Traditional warehousing is being put to the test in a world where speed is what makes you successful. Businesses don’t want to keep products anymore; they want to move them. Every hour a product sits in a warehouse costs more, slows down delivery, and uses up working capital.

Cross docking is a strategy that many of the world’s most efficient supply chains, like Amazon and Walmart, use. It’s not new, but it’s more important than ever in a time of quick sales and small profits.

What is cross docking, how does it work, and why do companies say it’s the best way to save money in logistics? Let’s make it clear and useful by breaking it down in this blog.

Let’s get started.

What Does Cross Docking Mean?

Cross docking is a logistics method that moves goods from incoming to outgoing transportation with little or no time spent in storage in between.

Instead of unloading, storing, and then reloading products, they are “crossed” across the dock, moving straight from the supplier’s truck to the customer’s delivery truck. Cross docking means turning warehouses into high-speed transfer hubs instead of long-term storage facilities. This cuts down on or even eliminates the time goods spend in storage.

Now that we know what it is, let’s talk about what cross docking means in logistics and how it fits into the bigger picture of the supply chain.

What does cross docking mean in logistics?

When we talk about the meaning of cross docking in logistics, we’re talking about a method that focuses on flow instead of storage. The purpose of a traditional warehouse is to store goods until they are needed. A cross docking warehouse, on the other hand, is meant to move goods as quickly as possible.

This is how it usually goes:

- Manufacturers or suppliers send inbound shipments.

- The items are sorted, put together, or repacked if necessary.

- They are put on trucks right away that are going to customers, stores, or distribution points.

In a lot of cases, it only takes 30 minutes to a few hours to turn around. A cross docking warehouse is a place where goods are transferred, not stored. It’s like a pit stop in a race: fast, accurate, and all about moving.

How to Cross Dock: A Step-by-Step Guide

To get a better idea of what cross docking means in real life, let’s look at a typical workflow:

| Step | Description | Objective |

| 1. Receiving | Goods arrive at the docking terminal from suppliers or factories. | Record arrival and check documentation. |

| 2. Sorting & Segregation | Products are sorted by destination or order requirement. | Match incoming goods to outgoing shipments. |

| 3. Staging | Items are placed briefly in a staging area (not stored). | Prepare for quick transfer. |

| 4. Loading & Dispatch | Goods are loaded onto outbound trucks headed to stores/customers. | Ensure fast turnaround and accuracy. |

The goal is easy: to cut down on the number of times goods are “touched” and the amount of time they spend in the warehouse.

Now that we’ve seen how it works, let’s look at the different kinds of cross docking operations that are used in logistics today.

Different kinds of cross docking

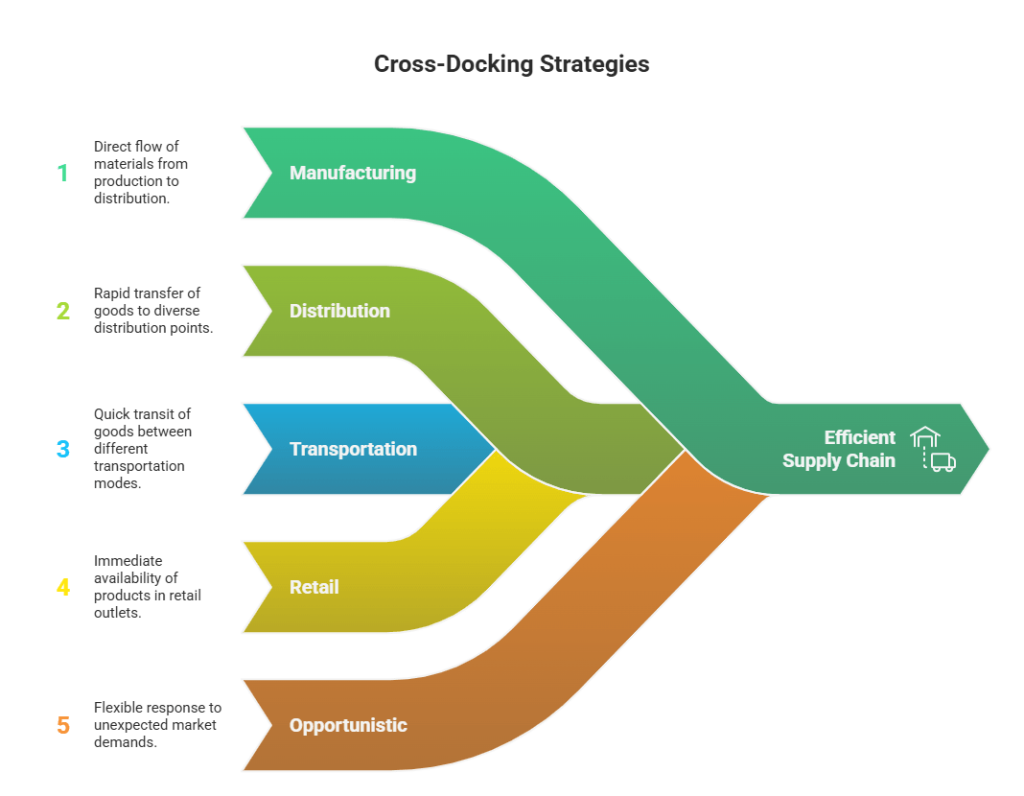

Cross docking is used differently in different industries depending on their needs and schedules. These are the main types:

1. Cross Docking in Manufacturing

Used to move raw materials or sub-assemblies from several suppliers straight to a production line, which cuts down on storage space in the factory.

Example: Toyota and other car companies use cross docking to get parts from suppliers to assembly plants right when they need them for production.

2. Cross docking for distributors

This means combining shipments from different suppliers and sending them as one mixed load to stores or regional hubs.

Walmart was the first to use this method: suppliers bring goods to cross-docking centers, where they are sorted and sent to stores, usually within 24 hours.

3. Cross docking for transportation

Logistics companies use it to combine smaller loads into full truckloads, which cuts down on transportation costs and makes routes more efficient.

For example, DHL uses cross docking at major hubs to move goods between regions quickly, which cuts down on unnecessary transit time.

4. Cross-docking in retail

This helps retailers with more than one store restock quickly. Orders from suppliers are pre-labeled for each store, moved quickly, and sent out the same day.

5. Cross Docking for Opportunistic Reasons

When warehouse management systems find an incoming product that matches an existing outbound order, they send it straight to the customer instead of storing it.

Now that we’ve looked at the different formats, let’s talk about why this strategy is becoming a must-have in fast, low-cost supply chains.

Important Benefits of Cross Docking

Cross docking is appealing because it makes things easier and saves money. This is what gives it strength:

1. Low Costs for Storage

Since products don’t sit in a warehouse, the costs of storing them, like rent, utilities, and maintenance, go down a lot.

2. Quicker Delivery Times

Goods get to customers faster when they don’t have to go through storage and retrieval. This is especially important for e-commerce and things that go bad quickly.

3. Better cash flow

Having fewer goods in stock means less money is tied up, which makes working capital and liquidity better.

4. Less handling and damage

Moving less around the warehouse lowers the chance of human error and product damage, which makes everything better and more reliable.

5. A more efficient supply chain

Cross docking helps suppliers, logistics providers, and retailers work together more closely, which makes the supply network more flexible and responsive.

These advantages are why many big companies see cross docking as a strategic choice rather than an operational one.

Now that we’ve talked about the pros, let’s look at the cons to get a more complete picture.

Problems with cross docking

Cross docking is not a one-size-fits-all solution, just like any other strategy. It needs technology, coordination, and accuracy.

A few of the biggest problems are:

- Tight Scheduling: If shipments coming in and going out aren’t perfectly timed, delays will spread throughout the network.

- High Initial Setup Costs: Cross docking terminals need advanced infrastructure, automation, and trained workers.

- Limited Product Suitability: It works best for items that are in high demand, move quickly, or go bad quickly, not for items that move slowly.

- Dependence on Technology: Needs real-time access to inventory, strong communication systems, and sometimes integration with the Internet of Things.

- Reliability of suppliers: One late truck can throw everything off.

Even with these problems, the benefits of doing things right far outweigh the risks.

We now know what both sides think. Let’s talk about the technology that makes cross docking possible on a large scale.

The Technology That Makes Cross Docking Work

Integrated technology is very important for modern cross docking warehouses to run smoothly.

Here is what usually gives them power:

| Technology | Role in Cross Docking |

| Warehouse Management System (WMS) | Tracks inbound and outbound goods, assigns dock doors, and ensures real-time visibility. |

| Transportation Management System (TMS) | Optimizes routing, carrier scheduling, and shipment tracking. |

| Barcode & RFID Scanning | Enables fast, error-free identification and sorting. |

| Automation & Robotics | Speeds up loading/unloading and reduces manual errors. |

| IoT Sensors | Provide real-time data on vehicle arrival, temperature (for perishables), and dock utilization. |

These technologies work together to make a cross docking warehouse into a synchronized, data-driven operation where every second matters.

Now that we’ve looked at the technical side, let’s see where cross docking fits in best.

When should businesses use cross docking?

Cross docking isn’t right for every operation, but when it is, it’s the best.

Here are the best situations:

- High-velocity goods are things that people always want, like fast-moving consumer goods (FMCG) or best-selling items on e-commerce sites.

- Food, drugs, and other items that need to be kept at a certain temperature are called “perishables.”

- Seasonal surges: How to handle high demand without adding more space to the warehouse.

- Retail replenishment: Quick restocking of stores for items that sell quickly.

- Third-party logistics (3PL): companies that want to get the most work done with the least amount of storage space.

For example, grocery stores like Tesco and Carrefour use cross docking to move fresh fruits and vegetables directly from suppliers to stores every day. This keeps the food fresh and cuts down on the costs of cold storage.

Cross docking is more than just a way to move things around; it’s a way of thinking about always being on the move.

Let’s look at what it really does for business now that we know when to use it.

Why Cross Docking Is Important in Today’s Supply Chains

In today’s fast-paced business world, there is no time for operations that don’t change. Customers want things to happen right away, suppliers want to see what’s going on, and logistics teams have to find a way to meet both needs.

That’s why cross docking has gone from a niche logistics strategy to a key part of the supply chain. It backs:

- Omnichannel fulfillment makes it possible to restock stores and online stores faster.

- Sustainability means using less energy to store things and throwing away less stuff.

- Operational resilience means that shorter cycle times make it easier to deal with problems.

- Customer loyalty: faster delivery makes customers happier and more likely to buy again.

Cross docking may seem like a simple concept, but it has a big effect on efficiency, sustainability, and profitability, making it one of the best logistics practices for the future.

Conclusion

Cross docking is the opposite of traditional warehousing, which is about storing goods. It’s the difference between storing things and making things easier.

Cross docking doesn’t just mean skipping storage; it means redesigning logistics to focus on flow, accuracy, and timing. Customers want things done quickly, and businesses want to be as efficient as possible. The companies that can master this flow will win the supply chain race.

So, if you’re a retailer, manufacturer, or 3PL provider, the message is clear: in logistics today, it’s not about how much you store, but how quickly you move.

FAQs:

1. What does “cross docking” mean in logistics?

It means moving goods directly from incoming to outgoing transport with little or no storage in between, which saves time and money.

2. What does “cross docking warehouse” mean?

A cross docking warehouse is a place where goods can be quickly moved from one place to another, not stored for a long time.

3. Which fields get the most out of cross docking?

Cross docking is used in retail, fast-moving consumer goods (FMCG), automotive, and e-commerce to speed up the time it takes to get products to market and cut down on handling time.

4. What technology makes cross docking work well?

WMS, TMS, RFID, and automation tools make sure that logistics going in and out are coordinated in real time.

5. What are the best things about cross docking?

Less money spent on storage, faster delivery, better inventory turnover, and better supply chain synchronization.