If you’re in manufacturing, logistics, or retail, you know the pressure never stops. Customers want faster delivery, costs continue to rise, and it feels like the entire global market can flip on a dime every Tuesday. The traditional processes of business in which paper, manual data entry, and leisurely human approvals were commonplace are just not able to keep pace. But the answer is in sight, and it’s already here, disrupting whole industries: supply chain automation.

Supply chain automation isn’t just robots replacing people; it’s smart tech empowering humans to work smarter, faster, and with fewer mistakes. So here is the strategic pivot that converts a slow, error-prone, cost-heavy supply chain into a nimble, data-powered, highly cash-generative machine.

This definitive guide will explain exactly what the supply chain automation is in 2025. We’ll get into all the big advantages of automating your supply chain, what technology is enabling the future of supply chain automation, and how to use the best supply chain automation software to revolutionize how you do business today.

Defining the Revolution and Its Benefits

At the most fundamental level, supply chain automation is executing predictable, repetitive, and complicated activities within the supply chain using technology without or with minimal human intervention.

Just consider a trivial task such as scanning a barcode:

• The Old School:

A human worker picks up a paper manifest, looks the item up on it, unkeys the number in a computer, types the number in, and checks a box. It’s slow, and it’s prone to typos.

• The Automated Way:

A drone or an automated conveyor belt brings the item before a fixed scanner, which reads an RFID tag or 2D code instantly. The information is captured in the centralized system, and that triggers the next stage (sorting, dispatch, etc.).

From ordering a raw material to delivery of the final product to the customer’s doorstep, this automated procedure is applicable to every process. It’s an automated supply chain management system that’s faster, cheaper, and exponentially more accurate than anything you could ever do by hand.

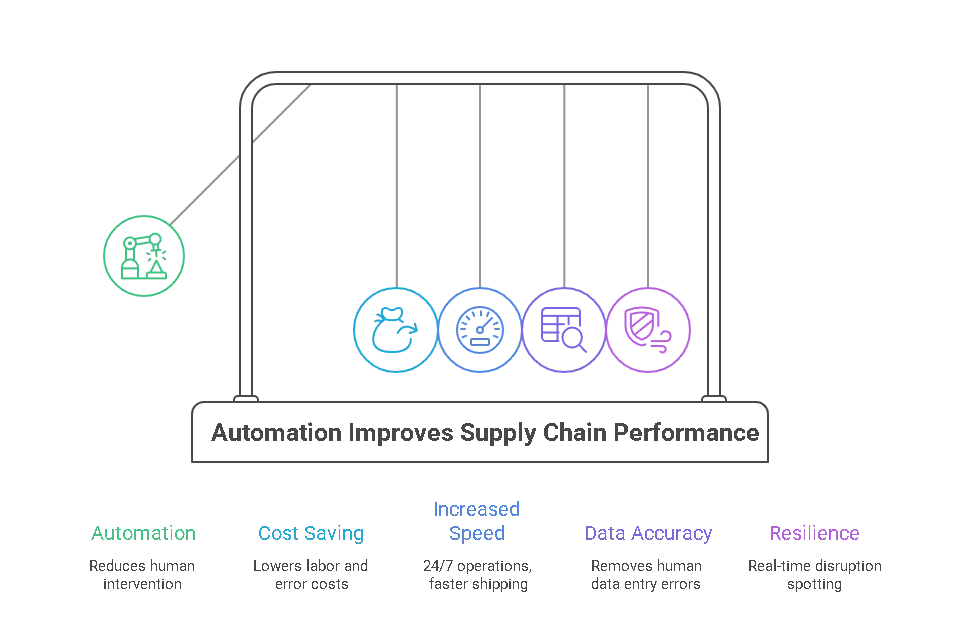

The Benefits of Automation in Supply Chain

Transitioning to supply chain automation is not optional; it’s critical for survival. The benefits of automation in the supply chain extend beyond cost savings; they reshape efficiency, resilience, and customer satisfaction across every touchpoint. The benefits are

1. Cost Saving:

Automation reduces labor costs and significantly curtails the cost of rectifying errors, which can mean re-shipping and customer refunds.

2. Increased Speed and Throughput:

Because automated systems can work 24 hours a day, seven days a week without human fatigue, the time you can expect an order to be moving from your warehouse floor to the shipping dock drops rapidly.

3. Improved Data Accuracy:

Technology removes human errors from counting inventory and entering data. This results in full inventory visibility, which is the essential backbone for agile decision-making.

4. Robust, Agile, and Resilient:

To be able to spot delays or disruptions, even in real time, on the dashboard, and then to pivot, reroute products or manufacturing, and have a supply chain that is that resilient against global events, well, it’s priceless.

Key Aspects of the Automated Supply Chain Management System

An automated supply chain management system touches every part of the product journey. Here is a look at the five major areas where automation is fundamentally changing the game:

A. Warehouse and Fulfillment Automation

The warehouse is usually the first area that companies ramp up their supply chain automation initiatives because the activities are monotonous and high in manpower needs.

• Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs):

These robots transport pallets, shelves, and containers across the warehouse floor. Modern AMRs navigate intelligently using sensors and AI, safely moving around humans and obstacles.

• Automated Storage and Retrieval Systems (AS/RS):

These advanced systems employ cranes or shuttles in storing and retrieving products in and out of pallet-racked systems, with the added benefit of maximizing the vertical space.

• Sorting Systems:

High-speed conveyors and camera-based systems instantly read package information and sort thousands of items per hour to the correct shipping lane.

B. Inventory Management and Tracking

The most important data of any supply chain is knowing exactly what you have and where it is. Automation makes this instantaneous and perfect.

• RFID (Radio-Frequency Identification):

With this technology the scanning is done automatically. Tags affixed to products or pallets are automatically read by fixed or handheld scanners, providing real-time visibility and perfect inventory counts. (See our Comprehensive Traceability Solutions at Qodenext to learn how we take this to the next level through this feature).

• IoT Sensors:

Attaching small sensors to high-value goods tracks their exact location, temperature, and humidity, ensuring product quality during transit.

C. Procurement and Ordering

Automation is not only on the shop floor; it’s in the office, too, particularly in the challenging area of procurement.

• Predictive Analytics for Automated Reordering:

Supply chain automation software can use predictive analytics and real-time inventory levels to automatically create purchase orders for replenishment of low-stocked products. This prevents stockouts without having to involve personnel.

• Invoice Processing (RPA):

Robotic Process Automation (RPA) uses software robots to read invoices, check them against purchase orders, and enter the data into the accounting system, reducing tedious administrative work.

D. Logistics and Transportation

Delivering products from Point A to Point B is intractable, but automation does give us route optimization and capacity management.

• Route Optimization Software:

Sophisticated techniques are applied to real-time traffic, delivery time windows, and fuel prices to generate the best routes.

• Automated Document Generation:

Customs forms, bills of lading, and shipping labels are generated instantly and without error, speeding up border crossings and regulatory compliance.

The Future of Supply Chain Automation (2025 and Beyond)

The speed of evolution in supply chain automation is picking up pace. The future of supply chain automation will be defined by intelligence, integration, and adaptability, making it a cornerstone of competitive advantage. Intelligence and integration are two key priorities when it comes to the future of supply chain automation.

A. Hyper-Intelligence: AI and Machine Learning

Next-generation solutions of automated supply chain management systems will increasingly take advantage of AI being based not just on doing a task over and over again (simple automation) but also on deciding the best course of action (intelligent automation).

• Predictive Maintenance:

AI constantly tracks the health of factory machines to foresee when a part will fail and prevent costly downtime.

• Cognitive Forecasting:

I take into account thousands of external variables at the same time and generate demand forecasts that are never more accurate than those created by statistical models or humans.

B. Hyper-Integration: The Digital Twin

The ultimate goal for the future of supply chain automation is the digital twin.

• What it does:

A digital twin is an end-to-end virtual copy of your physical supply chain, from the entire factory floor layout through to global shipping routes.

• How it works:

All this real-world data is fed into this digital model in real time. Planners can run “what-if” scenarios in the Digital Twin: “What if we double production next week?” The result is flawless planning and a perfect, risk-free preview of the financial and logistical outcome.

Selecting and Deploying Supply Chain Automation Software

You need to “go big” to get it right Unless you have the right supply chain automation software in place, trying to introduce supply chain automation becomes an exercise in frustration.

A. The Technology Stack

The technology for automated SCM systems is often categorized into three supportive entities:

1. ERP (Enterprise Resource Planning):

The core system for all business processes. It needs to be the single source of truth for all the data that has been automated.

2. WMS (Warehouse Management System):

Application for day-to-day warehouse execution and integration with warehouse automation.

3. Automated Data Collection Tools:

The hardware and software that creates the automation at the ground. This is where Qodenext excels, providing:

- High-Speed Scanners & Readers:

Very important for real-time, error-free data capture.

- RFID Systems:

We are able to provide real-time, non-line-of-sight tracking for perfect inventory counts.

- Machine Vision Systems: Automated inspection to ensure quality control without slowing down an automated production line.

B. Key Considerations Before You Automate

Before you invest heavily in supply chain automation hardware and software, pose these critical questions:

• Data Accuracy:

Automation relies on perfect data. If you put automated software on top of poor data, you just automate mistakes faster. Start by improving Smart Inventory Accuracy with WMS and traceability.

• Compatibility:

Will this new supply chain automation software integrate with our existing ERP and WMS? When systems don’t talk, new manual processes are created to “fill in” the separations.

Conclusion: Mastering the Age of Supply Chain Automation

The transition to supply chain automation is the biggest competitive challenge and opportunity for companies today. It’s because of speed, accuracy, and resilience that are not achievable using manual methods.

Through the strategic adoption of an automated supply chain management system enabled by intelligent supply chain automation software along with the fundamental data capture tools that Qodenext offers, you will realize huge benefits of automation in supply chain, from cost savings to faster decision-making, while preparing for the future of supply chain automation. You will reduce costs, thrill customers with speed, and future-proof your business.

The next generation of supply chain automation is here, and it is for those companies who opted for paper and spreadsheets versus robots and real-time data. It’s time to stop considering automation as a cost and start considering it as the best investment you can make in the future profitability and resilience of your business.

Frequently Asked Questions (FAQs)

1. What is Supply Chain Automation?

Supply chain automation is the application of technology and software to supply chain functions to minimize human intervention in monotonous and time-intensive activities. The aim is to boost speed, minimize errors, and enhance efficiency end-to-end, from order processing to delivery.

2. What are the three types of automation in the supply chain?

The supply chain itself has three main types of automation:

- Physical Automation:

Robotics, machinery, etc. (e.g., AGVs, automated storage systems).

- Process Automation:

A style of software that automates business processes (e.g., RPA for invoice processing).

- Information Automation:

In this, sensors and data tools are used to provide up-to-date status (e.g., RFID and IoT for monitoring).

3. How to automate supply chain management?

In a phased approach, you can automate supply chain management:

- Make Data Diligent: Use tracking equipment (such as Qodenext’s scanners or RFID) to gather impeccable data.

- Introduce Software:Once again, the supply chain management software (think WMS and TMS) is the solution that will automate the supply chain.

- Unify: Integrate your new software and hardware into your mainline ERP to work as one cohesive, automated supply chain management system.

- Scale Gradually: Start by automating one high-impact process, then branch out.

4. What are examples of supply chain automation tools?

Your supply chain toolkit should include:

- WMS (Warehouse Management System):

A software package that helps to control the warehouse operations.

- AMRs/AGVs:

Autonomous mobile robots for transporting materials.

- RPA software:

To remove the need for human intervention in non-core activities.

- RFID Readers:

Enable automated inventory tracking and counting.

5. What are common supply chain automation examples in a warehouse?

Common examples include the use of:

- Automated Storage and Retrieval Systems (AS/RS):

Store and retrieve product items from high-bay racks.

- Automated Conveyors:

Transport items to sorting stations.

- Vision Inspection Systems:

For automated quality and label verification of products on the line.

6. How important is AI to the future of supply chain automation?

AI will shift automation from mindless repetition to intelligent decision-making. It will be the source of predictive maintenance and extremely accurate cognitive demand forecasting, as well as autonomous inventory rebalancing, all with minimal human supervision.

7. Does automation immediately reduce supply chain costs?

Yes, but you will make the money back in that way. Capital costs go down in your centralized distribution facility as you think your labor cost for performing the specific automated task decreases; however, the full benefit of an automation in SCM is experienced as an accumulation when you gain efficiency, make fewer errors, and reduce inventory costs, and when you do it for 1 to 3 years.

8. How does supply chain automation enhance customer satisfaction?

Picking, packing, and shipping faster is guaranteed with automation, and continuously so, 24/7. And perhaps more importantly, the very high accuracy achievable with an automated system reduces the likelihood of delivering the wrong product to the customer on time, which is very important for brand loyalty.

9. What’s the largest challenge to building a successful automated supply chain management system?

The biggest hurdle is the cost of the technology, but more organizational and data. It’s not uncommon for companies to find it challenging to adopt new supply chain automation software alongside older legacy systems (think: ERPs) and train their current workforce to handle the complex new automated workflows.

10. How does Qodenext’s traceability support supply chain automation?

Qodenext’s traceability solutions provide the real-time information necessary for automation to work. By using RFID and high-speed scanners, we ensure every asset is digitally tracked, giving the automated systems the perfect data they need to make flawless decisions about picking, sorting, and inventory management.