Every warehouse needs accurate inventory data to run smoothly. When stock numbers are right, things move smoothly, orders are filled on time, and making decisions is easier. But if your data is wrong, it can cause stock to be misplaced, delays, and extra costs.

In the past, businesses would stop working and check every item in the warehouse to do a full physical inventory count. This gave a quick look at accuracy, but it took a lot of time and work.

Cycle counting is becoming more common in modern warehouses. It’s a flexible and ongoing method that helps keep things accurate without stopping work.

Let’s look at what is cycle counting, how it differs from physical inventory, and which method is best for your business.

What Is Cycle Counting?

Cycle counting is the process of checking small parts of inventory on a regular basis. Instead of checking everything at once, some SKUs are counted every day, week, or month to make sure the records are still correct.

You could check a few hundred items every day instead of shutting down for two days to count all of them. This keeps your business going while making sure that the accuracy stays the same.

Knowing what cycle counting is helps warehouses keep track of their inventory in real time and make big annual counts less work.

Cycle Counting vs Full Physical Inventory

Both methods want to be accurate, but they go about it in different ways. Cycle counting makes sure that the numbers are always right, while physical inventory only checks them once.

To help you decide, here’s a simple comparison:

| Aspect | Cycle Counting | Full Physical Inventory |

| Definition | Counting small portions regularly | Counting all items at once |

| Operational Impact | Minimal interruption | Requires full shutdown |

| Frequency | Ongoing throughout the year | Once or twice a year |

| Accuracy Over Time | Continuous and up to date | Accurate only during the count |

| Team Involvement | Small, rotating staff | Full team participation |

| Ideal For | Large or fast-moving warehouses | Smaller setups or audits |

While cycle counting vs full physical inventory isn’t about one being better than the other, cycle counting offers more flexibility and less downtime for most modern operations.

How Often Should You Do Cycle Counting in a Warehous

How often you count cycles depends on how big your warehouse is, what kinds of items you have, and how quickly they sell.

Check high-value or fast-moving items once a week or every other week. Check lower-value or slow-moving items once a month or every three months. The trick is to find a balance between time and accuracy.

Most warehouses use an ABC analysis model to plan how often to count different SKUs.

Cycle Counting Frequency by SKU Category

To make counting easier, warehouses group items by how important they are and how quickly they move.

We count A-items often because they are valuable and sell quickly. Every month, B-items are checked, but C-items, which move slowly, can be checked every few months.

Setting the right cycle counting frequency by SKU category keeps your most important products accurate and saves you time and effort.

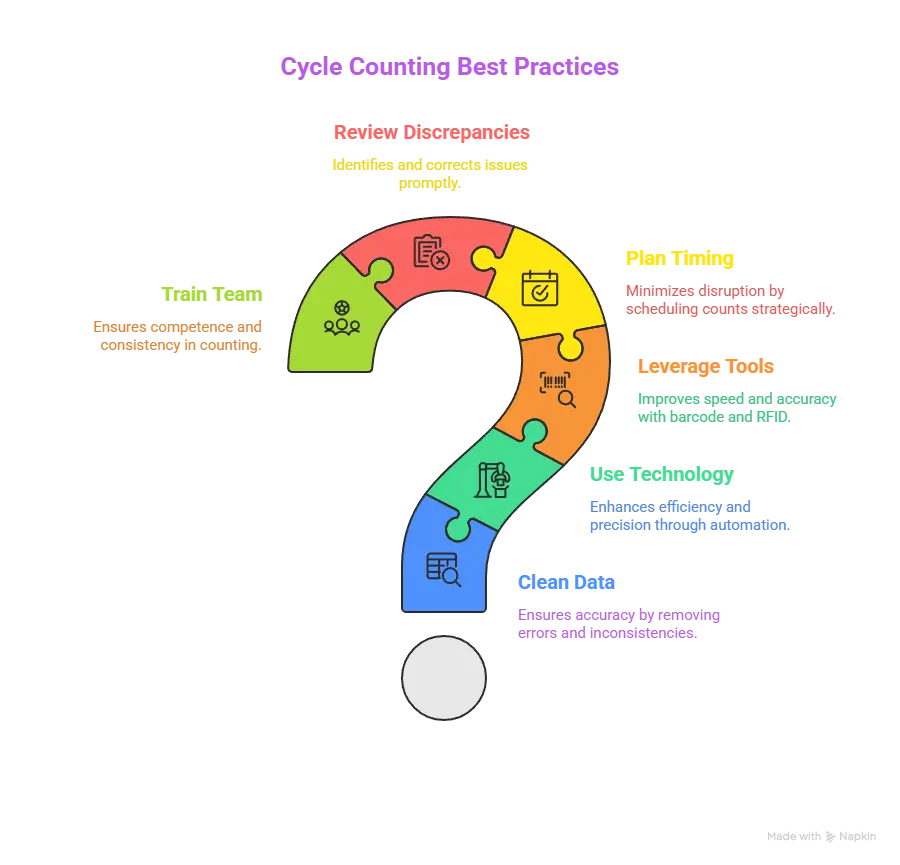

Cycle Counting Best Practices

When you decide to start cycle counting, there are a few important things you can do to make your system work better:

- Clean your data first: Before you start, make sure your ERP or WMS data is correct. Your counts will also be affected by any mistakes that are already in your system.

- Use technology wisely: Get good cycle counting best practices software that can set up schedules, give out counting tasks, and sync results right away.

- Leverage barcode and RFID tools: Devices like barcode scanners or RFID systems reduce manual errors and make counting faster.

- Plan your timing: Set up your schedule during off-peak or slower times so that your business doesn’t have to stop.

- Review and act on discrepancies: Don’t just fix the numbers that don’t match up; find out why they don’t match and fix the problem at its source to make sure it doesn’t happen again.

- Train your team: Make sure that everyone knows how to count, how to use the tools, and why being accurate is important.

- Measure and refine: Look at your results often and change your process to make it more efficient and consistent over time.

When to Use Full Physical Inventory

Cycle counting is flexible and efficient, but there are times when a full physical count is still useful.

A full count gives you a new, reliable starting point if you’re changing warehouse management systems, getting ready for a financial audit, or moving operations. It’s also helpful when there have been big changes to a process or when the data is no longer reliable.

You can go back to cycle counting once that baseline is set up to keep things accurate with as little trouble as possible.

How to Choose the Right Method

Your business type, resources, and goals will help you decide whether to do cycle counting or a full physical inventory.

Cycle counting is usually the best choice if your warehouse is big, busy, and has a lot of automation. It keeps data up to date, cuts down on downtime, and stops big mistakes from happening.

A full inventory count once a year might still make sense for smaller businesses or businesses that have to follow strict audit rules. Many businesses actually use both: they do regular cycle counts all year long and then do a physical inventory to double-check.

With this combination, you get the best of both worlds: ongoing accuracy and full annual validation.

Conclusion

The key to running a warehouse well is keeping track of your inventory accurately. Cycle counting keeps things accurate all the time, cuts down on downtime, and gives you a better view than full physical counts.

You can keep your data accurate all year long and keep your business running smoothly by defining what cycle counting is, setting the right cycle counting frequency by SKU category, and using modern tools to make your process easier.

With the right mix of technology, consistency, and training, your warehouse will never lose track of what matters most: your inventory.

FAQs

1. What tools make cycle counting easier?

Barcode scanners, RFID tags, and software that follows best practices for cycle counting all make things faster and more accurate.

2. Can small warehouses use cycle counting?

Yes, even small teams can do regular counts by splitting up the stock into smaller groups.

3. How do you decide which SKUs to count first?

Begin with items that are worth a lot or sell quickly, and then move on to less important ones.

4. Does automation help in cycle counting?

Real-time data capture makes counting faster and less likely to be wrong..

5. Can cycle counting replace annual audits completely?

No, it makes you less dependent, but annual audits are still necessary for financial compliance.