In the fast-paced world of supply chain management, organizations are constantly seeking ways to streamline operations, minimize costs, and maximize productivity. One such approach that has revolutionized inventory management is Just-in-Time (JIT) inventory management. JIT is a strategy that aims to synchronize production and distribution processes with customer demand, eliminating excessive inventory and reducing wastage.

By maintaining lean inventories and relying on efficient communication and coordination, businesses can effectively meet customer needs while minimizing storage costs and minimizing the risk of obsolete stock. In this blog, we will delve into the intricacies of JIT inventory management, exploring its benefits, challenges, and key considerations for successful implementation.

What Is Jit Inventory Management?

Just-in-Time (JIT) inventory management is a supply chain strategy that focuses on minimizing inventory levels by receiving and producing goods and materials only when needed. It aims to optimize efficiency and reduce waste by synchronizing production with customer demand.

JIT inventory management relies on timely and accurate communication between suppliers, manufacturers, and retailers to ensure that products are delivered and produced just in time to meet customer orders. By implementing JIT, businesses can achieve several key benefits, including:

1. Reduced carrying costs:

JIT minimizes the need for excess inventory, thereby lowering storage costs and the risk of obsolescence.

2. Improved cash flow:

With reduced inventory levels, capital is freed up and can be utilized for other operational needs.

3. Enhanced quality control:

JIT emphasizes quality control measures throughout the production process, leading to improved product quality and customer satisfaction.

4. Increased productivity:

By eliminating waste and streamlining processes, JIT boosts overall productivity and operational efficiency.

5. Efficient supply chain coordination:

JIT relies on effective communication and collaboration among suppliers, manufacturers, and retailers to ensure a smooth flow of materials and goods.

Overall, JIT inventory management is a dynamic approach that enables organizations to operate with lean inventories while maintaining high levels of customer satisfaction and profitability.

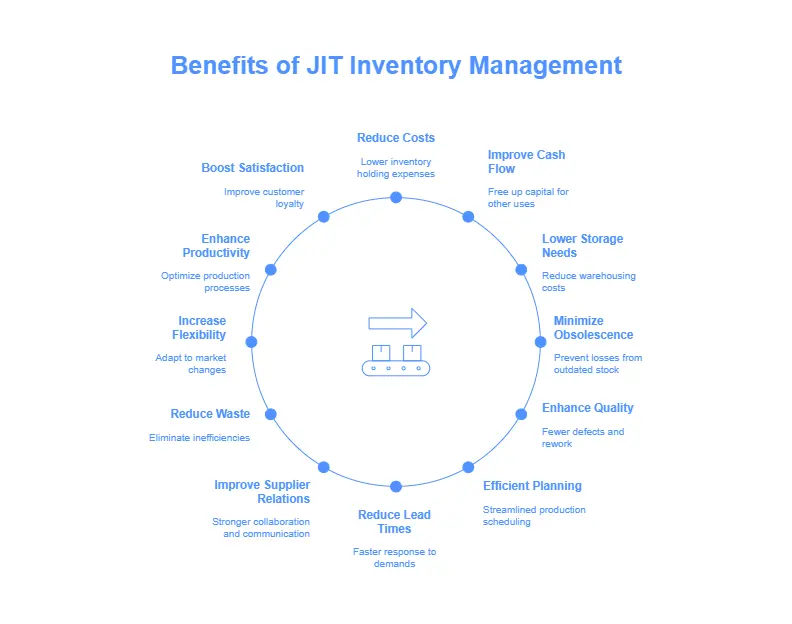

Benefits of Jit Inventory Management

JIT (Just-in-Time) inventory management is an approach that focuses on delivering products or materials exactly when they are needed in the production process, minimizing inventory levels and associated costs. This method offers several benefits to businesses, ranging from cost savings to improved operational efficiency. Let’s explore these benefits in detail:

1. Cost Reduction:

JIT inventory management reduces inventory holding costs, including storage, handling, and obsolescence expenses.

2. Improved Cash Flow:

With lower inventory levels, capital is not tied up in excess stock, allowing businesses to free up cash for other essential purposes.

3. Lower Storage Space Requirements:

Reduced inventory levels require less storage space, leading to cost savings on warehousing and facilities.

4. Reduced Risk of Inventory Obsolescence:

By minimizing inventory levels, the risk of products becoming outdated or obsolete decreases, preventing losses from unsellable stock.

5. Enhanced Product Quality:

JIT emphasizes quality control throughout the production process, resulting in fewer defects and rework, leading to higher-quality products.

6. Efficient Production Planning:

JIT facilitates streamlined production planning and scheduling, ensuring resources are allocated optimally and production runs smoothly.

7. Reduced Lead Times:

By receiving materials or products just in time, lead times are minimized, allowing for faster response to customer demands and reducing waiting times.

8. Improved Supplier Relationships:

JIT requires close collaboration with suppliers, fostering stronger relationships and enabling better communication and coordination.

9. Reduced Waste:

JIT focuses on waste elimination, including excess inventory, overproduction, and transportation inefficiencies, resulting in cost savings and environmental benefits.

10. Flexibility and Adaptability:

JIT enables businesses to respond quickly to changes in demand, market conditions, and customer preferences, fostering adaptability and agility.

11. Enhanced Productivity:

By optimizing production processes, JIT increases overall efficiency, reduces downtime, and improves employee productivity.

12. Customer Satisfaction:

JIT’s ability to deliver products promptly and consistently leads to improved customer satisfaction, loyalty, and potentially increased market share.

These benefits collectively contribute to a lean and efficient supply chain, helping businesses achieve cost savings, improved profitability, and a competitive edge in the market.

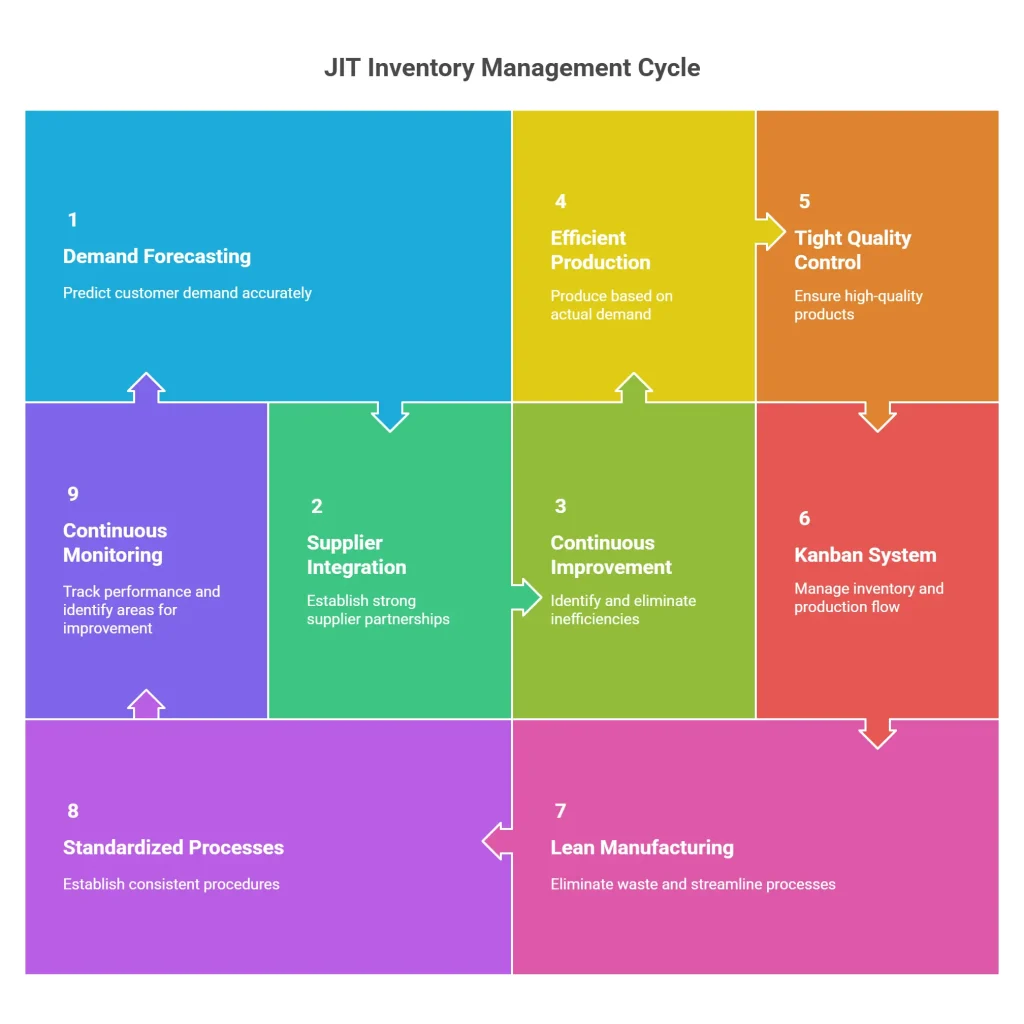

An Overview about Jit Method of Inventory Management

The JIT method of inventory management involves several key steps:

1. Demand Forecasting:

Accurate demand forecasting is crucial in JIT. It helps determine the right quantity of products or materials to produce or order to meet customer demand without excess inventory.

2. Supplier Integration:

JIT relies on close relationships with suppliers to ensure a timely and reliable supply of materials. Suppliers are considered as partners and are expected to deliver quality goods in small, frequent batches, reducing the need for storage space and reducing lead times.

3. Continuous Improvement:

Continuous improvement is a fundamental principle of JIT. It involves identifying and eliminating waste, inefficiencies, and bottlenecks in the production process. By continually analyzing and refining processes, companies can achieve higher levels of efficiency and reduce costs.

4. Efficient Production:

JIT emphasizes producing goods in small, frequent batches based on actual customer demand. This minimizes the need for inventory storage and reduces the risk of obsolete or slow-moving inventory. It also allows for flexibility in responding to changes in demand or product variations.

5. Tight Quality Control:

Quality control is vital in JIT, as defects or errors can disrupt the production process and lead to delays or waste. Implementing robust quality control measures and involving employees in quality improvement initiatives helps ensure that products meet or exceed customer expectations.

6. Kanban System:

The Kanban system is often used in JIT to manage inventory levels and production flow. It uses visual cues, such as cards or signals, to signal when materials should be replenished or when production should be initiated. This system helps maintain optimal inventory levels and prevents overproduction.

7. Lean Manufacturing:

JIT emphasizes lean manufacturing principles to eliminate waste and streamline production processes. This involves reducing non-value-added activities, such as excess inventory, overproduction, and waiting times.

8. Standardized Processes:

Standardization plays a vital role in JIT inventory management. Establishing standardized processes and procedures across the supply chain helps eliminate variations and inefficiencies. Standardization enables consistent quality, reduces lead times, simplifies communication, and improves overall operational effectiveness.

9. Continuous Monitoring and Metrics:

JIT requires continuous monitoring of key metrics to track performance and identify areas for improvement. Metrics such as inventory turnover, order cycle time, on-time delivery, and lead time are closely monitored. Regular performance evaluations help identify bottlenecks, inefficiencies, and areas for optimization.

Overall, the JIT method of inventory management focuses on efficiency, waste reduction, and responsiveness to customer demand. By minimizing inventory levels, streamlining production processes, and maintaining strong supplier relationships, companies can achieve cost savings, improve customer satisfaction, and gain a competitive advantage in the marketplace.

Conclusion

Just-in-Time (JIT) inventory management is a lean approach that focuses on producing goods or delivering services precisely when they are needed, thereby reducing costs and improving efficiency. By minimizing inventory levels, streamlining production processes, and maintaining strong supplier relationships, companies can achieve cost savings and gain a competitive advantage.

JIT requires accurate demand forecasting, supplier integration, continuous improvement, efficient production, tight quality control, and the use of a Kanban system. For businesses looking to implement JIT.

With their expertise in inventory management and software solutions, Qodenext can help optimize inventory levels, streamline processes, and improve overall efficiency. Visit Qodenext now to explore how they can assist you in implementing JIT inventory management and take your business to the next level.

FAQs: Just-in-Time (JIT) Inventory Management

1. What is Just-in-Time (JIT) inventory management?

Just-in-Time is an inventory strategy where materials and products are ordered and received only as needed in the production process, minimizing inventory holding and waste.

2. What are the main benefits of JIT inventory management?

JIT reduces inventory costs, improves cash flow, enhances product quality, boosts productivity, and allows businesses to respond quickly to changing customer demands.

3. What industries commonly use JIT inventory management?

JIT is popular in industries like automotive manufacturing, electronics, retail, aerospace, and food processing—where demand forecasting and precision are critical.

4. What are the risks of JIT inventory management?

JIT can lead to production delays if there are disruptions in the supply chain, such as supplier issues, transport delays, or sudden spikes in demand.

5. How does JIT improve product quality?

JIT emphasizes quality checks at every stage of production. By identifying defects early, it reduces rework, enhances consistency, and improves overall customer satisfaction.

6. What role do suppliers play in JIT?

Suppliers are crucial partners in a JIT system. They must deliver smaller quantities of materials frequently and on time to support the production schedule.

7. Is JIT suitable for small businesses?

Yes, small businesses can benefit from JIT by reducing the capital tied up in inventory and using flexible, demand-driven inventory planning.

8. What is the Kanban system in JIT?

Kanban is a visual scheduling tool used in JIT to signal when more materials are needed. It helps manage workflow, inventory levels, and production timelines efficiently.

9. How does JIT impact lead time?

JIT typically reduces lead time by synchronizing production and delivery schedules, leading to quicker turnaround and faster fulfillment of customer orders.

10. Can technology help in implementing JIT inventory?

Absolutely. Inventory management software, demand forecasting tools, and real-time supply chain tracking systems are essential for executing a successful JIT strategy.