictions. These insights allow logistics managers to stock inventory more accurately, avoid overstocking or understocking, and streamline resource allocation.

Benefits:

- Improved demand forecasting

- Cost savings through optimized inventory

- Reduced stockouts and overstock situations

- Minimized waste in perishables

This application of AI in logistics enables companies to stay one step ahead of market demand and ensure seamless delivery operations.

3. Smart Warehouse Management Systems (WMS)

Warehouse Management Systems powered by AI are taking traditional WMS platforms to a new level of intelligence. These systems leverage real-time data, machine learning, and natural language processing to automate complex workflows and make intelligent decisions on the fly.

Features:

- Dynamic slotting: AI determines the most efficient location for each item in the warehouse.

- Intelligent order picking: Suggests the optimal picking route for workers or robots.

- Voice-enabled commands: Workers interact with the system hands-free using natural language.

- Real-time monitoring: Detects bottlenecks and provides actionable insights.

By using AI in logistics to enhance WMS, warehouses can experience greater control, traceability, and accuracy in daily operations.

4. Computer Vision for Quality Control and Inventory Management

Computer vision—a subset of AI—is transforming how warehouses manage inventory and quality assurance. Equipped with cameras and AI algorithms, computer vision systems can identify, count, and inspect goods with incredible precision.

Use Cases:

- Automated inventory scanning using drones or fixed cameras

- Real-time damage detection during receiving and dispatch

- Barcode and label reading even under poor lighting or torn packaging

- Shelf monitoring for restocking alerts

This system significantly reduces manual errors and enhances warehouse visibility. When integrated into other logistics platforms, computer vision ensures an interconnected, intelligent warehouse ecosystem.

5. AI-Driven Route Optimization and Fleet Management

While not confined solely within warehouse walls, AI in logistics also extends to fleet operations that interface directly with warehouse dispatch teams. AI systems now play a vital role in route planning, delivery scheduling, and vehicle maintenance.

Functionalities:

- AI-based routing algorithms reduce delivery times and fuel usage

- Real-time traffic and weather updates adjust routes dynamically

- Predictive maintenance identifies potential vehicle issues before breakdowns

- Telematics integration ensures visibility of every vehicle

As warehouses grow increasingly integrated with last-mile delivery, route optimization powered by AI ensures that goods are dispatched with speed and precision.

The Bigger Picture: AI-Integrated Warehouse Ecosystems

When these five AI systems work in synergy, the result is a truly smart warehouse—one that operates autonomously, responds dynamically to changes, and learns continuously to improve its operations.

From the loading dock to the delivery truck, the application of AI in logistics is driving warehouses toward a more sustainable, scalable, and resilient future. As AI capabilities continue to evolve, we can expect even deeper integration of smart technologies across every facet of the logistics chain.

FAQs – AI in Logistics

1. What is AI in logistics?

AI in warehousing refers to the application of artificial intelligence technologies—such as machine learning, computer vision, and predictive analytics—to automate, optimize, and enhance various logistics and supply chain processes, particularly in warehouses.

2. How does AI improve warehouse operations?

AI enhances warehouse operations by improving inventory accuracy, streamlining order fulfilment, reducing errors, and boosting labor productivity. It helps automate repetitive tasks and enables data-driven decision-making.

3. Is logistics automation only beneficial for large companies?

No. While large companies were early adopters, AI technologies are becoming more accessible and scalable, making it feasible for small and medium-sized enterprises to benefit from AI as well.

4. Are there risks in using AI in warehouses?

Like any technology, AI comes with risks such as data privacy concerns, integration challenges, and initial investment costs. However, with the right infrastructure and implementation strategy, these risks can be mitigated effectively.

5. Will AI replace human workers in logistics?

AI is more likely to augment human capabilities rather than replace them. It allows workers to focus on complex, value-added tasks while machines handle repetitive and physically demanding work.

6. What is the ROI of implementing AI?

Companies implementing AI often report increased efficiency, lower operational costs, faster delivery times, and improved customer satisfaction, resulting in a strong return on investment (ROI) over time.

Conclusion

Warehouses are no longer just storage spaces—they are becoming intelligent nerve centers of the supply chain. With the help of AGVs, predictive analytics, AI-powered WMS, computer vision, and intelligent routing, the role of AI in logistics is becoming indispensable.

For logistics businesses aiming to stay competitive, investing in these AI-driven solutions is not optional; it’s essential. Contact Qodenext today to automate traceability and supply chain visibility.