We live in a world where real-time data collection isn’t just a competitive advantage. It’s a necessity. And right at the center of this shift is a technology that’s been quietly evolving behind the scenes: RFID data capture.

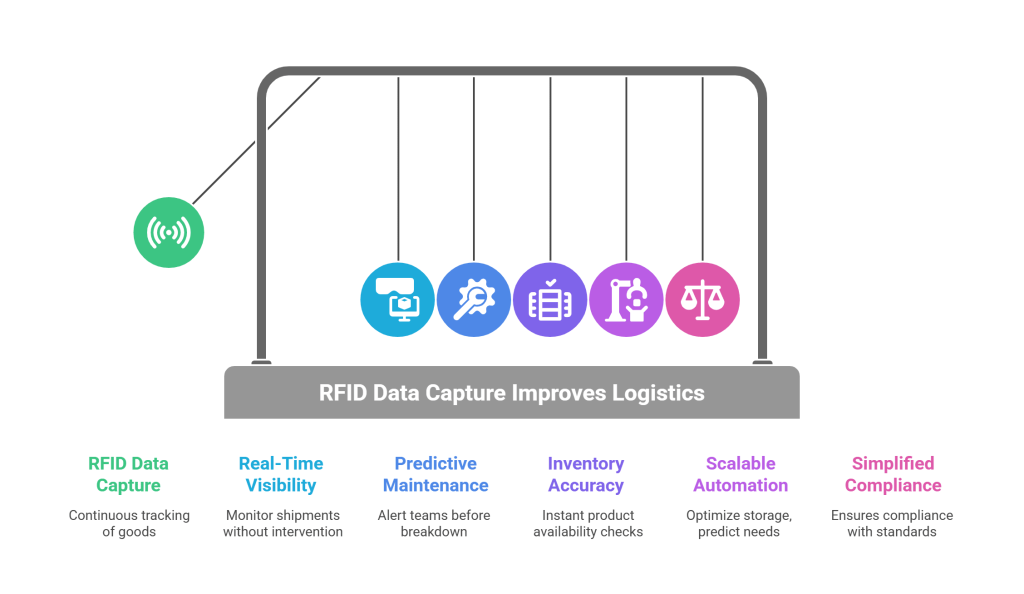

From retail stores and hospitals to massive logistics hubs, RFID (Radio Frequency Identification) has become the backbone of data-driven transformation strategies. But in 2025, it’s no longer just about tracking packages or scanning tags – it’s about enabling automated data capture solutions that are fast, frictionless, and fully integrated into broader systems.

Let’s break down how this silent tech hero is powering the next wave of digital transformation in logistics and beyond.

What is RFID Data Capture and Why is It Suddenly Everywhere?

RFID data capture involves using radio waves to read and collect information stored on a tag attached to an object. Think of it as a supercharged barcode scanner that doesn’t need direct sight and can read dozens (even hundreds) of items in seconds.

Unlike traditional scanning methods that rely on manual effort or visual alignment, RFID can:

- Scan without line-of-sight

- Capture bulk data instantly

- Integrate with backend systems for real-time data collection

This shift from manual to automated data capture solutions – has become a game-changer, especially for industries managing thousands of moving pieces.

Let’s Take an Example: Decathlon

Global sports retailer Decathlon uses RFID to track over 90% of its products from production to sale. Every item is tagged at manufacturing, enabling instant updates on stock levels at every store. When a customer buys a product, the system auto-deducts it from inventory – no human scanning required.

The result? Drastic reduction in stockouts, enhanced customer satisfaction, and the kind of agility only possible with real-time data collection.

Now that you understand what RFID data capture is, let’s explore how it’s redefining business operations across industries.

1. Real-Time Visibility Across the Supply Chain

In logistics, knowing “where is my shipment right now?” is a million-dollar question – literally. Traditional methods like barcodes or even GPS can be slow, error-prone, or incomplete.

With RFID data capture, companies get continuous tracking of goods across warehouses, transit, and delivery. Every time a tagged item passes through a gate, dock, or RFID-enabled zone, its location is automatically recorded.

This helps teams:

- Monitor shipments without human intervention

- Reduce misplacements or theft

- Ensure digital transformation in logistics through transparency

Example: DHL has deployed RFID to monitor high-value shipments in its Life Sciences division. This ensures temperature-sensitive medicines are not just tracked, but also monitored for compliance in real time—hugely important for healthcare logistics.

Ready to see how this data improves efficiency? Let’s get into predictive analytics.

2. Enabling Predictive Maintenance and Planning

The true power of data-driven transformation isn’t just knowing what’s happening—it’s knowing what will happen next.

When RFID tags are placed on equipment, tools, or assets, companies can analyze usage patterns over time. Combined with AI, this enables predictive maintenance—machines can alert teams before a breakdown.

In sectors like manufacturing or aviation, this means:

- Less downtime

- Fewer unplanned disruptions

- Safer operations

Example: Airbus uses RFID to tag thousands of tools and parts. Before RFID, their technicians often spent hours locating specific tools. Now, everything is instantly traceable – reducing maintenance time and costs while keeping aircrafts flight-ready.

3. Enhancing Customer Experience and Inventory Accuracy

RFID doesn’t just help behind the scenes. It’s also transforming how businesses engage with customers.

Retailers, for example, are using automated data capture solutions to offer click-and-collect in under 30 minutes or instant product availability checks across store networks. And this is only possible with 99.9% inventory accuracy powered by RFID data capture.

Example: Zara, the global fashion retailer, rolled out RFID across all its stores. Staff can scan entire shelves in seconds, replenishment is automated, and customers rarely face “out of stock” disappointment. That’s not just operational efficiency—it’s brand loyalty.

With this level of accuracy, businesses can build better front-end experiences while running leaner backends.

Alright, now let’s talk about scalability and why this matters more in 2025 than ever before.

4. Scaling Up with Automation and AI

As industries scale, manual tracking becomes a bottleneck. You can’t track 500,000 pallets with spreadsheets. This is where RFID data capture paired with AI enters the picture.

Smart warehouses are now combining RFID with machine learning algorithms to optimize storage, predict inventory needs, and even automate reordering.

When RFID data streams into ERP or WMS systems, AI can:

- Forecast demand spikes

- Spot inefficiencies in warehousing

- Trigger alerts when stock is running low

This makes AI + RFID a powerful combo for end-to-end data-driven transformation.

Example: In India, BigBasket has tested RFID at their fulfillment centers to improve order accuracy and reduce manual picking errors. With growing online demand, such automated data capture solutions are no longer optional – they’re survival tools.

So what are the signs that a business is ready for this level of transformation? Let’s look at a table for quick insight.

Signs You’re Ready for RFID-Driven Automation

| Challenges You Face | RFID Benefit |

| Inaccurate stock data | Instant, real-time inventory updates |

| Manual data entry & human errors | Automation reduces input mistakes |

| Loss/theft of assets | RFID-based tracking & alerts |

| Inability to scale operations fast | Systemized tracking with minimal staff |

| Delayed shipments & missing items | Transparent, end-to-end visibility |

If you tick more than 2 boxes above, RFID may be the best next step in your digital transformation in logistics.

5. Compliance, Audits, and Accountability Simplified

One area companies often overlook? Auditing and compliance.

With RFID, every item’s journey is logged – who handled it, when, where. For industries like pharma, food, or automotive, this kind of real-time data collection ensures compliance with government and international safety standards.

If there’s a recall, companies don’t have to halt operations – they can trace exactly which batches were affected, in seconds.

Let’s now tie it all together with the future outlook.

The Future of RFID: Smaller, Smarter, Cheaper

RFID tech has matured. In 2025, it’s:

- Cheaper (tags cost less than $0.05 in bulk)

- Smaller (fit into labels, packages, or even fabrics)

- Smarter (integrated with AI and cloud dashboards)

This is leading to a rise in logistics automation India, where SMEs and mid-sized businesses are adopting RFID to compete with larger players. RFID is no longer an enterprise-only solution – it’s scalable for all.

As cloud computing, AI, and IoT converge, RFID data capture becomes the foundational layer enabling these systems to talk to each other and act in real-time.

FAQs: How RFID Is Powering Smarter Supply Chains in 2025

1. How does RFID differ from barcode scanning in a logistics setup?

RFID doesn’t require line-of-sight and can scan multiple tags at once, making it far faster and more efficient than traditional barcode scanning in high-volume logistics.

2. Is RFID technology affordable for small businesses?

Yes! Costs have dropped significantly. Low-cost passive tags and open-source platforms have made automated data capture solutions accessible to SMEs and startups, especially in regions like India.

3. Can RFID be integrated with AI and existing ERP systems?

Absolutely. Many modern ERPs now support RFID plug-ins. When combined with AI, RFID systems can deliver predictive insights, improving both operations and planning.

4. What industries can benefit the most from RFID-driven supply chain solutions?

Industries like retail, pharmaceuticals, food and beverage, automotive, and electronics benefit greatly due to their need for traceability, regulatory compliance, and real-time inventory management.

5. How does RFID improve cold chain logistics?

RFID technologies allow for continuous temperature and humidity monitoring. This ensures sensitive products such as vaccines and perishables stay within required conditions, reducing spoilage and minimizing compliance risks.

6. Can RFID systems handle high-volume inventory environments?

Absolutely. RFID can scan hundreds of tags at once without manual intervention, making it ideal for large warehouses and busy distribution centers.

7. What is the typical lifespan of an RFID tag?

Most RFID tags, especially passive ones, last for several years if handled under proper environmental conditions. However, exposure to extreme temperatures or chemicals can shorten their lifespan.

Conclusion

What was once just a tracking tool is now the backbone of digital transformation in logistics, helping enterprises adapt to uncertainty with clarity.

As brands like Zara use RFID to unify inventory across physical and digital stores, and DHL integrates automated data capture solutions in their warehouses, one thing becomes clear: the era of intelligent supply chains is here – and RFID is leading the charge.

If your business still views RFID as “optional,” 2025 might just leave you behind.