When you think of a factory, you might imagine rows of machines, workers checking controls, and long conveyor belts. But walk into a smart factory today, and you’ll notice how different things look. Machines talk to each other, data flows smoothly between systems, and many processes adjust automatically without anyone pressing a button.

This new way of working is called Industry 4.0 — the stage of manufacturing where technology and intelligence come together. From sensors that track machine health to robots that manage production lines, companies are finding smarter ways to work.

In this article, we’ll look at a few real-world Industry 4.0 examples that show how factories are becoming faster, more efficient, and more sustainable than ever before.

What Is Industry 4.0?

The fourth industrial revolution is called Industry 4.0. It is based on digital innovation and smart automation. The Internet of Things (IoT) connects machines, sensors, and systems so they can collect and share data in real time.

At its most basic level, Industry 4.0 brings together:

- IoT for connecting and seeing things

- Cyber-physical systems (CPS) for making decisions automatically

- Big data and analytics for useful information

- AI for accurate predictions

These new technologies let machines gather data, look at performance, and make changes in real time. The end result is a production ecosystem that knows what it is and can always get better.

This base of connectivity, automation, and insight is what many of today’s successful industry 4.0 examples are built on.

Why Industry 4.0 Matters in Manufacturing

Manufacturers are always under pressure to do more with less. Industry 4.0 helps with that problem by giving them better visibility, predictive insights, and smarter tools for making decisions.

Factories that use these technologies can find problems early, cut down on downtime, and make things with more accuracy. They don’t wait for problems to happen; they plan for them.

These results, which can be seen in top global examples of Industry 4.0, show that digital intelligence is now a key part of operational excellence.

Real-World Industry 4.0 Examples

Now that we know what Industry 4.0 means, let’s look at how different companies are using it in real life. From car makers to tech giants, these Industry 4.0 examples show how smart technologies are helping factories work faster, save energy, and reduce waste.

- BMW – Data-Driven Production

Data can change how things are made today, as seen in BMW’s production lines. Sensors in the Internet of Things (IoT) gather data on vibration, temperature, and torque at each workstation. Then, AI tools look at that data to make sure that quality stays the same and that defects don’t happen.

This method lets BMW act on insights right away and get rid of waste, which is one of the best examples of smart manufacturing in action.

- Schneider Electric – Sustainable Smart Factories

Schneider Electric’s digital factories show how IoT and analytics can help with both efficiency and sustainability. The company uses connected systems to keep track of energy use and production data so that it can improve performance.

By using automation and data integration, Schneider Electric makes its operations more reliable and has a smaller impact on the environment. This industry 4.0 example reflects how digital tools can make manufacturing cleaner and smarter.

- Audi – Digital Twin Manufacturing

Audi has implemented cyber physical systems applications and digital twin technology across several of its production plants. There is a digital copy of each physical process that lets engineers test changes in a virtual environment before making them on the floor.

By combining simulation with reality, this system makes sure everything is accurate, cuts down on downtime, and makes it easier to adapt. Audi’s use of digital twins shows that they are not just ideas for the future, but real solutions that can help businesses get real results.

- General Electric (GE) – Predictive Maintenance through Big Data

GE keeps an eye on high-value equipment like turbines and engines by using connected systems and data analytics. We look at a lot of sensor data to figure out when a part will need to be fixed.

GE has cut down on unexpected breakdowns and made better use of its assets by using big data in manufacturing. This data-driven method shows how analytics can directly improve reliability and cut costs.

- Tata Steel – Smart Factory Leadership in India

Tata Steel has emerged as one of India’s strongest industry 4.0 examples, integrating IoT systems, automation, and data analytics across its plants.

The company’s connected ecosystem makes it easy to keep track of every step in the production process and make the best use of energy. Its success shows how Indian businesses are using global best practices to make their operations more efficient and environmentally friendly on a large scale.

How Industry 4.0 Technologies Work Together

Think of Industry 4.0 as a well-coordinated orchestra. IoT devices collect data, cyber-physical systems interpret it, and analytics platforms turn it into insights.

Technologies like RFID, Machine Vision, and Automation are playing a key role in this transformation, helping industries bridge the gap between physical production and digital intelligence.

Together, these technologies form an ecosystem that continuously learns and improves.

| Technology | Purpose in Manufacturing |

| IoT Sensors | Capture data from machines and environments |

| CPS | Connect digital intelligence with physical processes |

| Big Data | Analyze information for performance and quality |

| AI & ML | Enable predictive and autonomous operations |

| Cloud Systems | Store and manage data centrally |

This collaboration between technologies makes factories more agile, efficient, and responsive to market changes.

Benefits of Adopting Industry 4.0

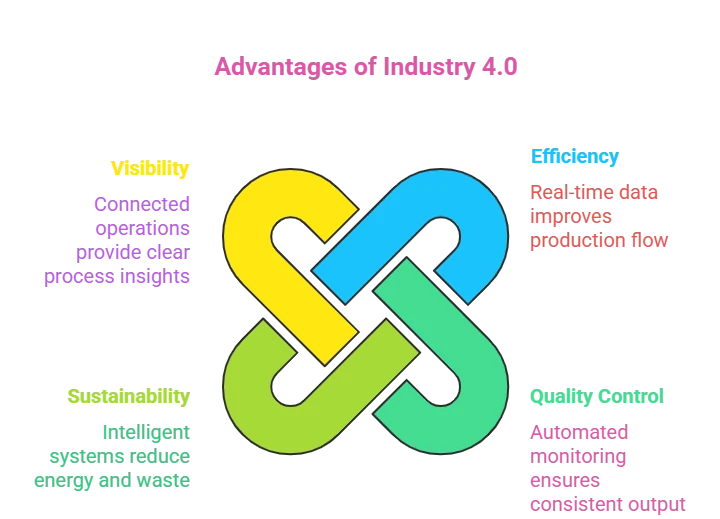

There are many benefits to adopting Industry 4.0:

- More efficient: Real-time data makes production flow better.

- Quality Control: Automated monitoring makes sure that the output is always the same.

- Sustainability: More intelligent systems use less energy and create less waste.

- Visibility: Connected operations make every step of the process clear.

These benefits, showcased through real industry 4.0 examples, show that smart technology is no longer optional; it’s a competitive necessity.

Challenges in Implementation

While the benefits are evident, the journey toward Industry 4.0 requires thoughtful planning. Common challenges include high initial investment, integration with legacy systems, and the need for skilled professionals who can manage digital operations.

However, most manufacturers overcome these barriers through phased adoption — starting small, proving results, and scaling gradually across operations.

The Future of Smart Manufacturing

The next phase of Industry 4.0 will focus on autonomy and intelligence. As robotics, AI, and analytics evolve, every manufacturing production line will become more self-reliant and responsive.

Factories will make independent decisions, optimizing production, managing supply chains, and conserving energy automatically.

Future industry 4.0 examples will show even deeper integration between digital intelligence and physical manufacturing, leading to truly adaptive, self-correcting systems.

Conclusion

Manufacturing has always been about making things better, from machines to automation to intelligence. Industry 4.0 is the next big step, where systems that are connected and data-driven insights change the way we think about efficiency.

Every success story, from BMW and Audi to Schneider Electric and Tata Steel, shows that smart technology is changing how we make, move, and measure things.

These examples of Industry 4.0 show us that the future of manufacturing isn’t coming; it’s happening right now, with each new idea.

FAQs(Frequently Asked Questions)

What are the biggest challenges manufacturers face when implementing Industry 4.0?

The main challenges include high initial investment, complex system integration, data security concerns, and the need to upskill the existing workforce.

How can small and mid-sized factories adopt Industry 4.0 technologies?

Smaller factories can begin with affordable IoT devices, cloud-based analytics, and modular automation solutions that deliver measurable ROI before full-scale deployment.

What skills are required to manage smart factory systems?

Managing a smart factory requires professionals skilled in data analytics, digital operations, industrial automation, and process optimization.

How does Industry 4.0 contribute to sustainable manufacturing?

Industry 4.0 promotes sustainability by reducing waste, improving resource utilization, and enabling energy-efficient, data-driven production processes.

Why is big data important in Industry 4.0?

Big data helps manufacturers analyze information from multiple sources, uncover inefficiencies, and make data-backed decisions for process improvement.